Tow printing and dyeing device based on textile processing

A technology of tow and printing and dyeing box, applied in the field of textile processing, which can solve the problems of difficult separation of cotton tow, short time, color difference between edges, etc., and achieve the effects of uniform spreading speed and angle, uniform coloring, and wide range of pad dyeing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

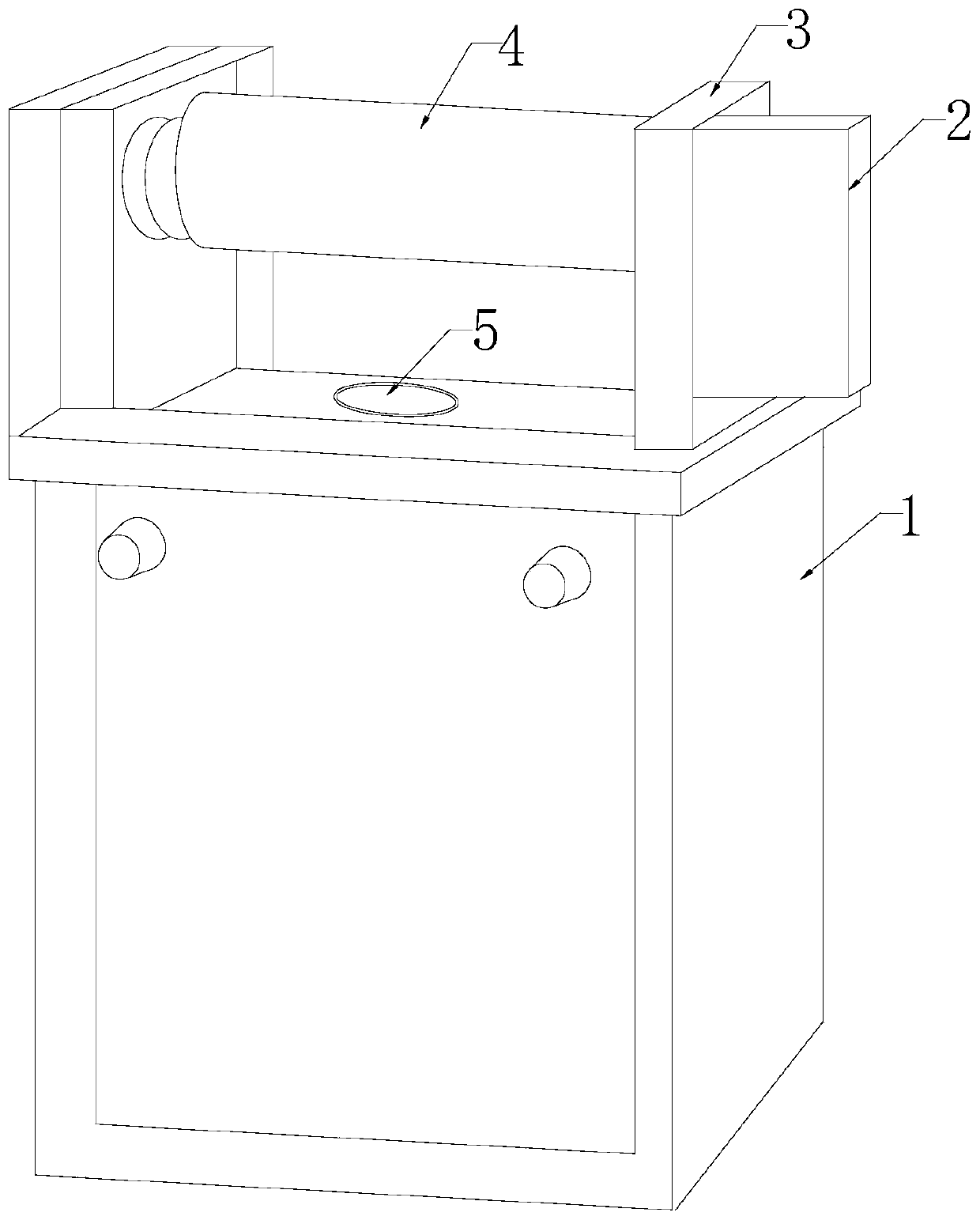

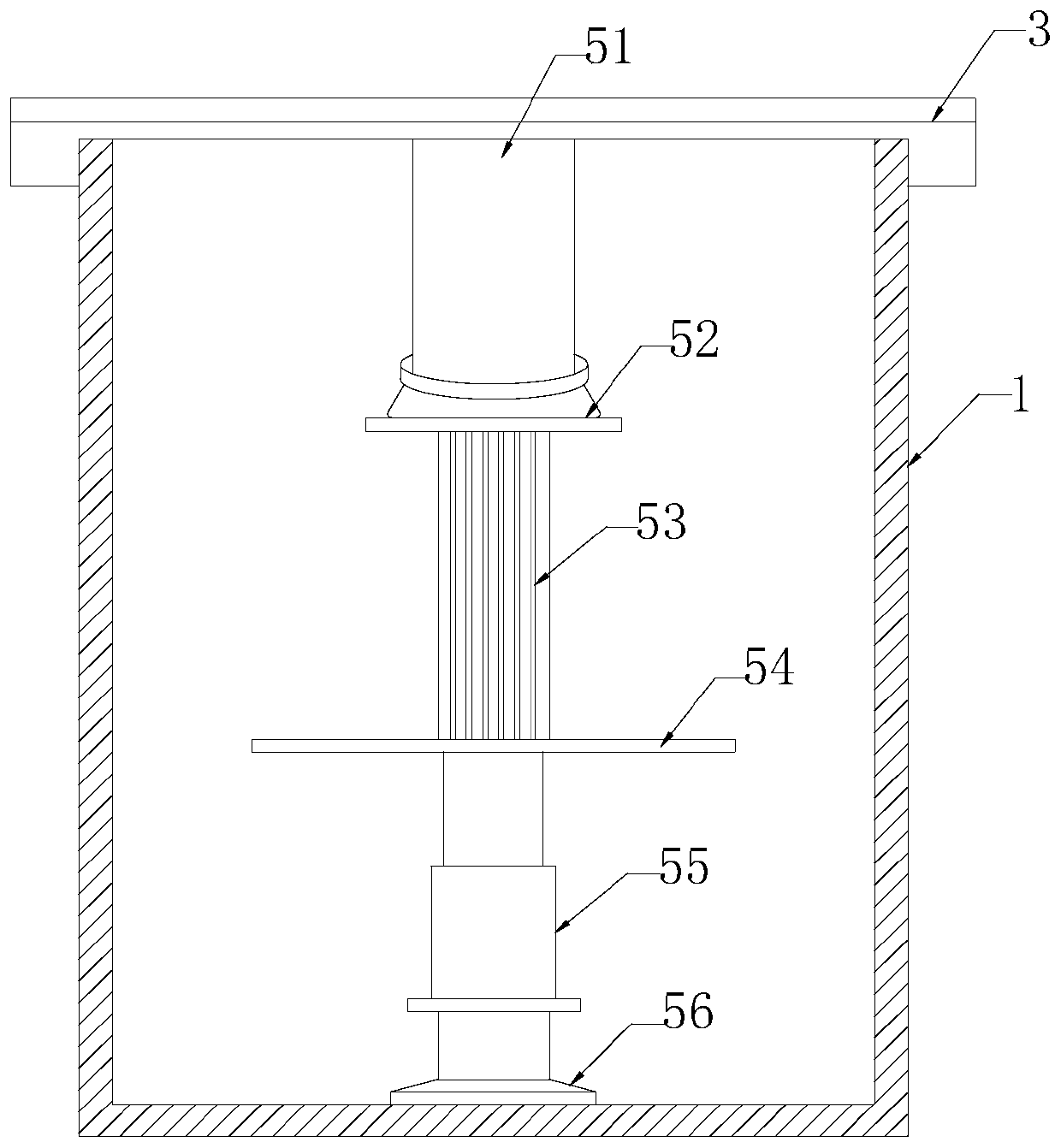

