Electromagnetic needle lifting unit applied to electronic jacquard machine, electromagnetic needle lifting module

An electronic jacquard and electromagnetic technology, applied in jacquard machines, textiles, textiles and papermaking, etc., can solve the problems of impact wear, manufacturing difficulties, fatigue fracture, etc., to eliminate fatigue wear and fracture, low sealing requirements, The effect of low part wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

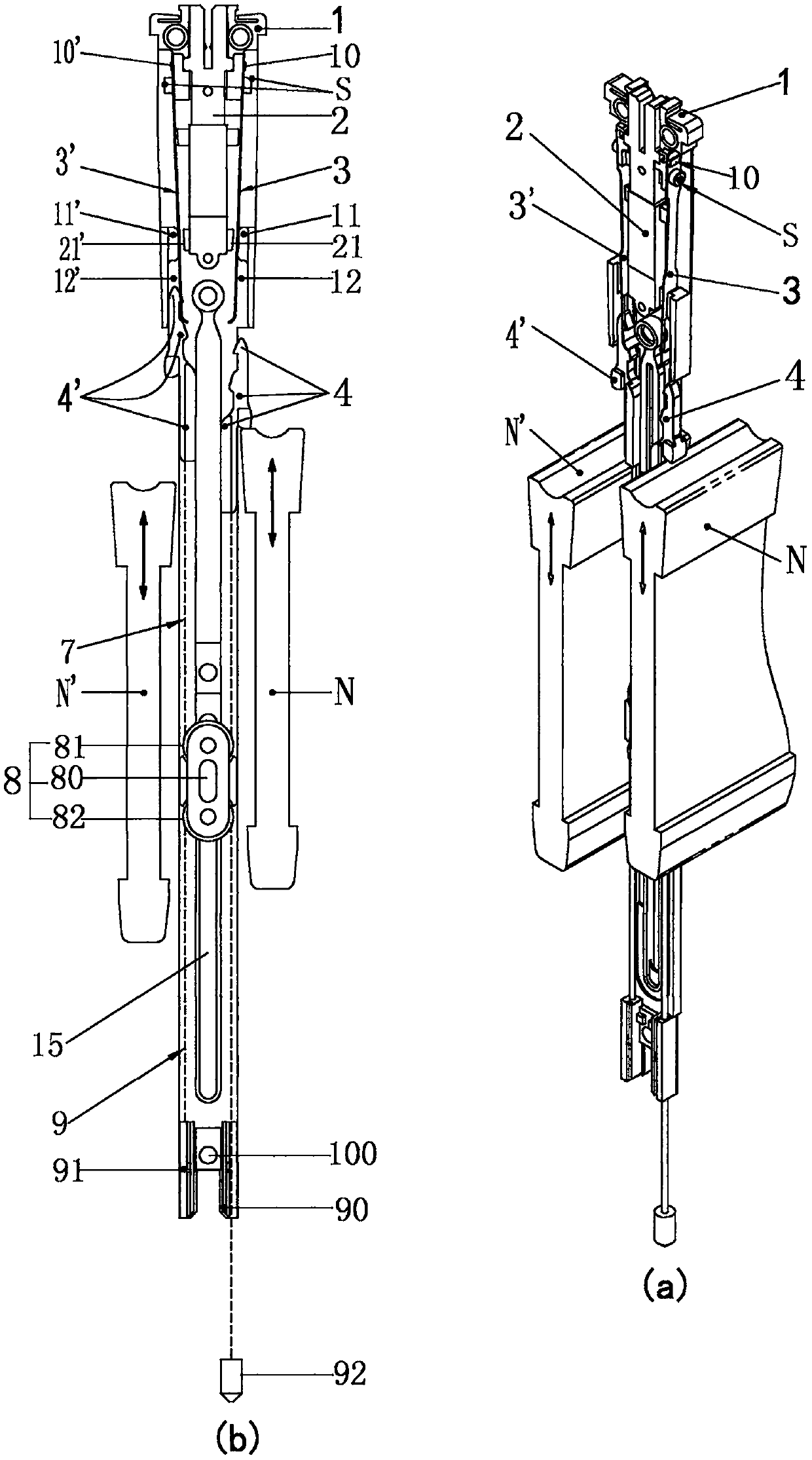

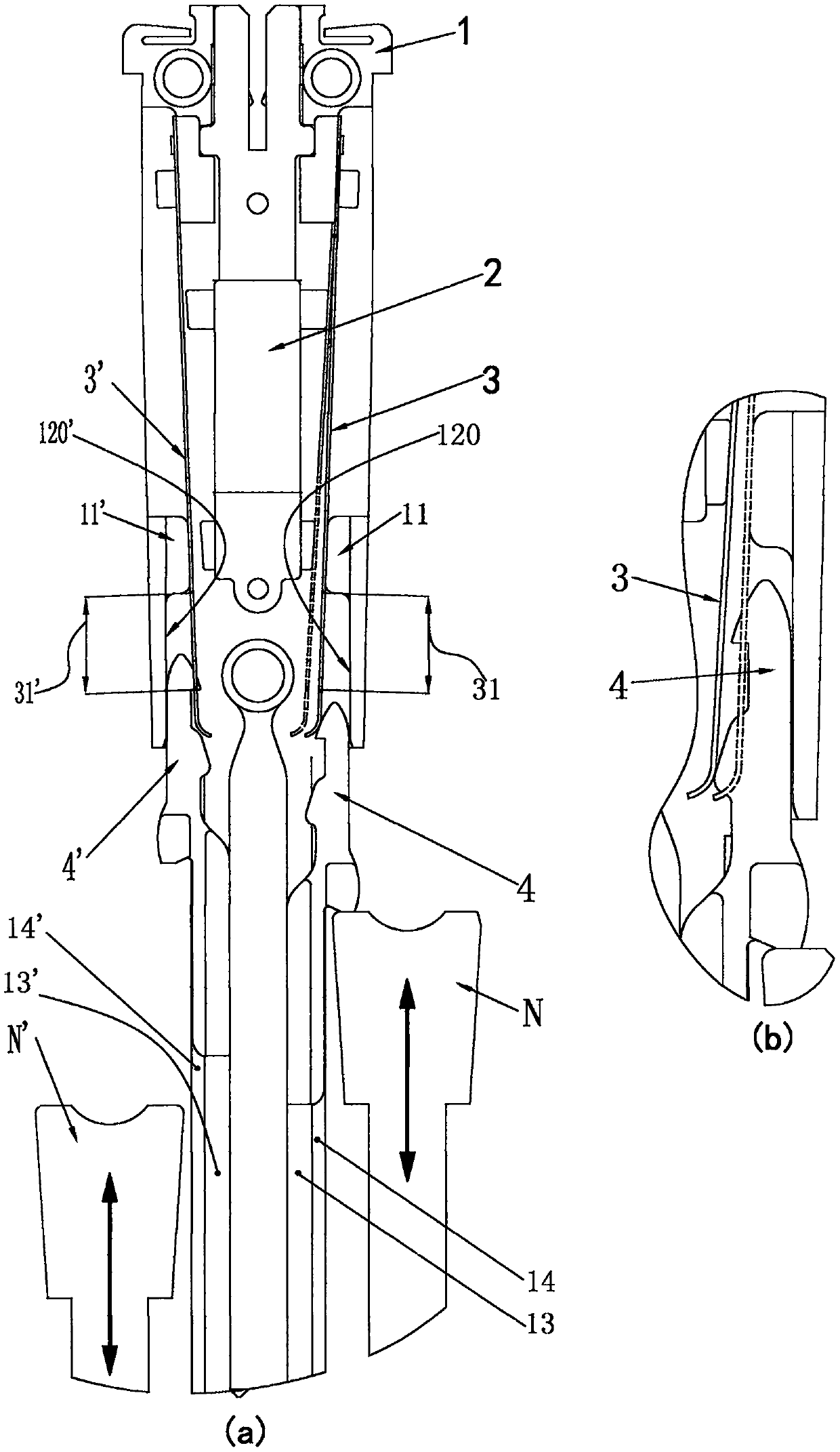

