A fitted push plate two-way artificial wave-making device and method

A push plate and wave-making technology, which is applied in the field of fitted push plate two-way artificial wave-making device, can solve the problem of too large source engine capacity and only one wave can be created

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

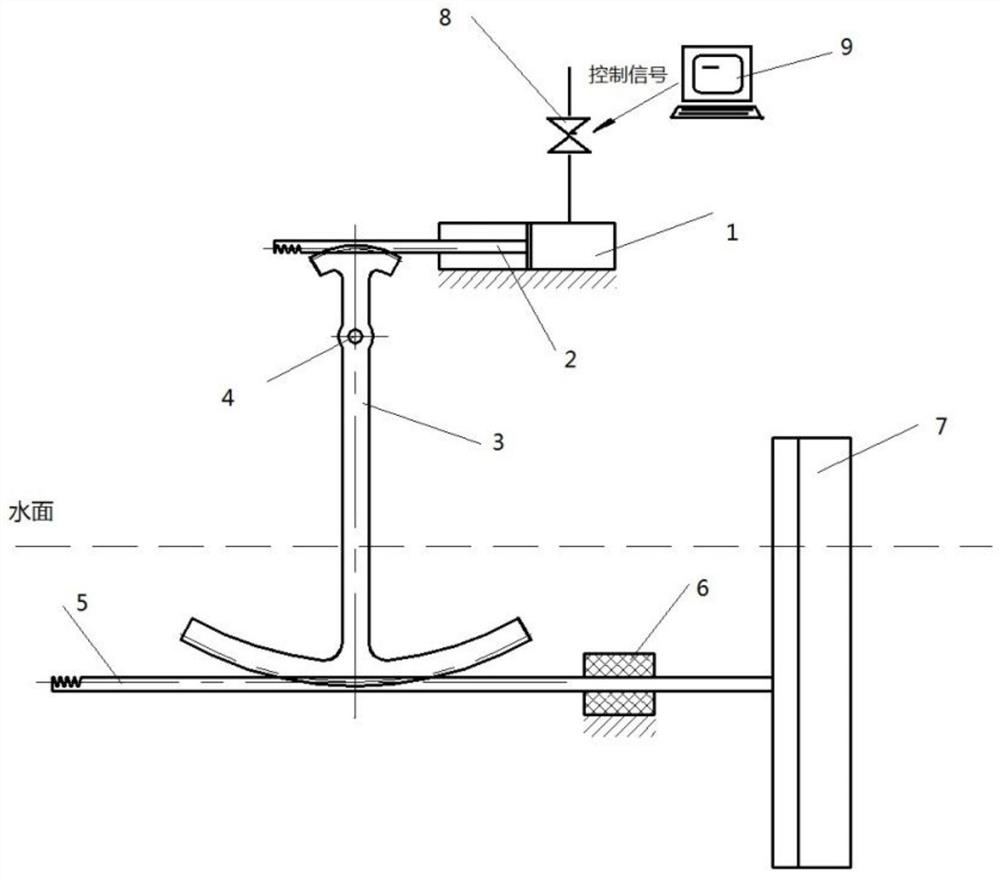

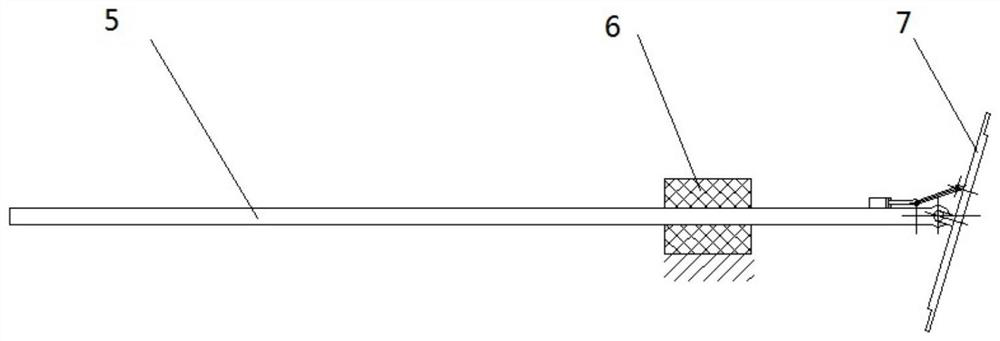

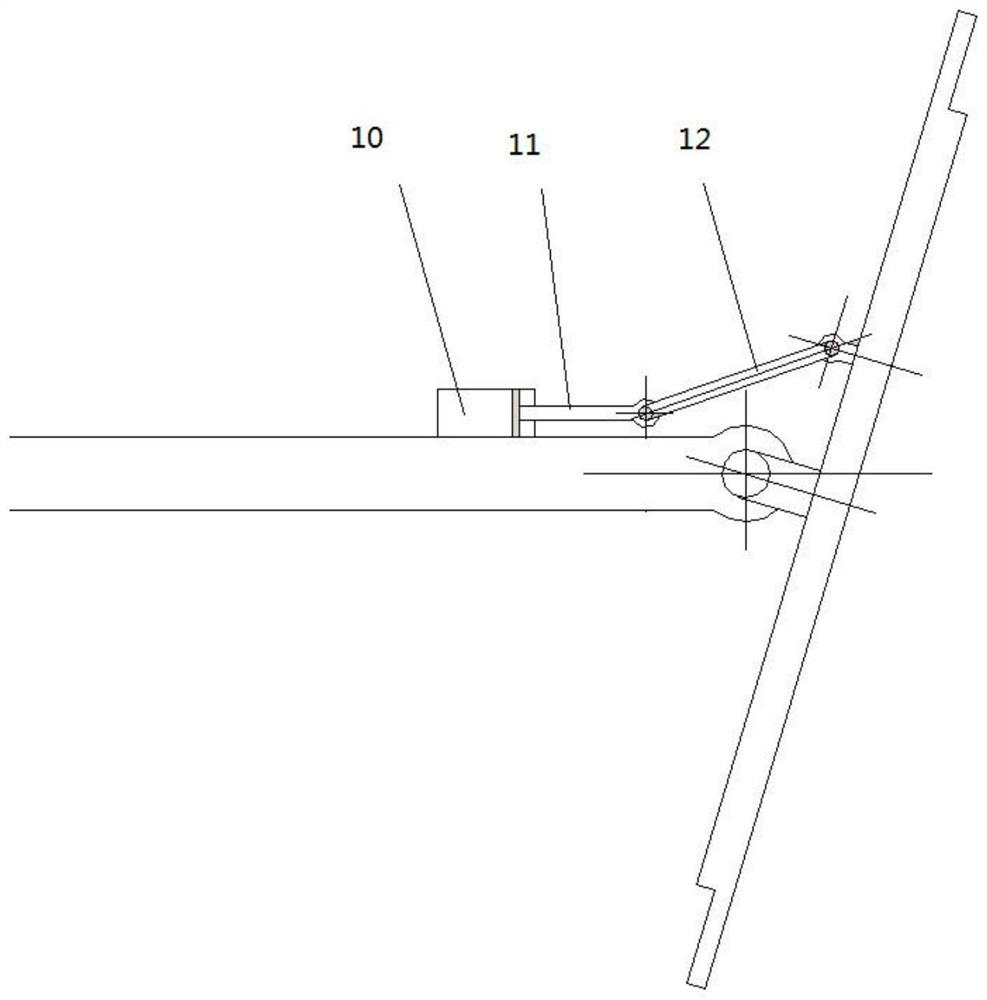

[0029] The invention proposes a fitted artificial wave-making device. The vertical parts or all of the push plates arranged in a continuous line are immersed in the water pool. The push plates can be made of metal or non-metal structural materials. If they are immersed in water for a long time, they need to be treated with anticorrosion or the material itself has corrosion resistance. Each push plate is hinged to one end of the horizontally installed push rod, and the hinge axis is vertical, that is, the push plate can swing around the vertical axis relative to the push rod, and the swing angle is determined by the attitude adjustment hydraulic cylinder installed on the push rod. , attitude adjustment push rod and connecting rod to control. The other end of the push rod is processed into a rack, and the rack meshes with the sector gear at the high-speed end of the shift lever, and the sector gear at the low-speed end of the shift lever meshes with the rack portion on the drive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com