Textile raw material transmission ironing equipment

A technology of ironing equipment and raw materials, applied in the field of textile processing, can solve the problems of lack of thread guidance, lack of dust removal measures for each thread, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

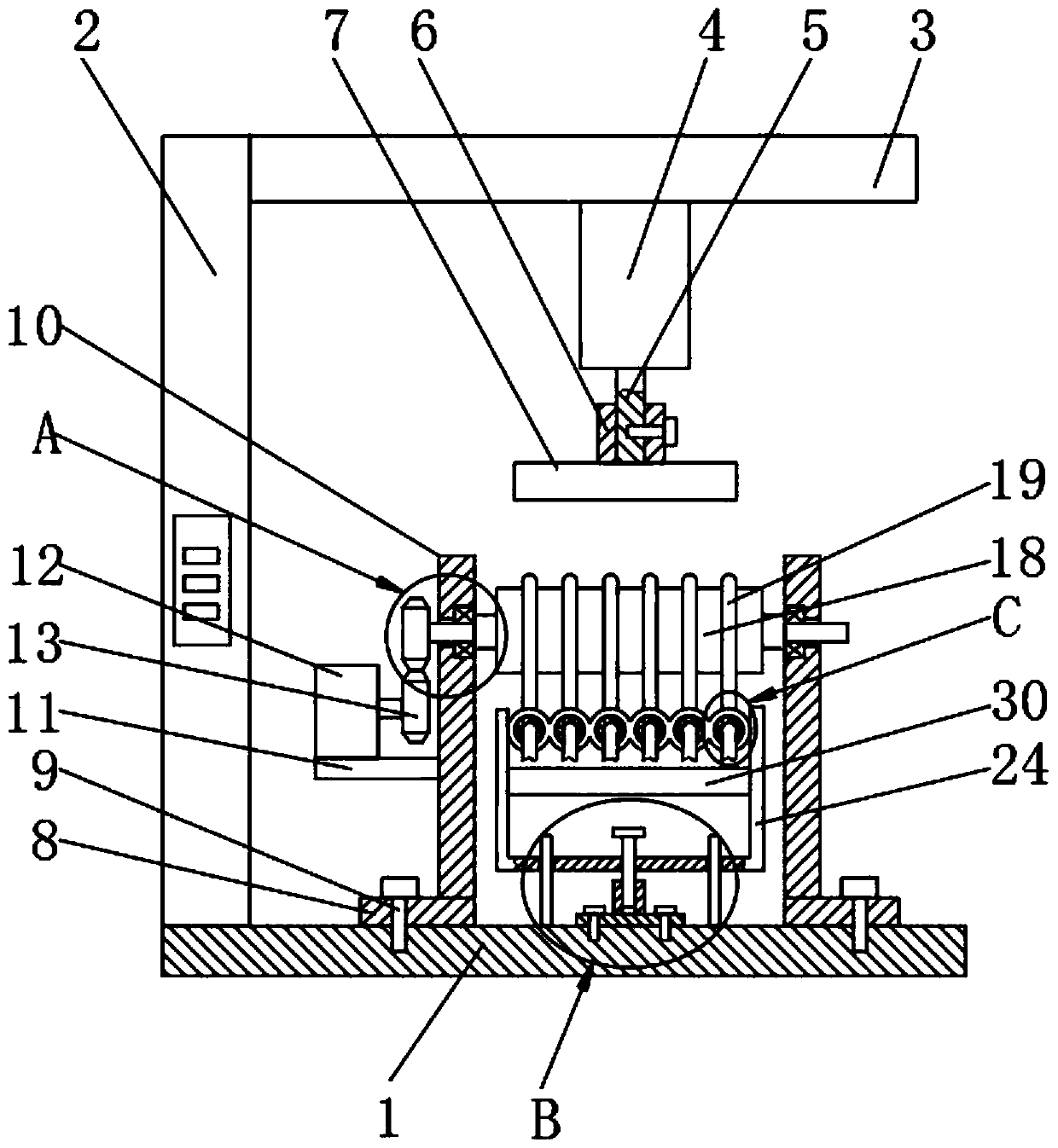

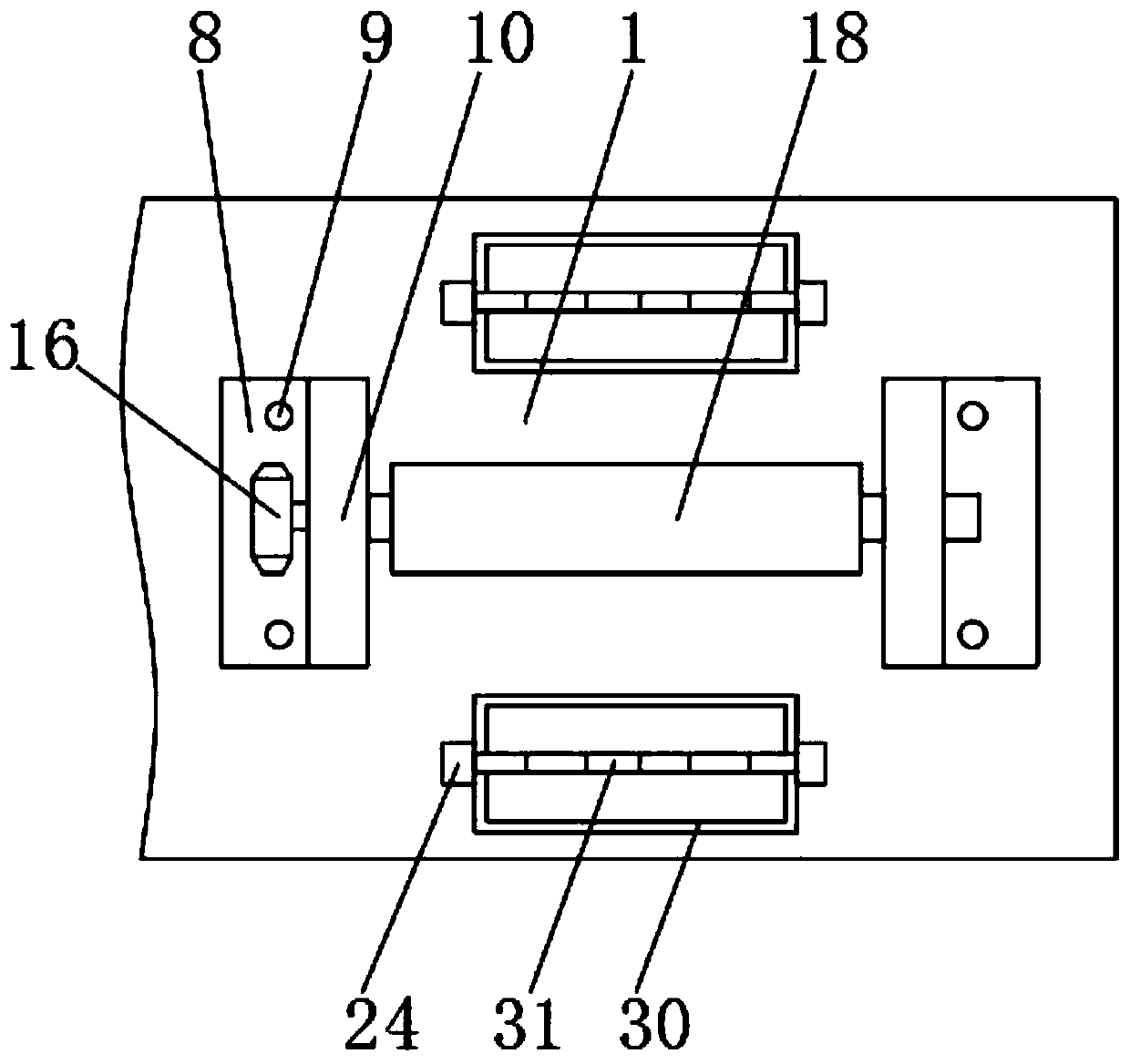

[0027] see Figure 1-6 , a textile raw material transmission ironing equipment, including a base 1, the