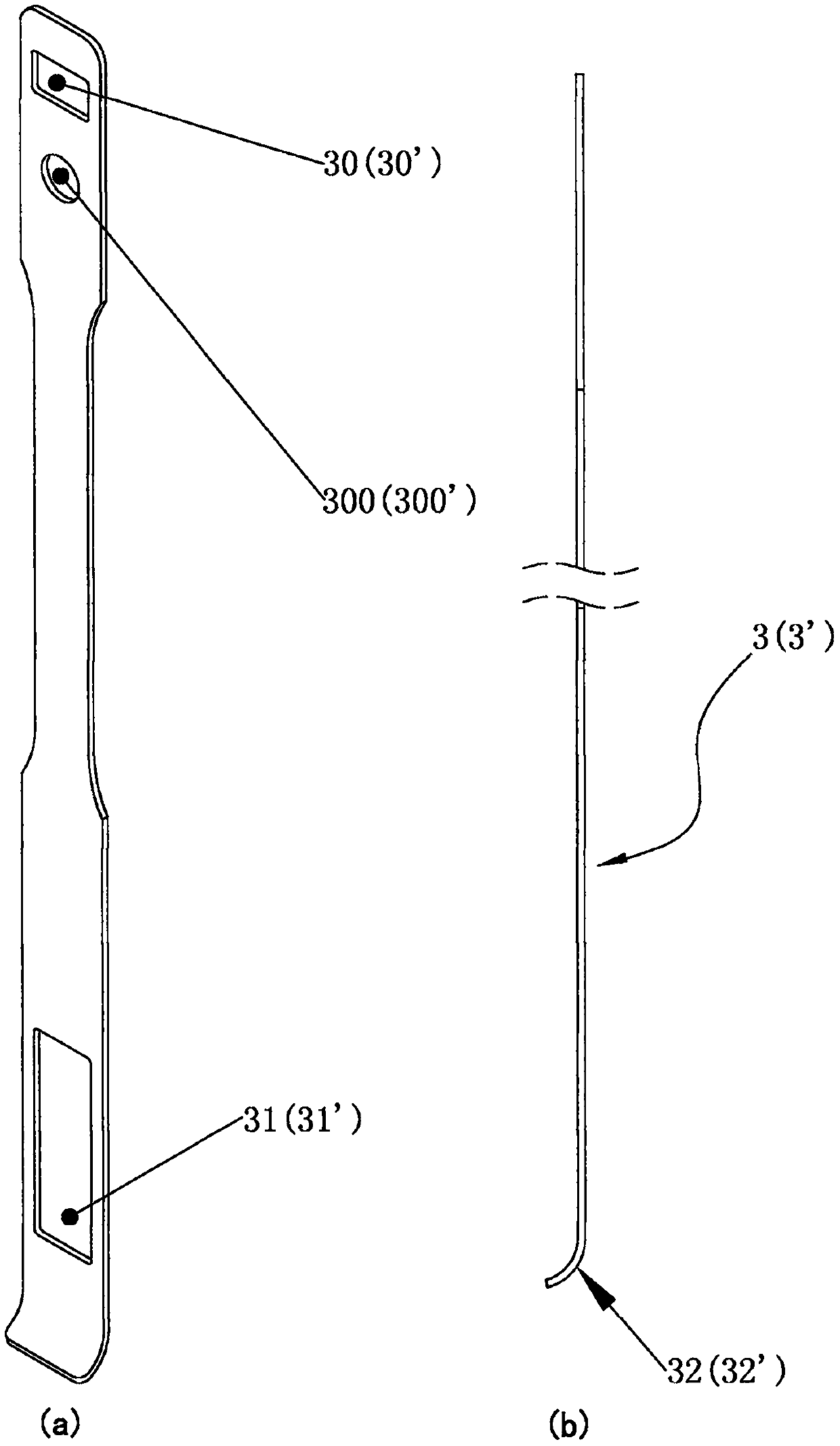

[0037] Please refer to the attached Figure 1~6 As shown, the electromagnetic needle lifting unit used for electronic jacquard machines is mainly composed of a base plate 1, an electromagnet 2 fixed on the base plate 1, a sliding hook 4, a sliding hook 4' and a rope-connected pulley block. The sliding hook 4 includes The hook body part 5 and the rod body part 6, the sliding hook 4' includes the hook body part 5' and the rod body part 6', the head end of the hook body part 5 forms a hook head 51, and the head end of the hook body part 5' forms a hook head 51', the bottom surface 5b of the hook body part 5 and the bottom surface 5b' of the hook body part 5' are respectively used as thrust surfaces for the lifting knives N and N' that move up and down alternately, and the rod body parts 6 and 6' slide vertically respectively It is installed on the base plate 1 , and the hook head 51 corresponds to the hook head 51 ′.

[0038] Wherein, the rope-connected pulley block is a known s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com