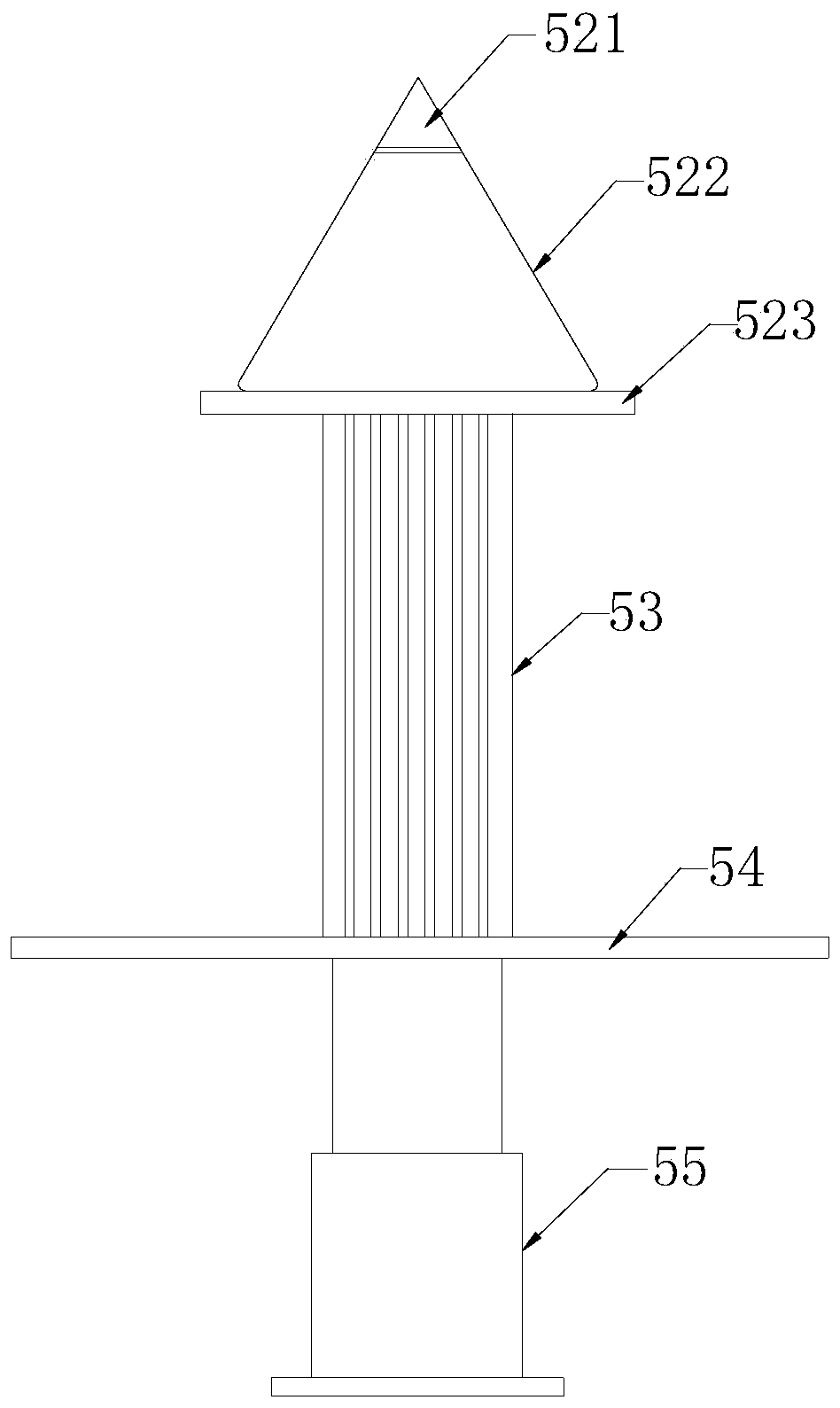

[0025] like Figure 1-Figure 5 As shown, the present invention provides a tow printing and dyeing device based on textile processing, and its structure includes a printing and dyeing box 1, an electric control box 2, a support 3, a drum 4, and a tow discharge port 5, and the printing and dyeing box 1 is welded with a bracket 3. A tow outlet 5 is provided between the support 3 and the printing and dyeing box 1, an electric control box 2 is installed on the support 3, and a movable part mechanically connected to the drum 4 is provided between the two opposite supports 3. The tow outlet 5 is located inside the printing and dyeing box 1 and is provided with a feeding cylinder 51, a splitting plate 52, an expansion unit 53, a slideway 54, a telescopic bottom shaft 55, and a supporting base 56. The splitting The top of the plate 52 passes through the inside of the feeding cylinder 51, and the bottom of the splitting plate 52 is fixed with an expansion part 53, and the expansion part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com