upper end of the base 1 is welded with a support column 2, the upper end of the support column 2 is welded with a beam 3, and the lower end of the beam 3 is fixedly installed with a cylinder 4, the cylinder 4 is SC series standard The cylinder belongs to the prior art and is equipped with a control switch for controlling the cylinder 4. The lower end of the cylinder rod 5 of the cylinder 4 is provided with a connecting sleeve 6 through screws, and the lower end of the connecting sleeve 6 is fixedly equipped with an ironing board 7. It belongs to the prior art, and the thread 19 can be ironed. The upper end of the base 1 is fixed with a support seat 8, and the upper end of the support seat 8 is welded with a support frame 10;

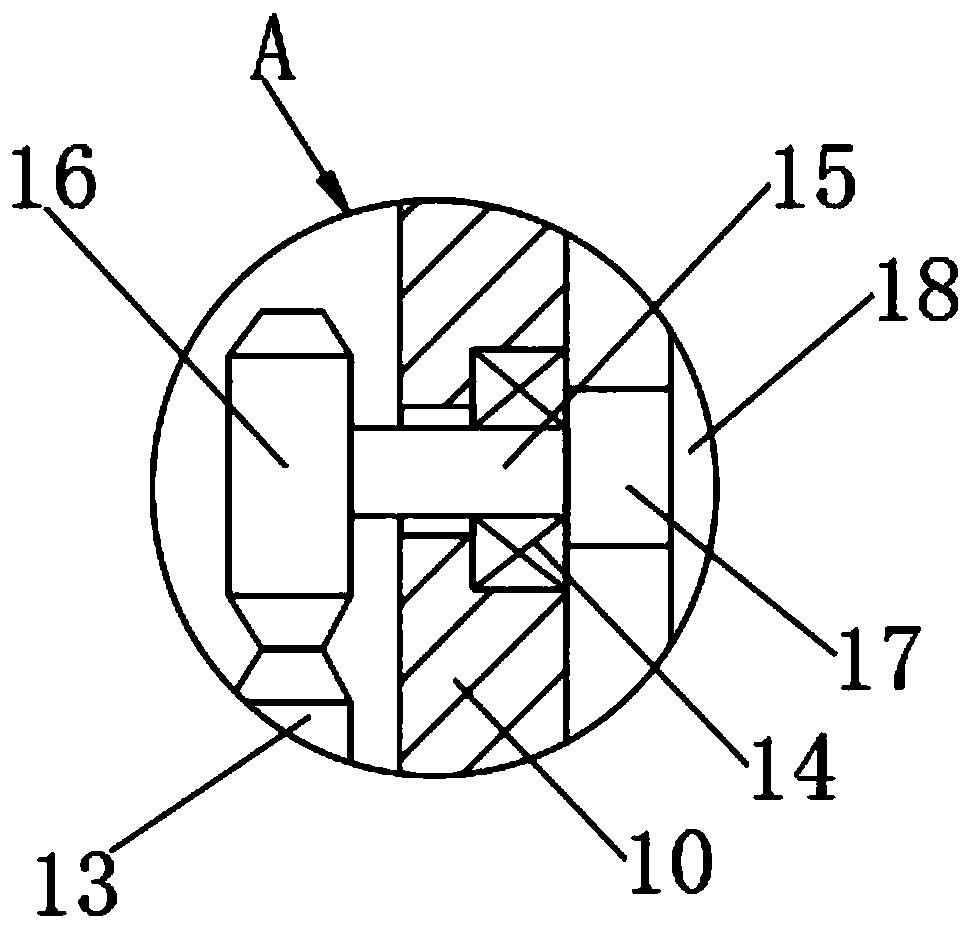

[0028] The left end of the support frame 10 is welded with a support plate 11, and the upper end of the support plate 11 is fixedly equipped with a mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com