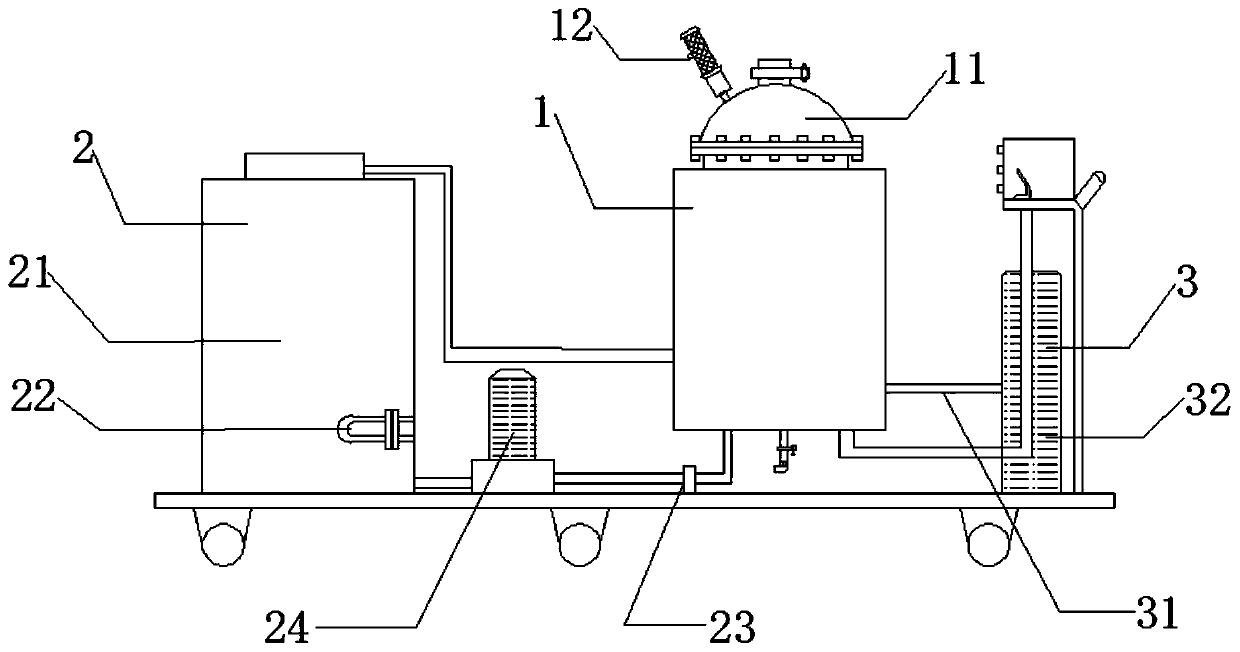

Sake fermentation device and sake making method

A fermentation device and technology for sake, applied in the field of winemaking, can solve the problems of fermentation influence, effective stirring, insufficiency, etc., and achieve the effect of accurate fermentation temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

