Cloth inspecting machine convenient for cloth installation

A cloth inspection machine and fabric technology, applied in the field of cloth inspection machines, can solve problems such as affecting the efficiency of cloth inspection, laborious and laborious operation, affecting production efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

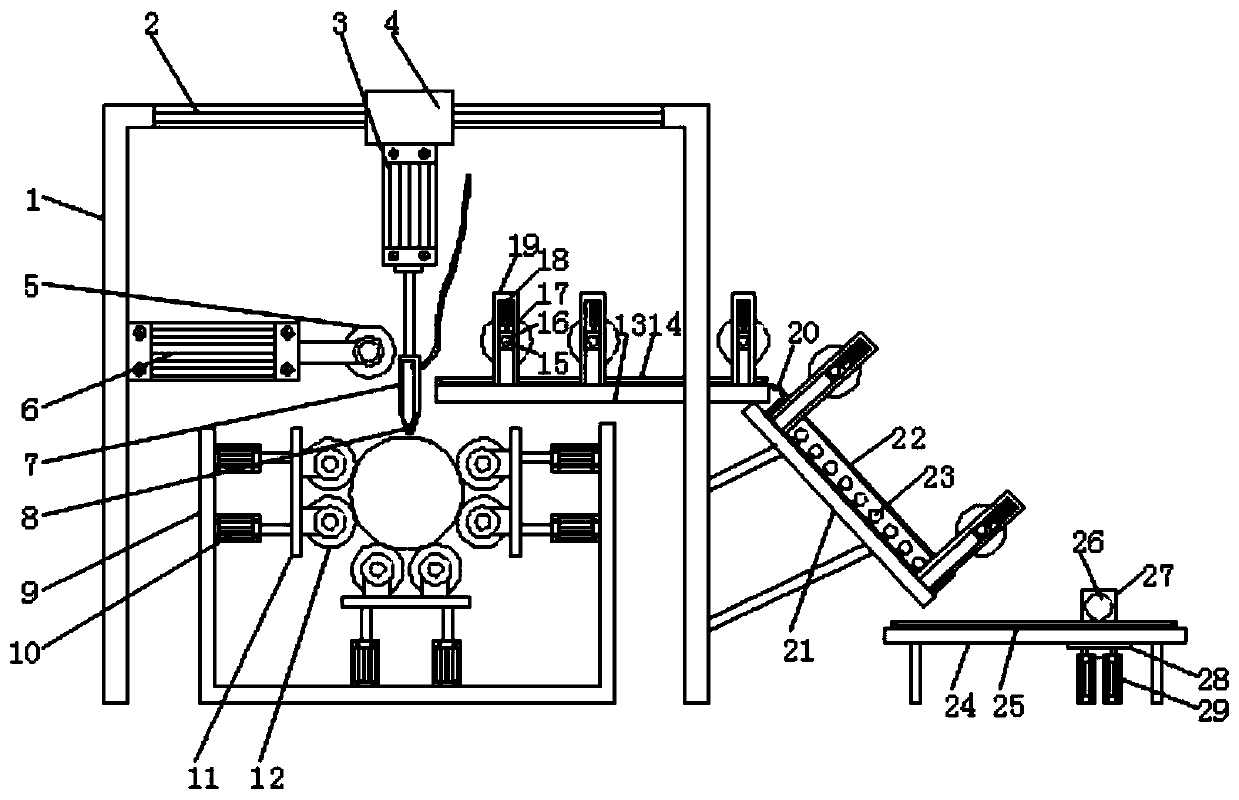

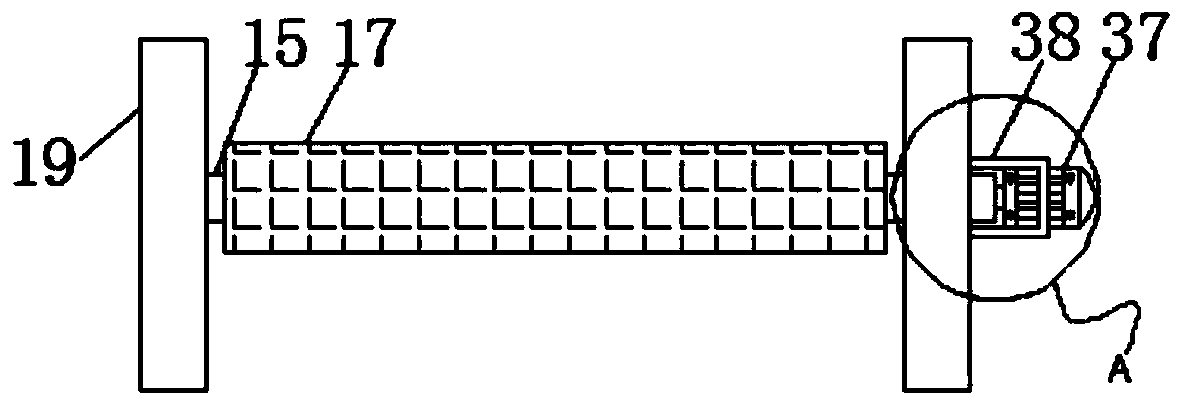

[0026] Embodiment one, with reference to figure 1 and Figure 3-4 , a cloth inspecting machine for convenient cloth installation, comprising a door frame 1 and an installation groove 9, an installation groove 9 is arranged under the door frame 1, and an installation plate 11 is connected to the inner wall of the installation groove 9 through a third cylinder 10, and the three sides of the installation plate 11 distribution, and a stabilizing roller 12 is installed on one side of the mounting plate 11, a cloth roll is placed between the stabilizing rollers 12, and the third cylinder 10 is stretched to push the stabilizing roller 12 to be squeezed and fixed to prevent the cloth from falling, and the door frame 1 top A lead screw 2 is fixedly installed on the surface, and the surface of the lead screw 2 is provided with a moving block 4, which is a common structure of the lead screw 2, and will not be repeated here, and the bottom surface of the moving block 4 is connected with a...

Embodiment 2

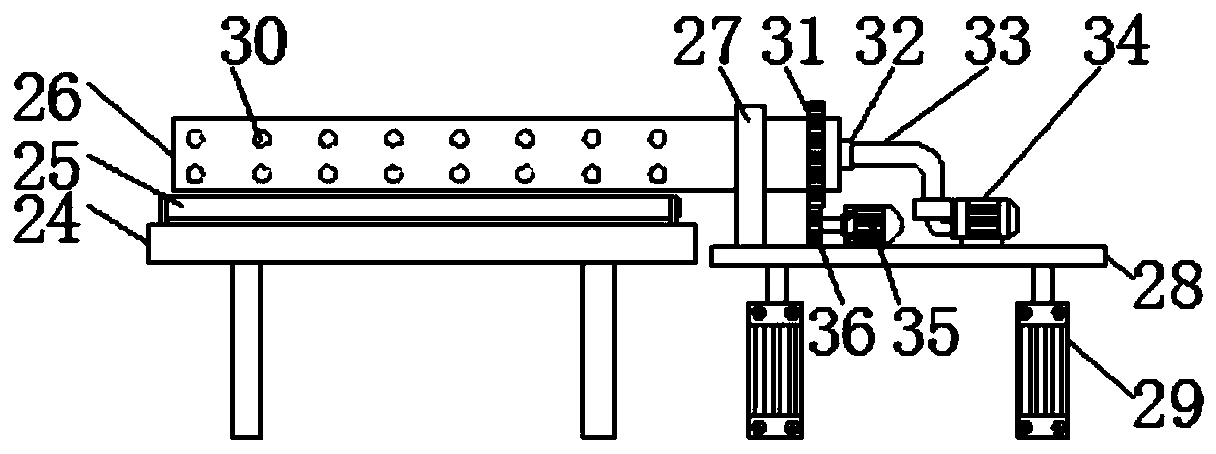

[0027] Embodiment two, refer to Figure 1-2, a third platform 24 is provided below the light box 22, and a second conveyor belt 25 is installed on the top surface of the third platform 24, and a winding roller 26 is arranged above the other end of the second conveyor belt 25, and the