Bagging machine for formaldehyde adsorption particles

A formaldehyde adsorption and bagging machine technology, applied in the directions of packaging, transportation and packaging, packaging item types, etc., can solve problems such as inability to guarantee accuracy and no other material support, and achieve the effect of ensuring accuracy and preventing clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

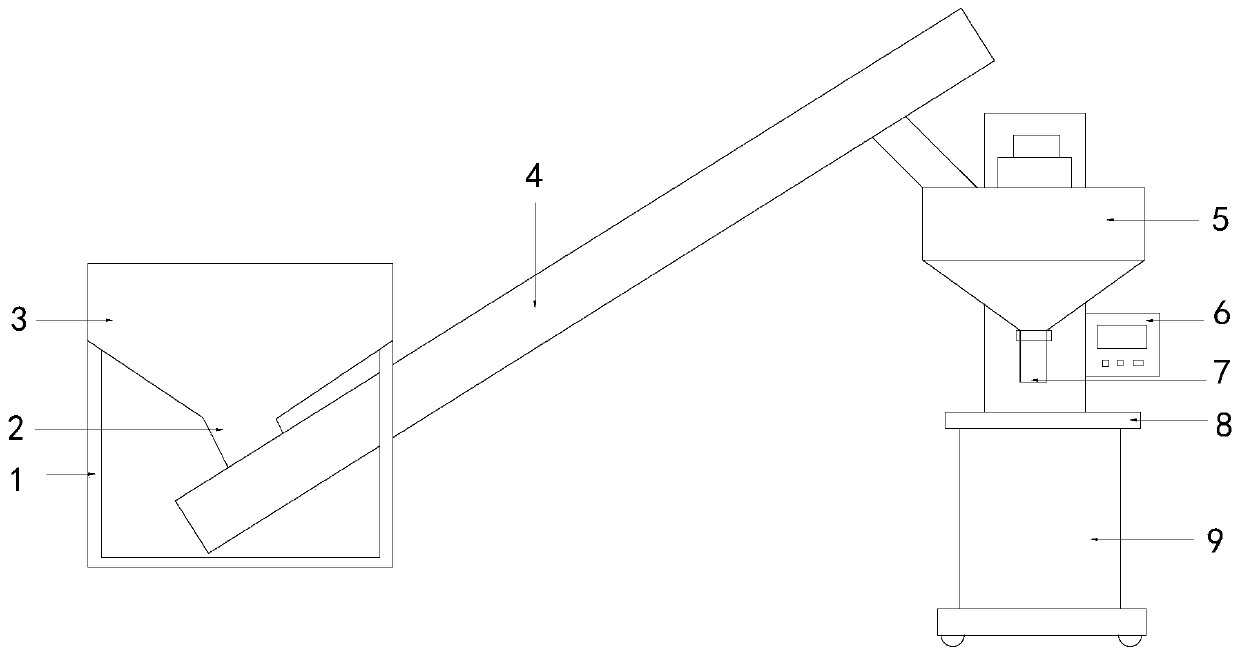

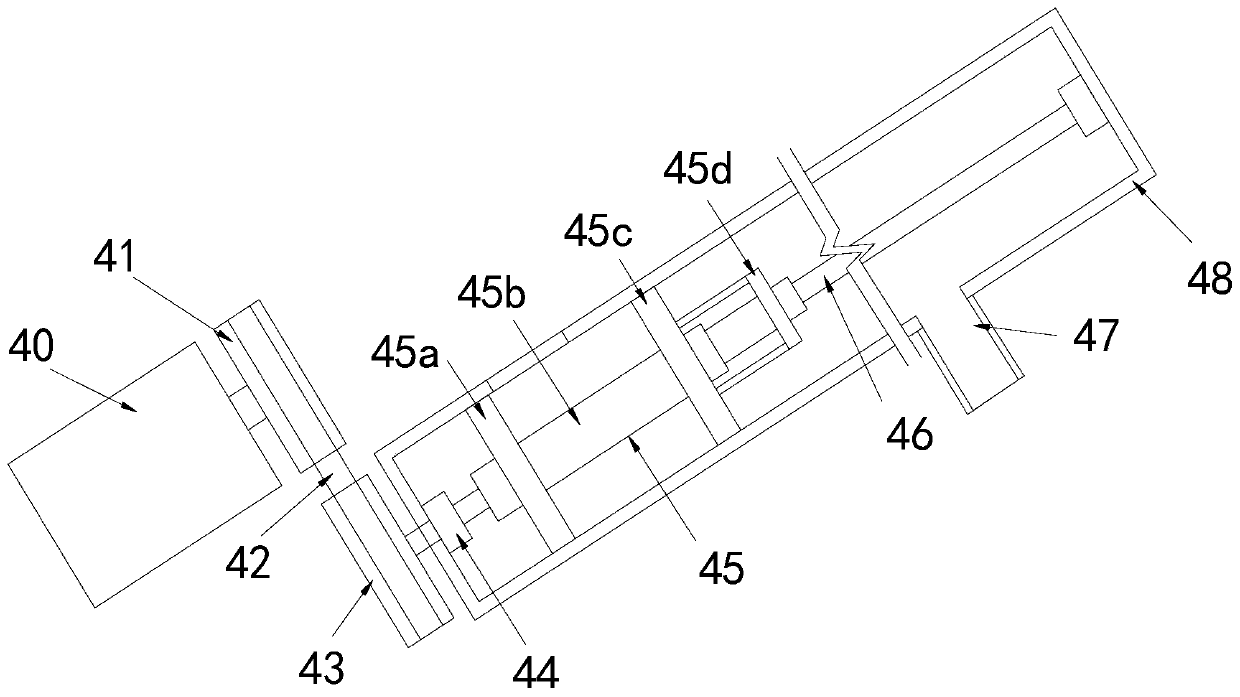

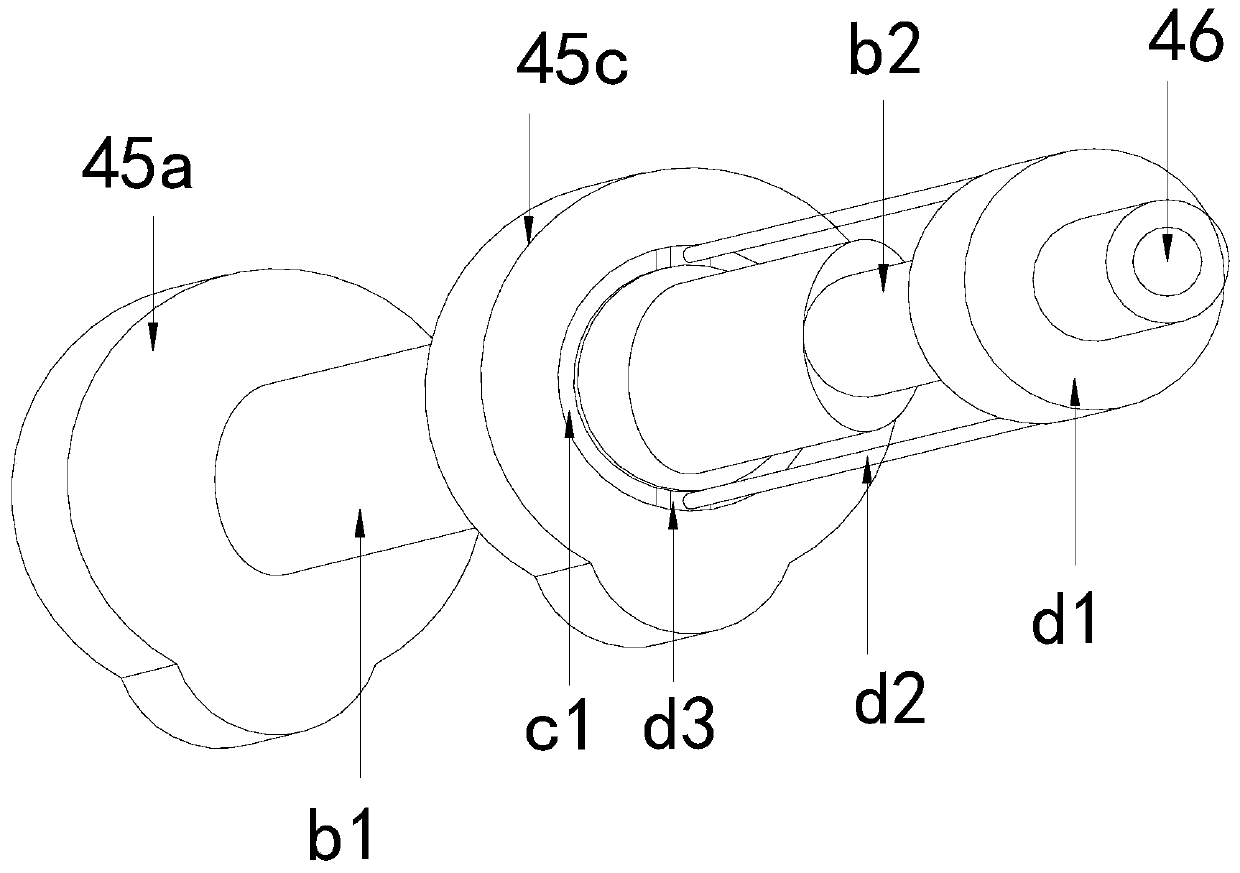

[0024] See Figure 1-2 , The present invention provides a technical solution for a bagging machine for formaldehyde adsorption particles: its structure includes a bracket 1, a meter 2, a feed barrel 3, a feeder 4, a storage box 5, an electric control box 6, a discharge port 7, Workbench 8, base 9, said base 9 is provided with workbench 8, said discharge port 7 is set above workbench 8 and connected to the bottom of storage box 5, said storage box 5 top and feeder 4 The top is connected, the bottom of the feeder 4 is connected with the doser 2, and the doser 2 is installed at the bottom of the feeding barrel 3, and the feeding barrel 3 and the feeding barrel 3 are welded together, and the feeder 4 It includes a motor 40, a driving wheel 41, a belt 42, a driven wheel 43, a bearing 44, a moving frame 45, a lead screw 46, an outlet 47, and a housing 48. The motor 40 is connected to the driving wheel 41, and the driving wheel 41 passes The belt 42 is in transmission connection with ...

Embodiment 2

[0028] See Figure 1-3 , The present invention provides a technical solution for a bagging machine for formaldehyde adsorption particles: its structure includes a bracket 1, a meter 2, a feed barrel 3, a feeder 4, a storage box 5, an electric control box 6, a discharge port 7, Workbench 8, base 9, said base 9 is provided with workbench 8, said discharge port 7 is set above workbench 8 and connected to the bottom of storage box 5, said storage box 5 top and feeder 4 The top is connected, the bottom of the feeder 4 is connected with the doser 2, and the doser 2 is installed at the bottom of the feeding barrel 3, and the feeding barrel 3 and the feeding barrel 3 are welded together, and the feeder 4 It includes a motor 40, a driving wheel 41, a belt 42, a driven wheel 43, a bearing 44, a moving frame 45, a lead screw 46, an outlet 47, and a housing 48. The motor 40 is connected to the driving wheel 41, and the driving wheel 41 passes The belt 42 is in transmission connection with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com