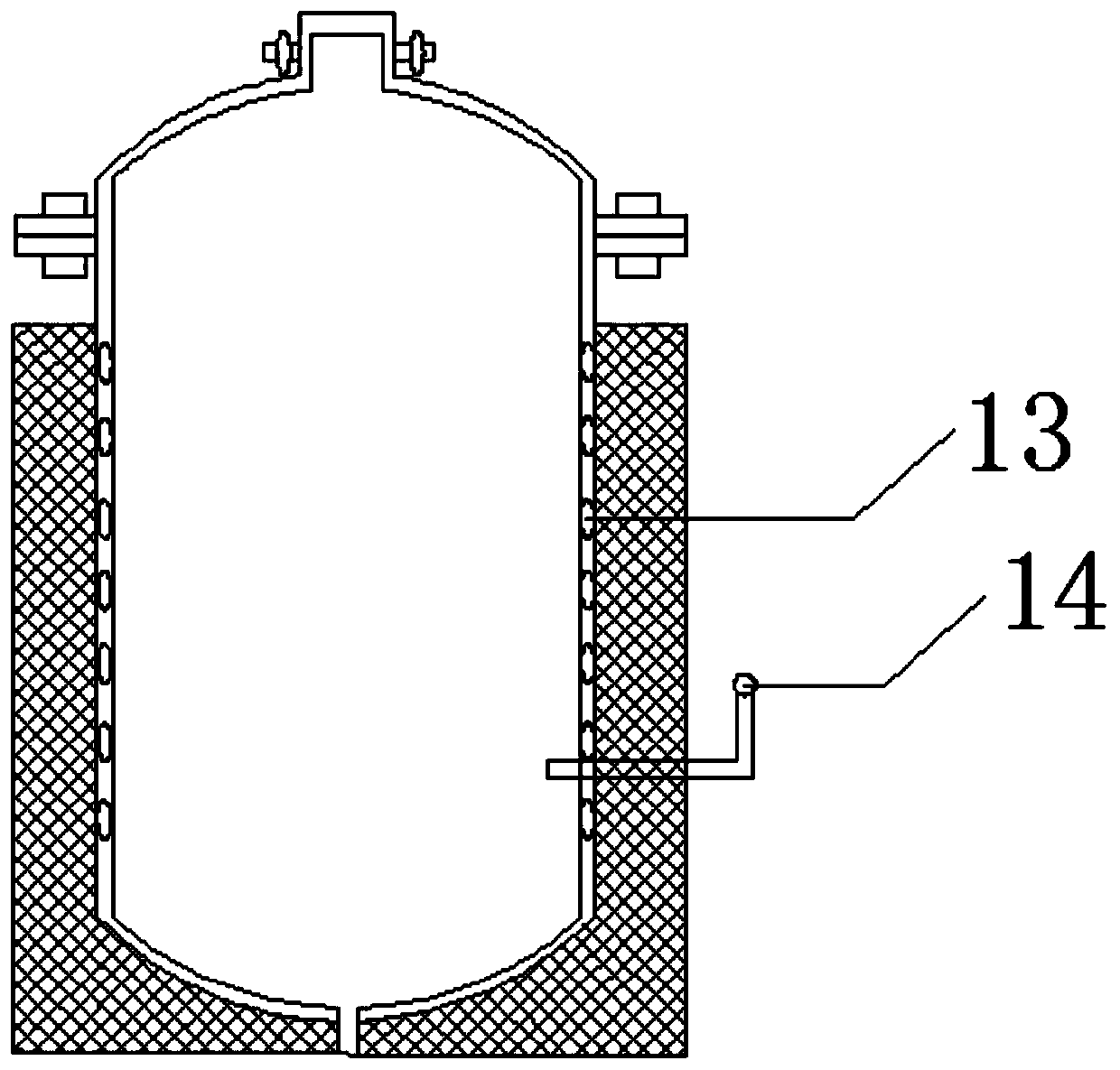

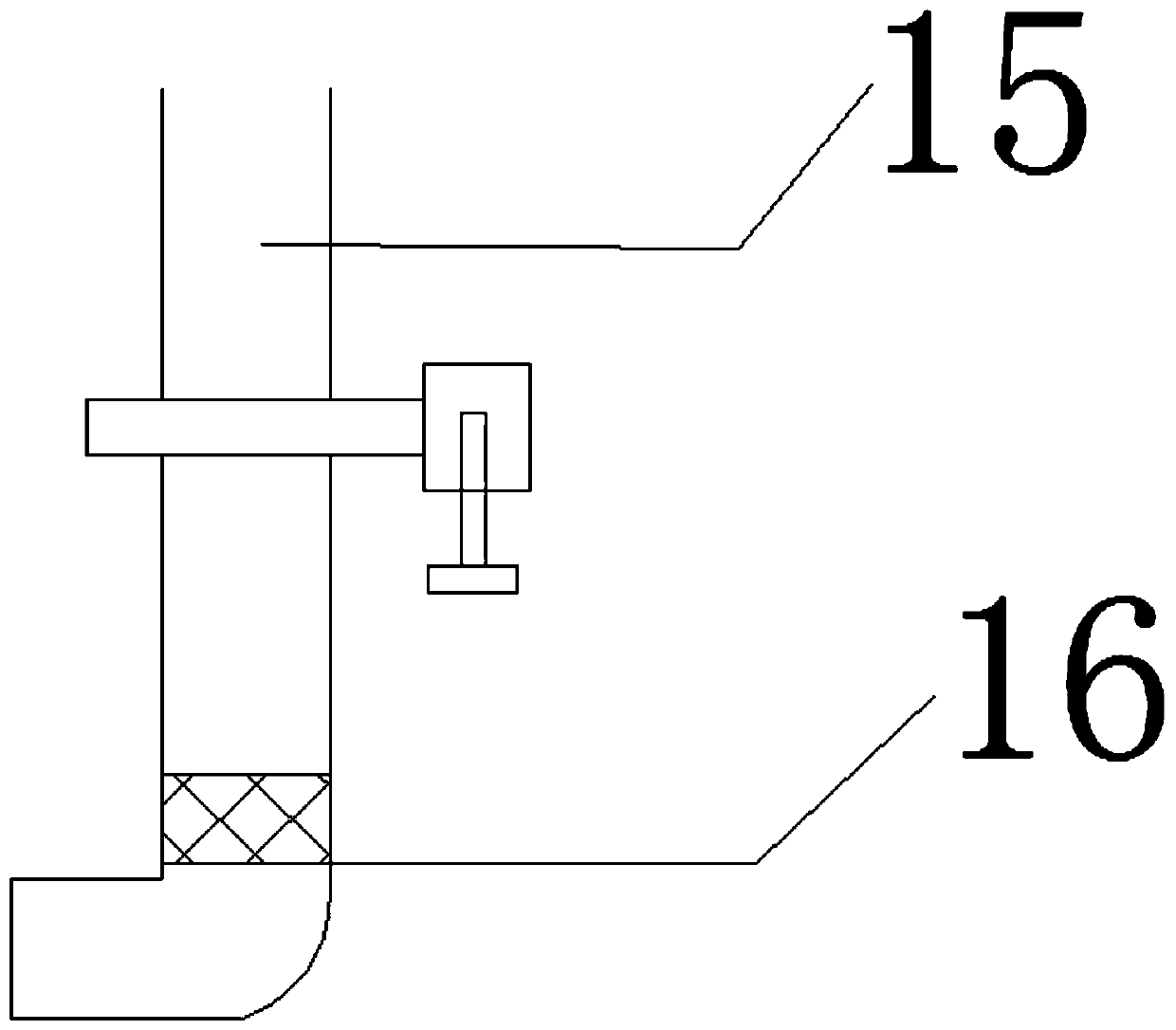

Method used

Image

Examples

Embodiment 1

[0028] The invention provides a kind of preparation method of sake, comprises the steps:

[0029] (i) Washing the rice with water for 3 times, then draining the water and then grinding to obtain rice grains with a particle size of 60 mesh;

[0030] (ii) putting the rice granules described in the step (i) into a steamer, and steaming for 30 minutes to obtain gelatinized rice;

[0031] (iii) get 50kg of the gelatinized rice described in step (ii), mix with 20kg of distiller's grains and 10kg of rice husks and stir to obtain a premix;

[0032] (iv) steaming the premix obtained in step (iii) for a second time, the cooking time is 2 hours, and the fermentation premix is obtained after completion;

[0033] (v) Mix the fermentation premix obtained in step (iv) with rice koji, the weight ratio of the fermentation premix to rice koji is 100:0.1, and ferment in a sake fermentation device at 12°C for 20 days, and end After filtering and separating, the clear liquid is taken to obtain...

Embodiment 2

[0035] The invention provides a kind of preparation method of sake, comprises the steps:

[0036] (i) Washing the rice with water for 4 times, then draining the water and then grinding to obtain rice grains with a particle size of 80 meshes;

[0037] (ii) putting the rice granules described in the step (i) into a steamer, steaming and cooking for 40 minutes to obtain gelatinized rice;