third platform 24 is passed through the fifth cylinder 29 is equipped with a bearing plate 28, and the top surface of the bearing plate 28 is fixedly equipped with a motor 35 and a vacuum pump 34, and one end of the rolling roller 26 is located above the bearing plate 28 and is sleeved with a gear ring 31, and the bottom surface of the gear ring 31 is engaged with a gear 36, and The gear 36 is fixedly connected with the output end of the motor 35, and the other end of the rolling roller 26 is connected with an air extraction pipe 33 through a sealed bearing 32. When the rolling roller 26 is rotating, the air extraction pipe 33 does not rotate, and the sealing bearing 32 prevents air leakage. The c...

Embodiment 3

[0028] Embodiment three, refer to Figure 1-3 The surfaces of the first press roller 5, the second press roller 17, the first conveyor belt 14 and the second conveyor belt 25 are all rough structures to prevent the cloth from slipping off, and an arc plate 20 is fixedly connected between the first platform 13 and the second platform 21, And the surface of the arc plate 20 is a smooth structure, which is convenient for the cloth to slide from the first platform 13 to the top surface of the light box 22, the first cylinder 3, the second cylinder 6, the third cylinder 10, the fourth cylinder 18, the fifth cylinder 29, and the motor 35 , the motor 37, the vacuum pump 34, the input terminals of the first conveyor belt 14 and the second conveyor belt 25 are all electrically connected to the output terminal of the control switch, because the control structure is relatively common, so it will not be repeated here.

[0029] Working principle: move the device to a suitable position, tur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com