[0038] (iii) get 80kg of the gelatinized rice described in step (ii), mix and stir with 30kg of distiller's grains and 20kg of rice husk to obtain a premix;

[0039] (iv) steaming the premix obtained in step (iii) for a second time, the cooking time is 3 hours, and the fermentation premix is obtained after completion;

[0040] (v) Mix the fermentation premix obtained in step (iv) with rice koji, the weight ratio of the fermentation premix to rice koji is 100:0.2, and ferment in a sake fermentation device at 16°C for 25 days, and end After filtering and separating, the clear liquid is taken ...

Embodiment 3

[0042] The invention provides a kind of preparation method of sake, comprises the steps:

[0043] (i) Washing the rice with water for 4 times, then draining the water and then grinding it to obtain rice grains with a particle size of 70 meshes;

[0044] (ii) putting the rice granules described in the step (i) into a steamer, and steaming for 35 minutes to obtain gelatinized rice;

[0045] (iii) get 65kg of the gelatinized rice described in step (ii) and mix and stir with 25kg distiller's grains and 15kg rice husk to obtain a premix;

[0046] (iv) steaming the premix obtained in step (iii) for a second time, the cooking time is 3 hours, and the fermentation premix is obtained after completion;

[0047] (v) Mix the fermented premix obtained in step (iv) with rice koji, the weight ratio of the fermented premix and rice koji is 100:0.15, and ferment in a sake fermentation device at 14°C for 22 days, and end After filtering and separating, the clear liquid is taken to obtain sa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com