Drum brake and vehicle brake system

A drum brake and brake shoe technology, applied in the field of vehicles, can solve problems such as high maintenance costs, vehicle brake deviation, and impact on driving safety, so as to reduce maintenance costs, prevent dragging, and ensure driving safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

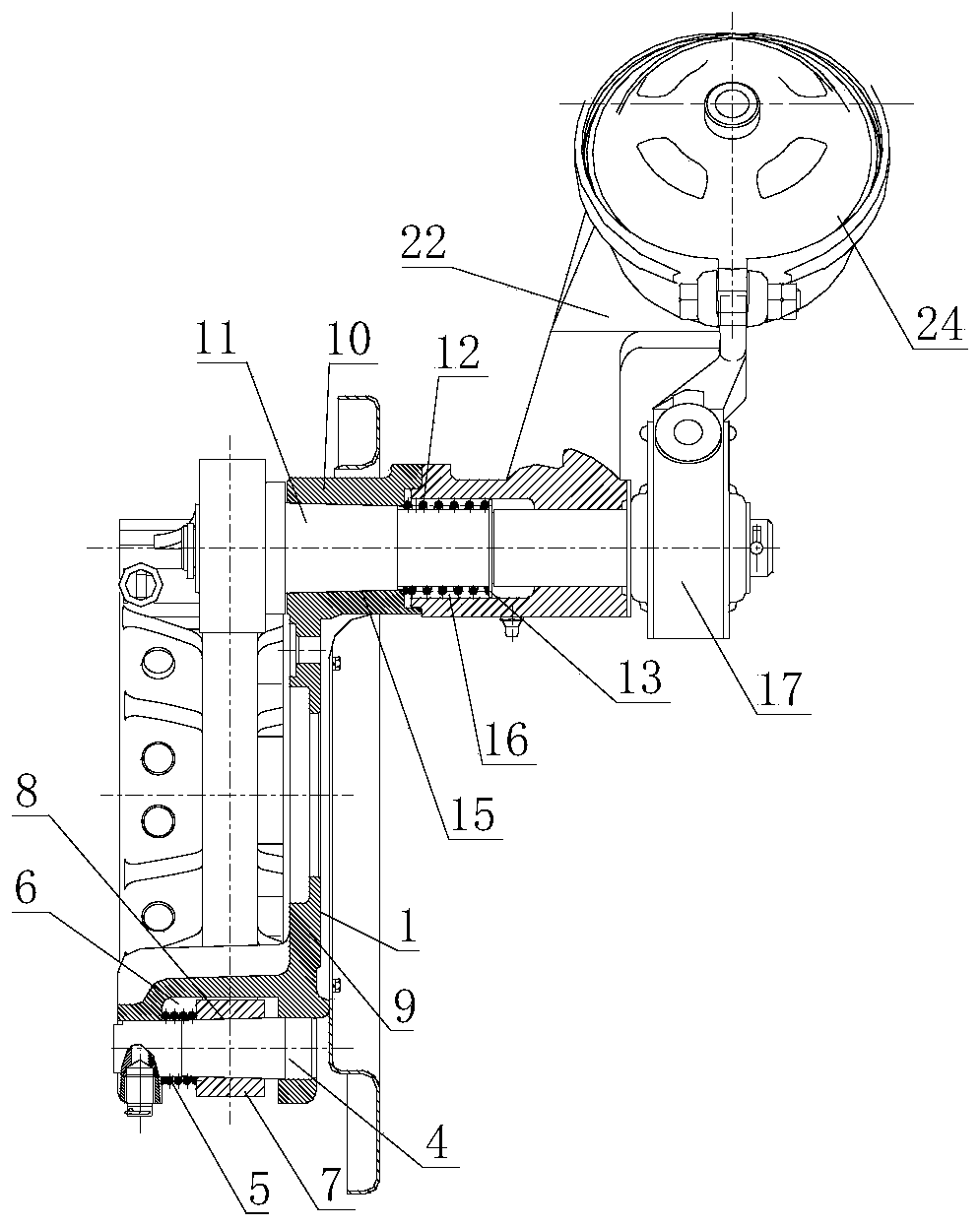

[0037] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

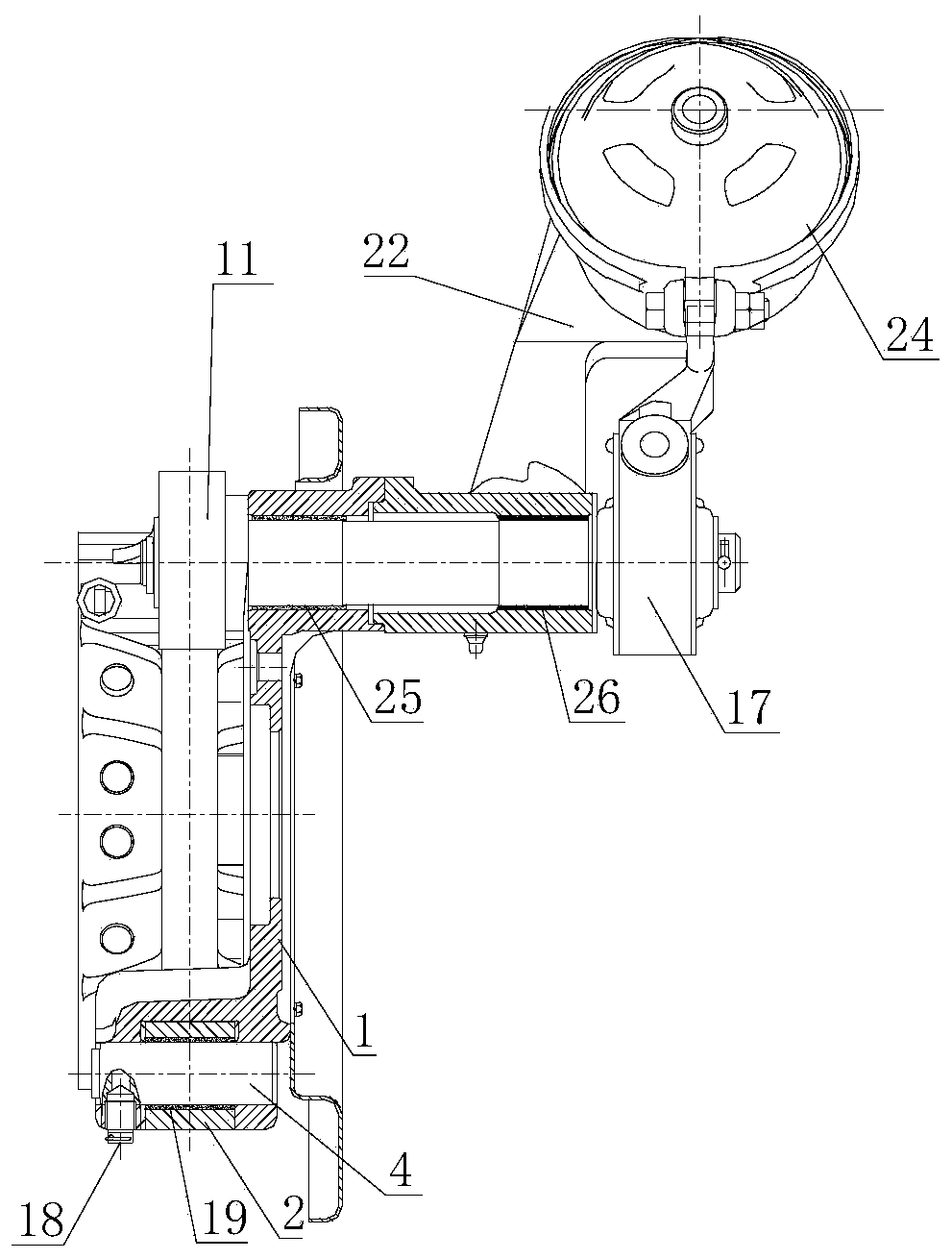

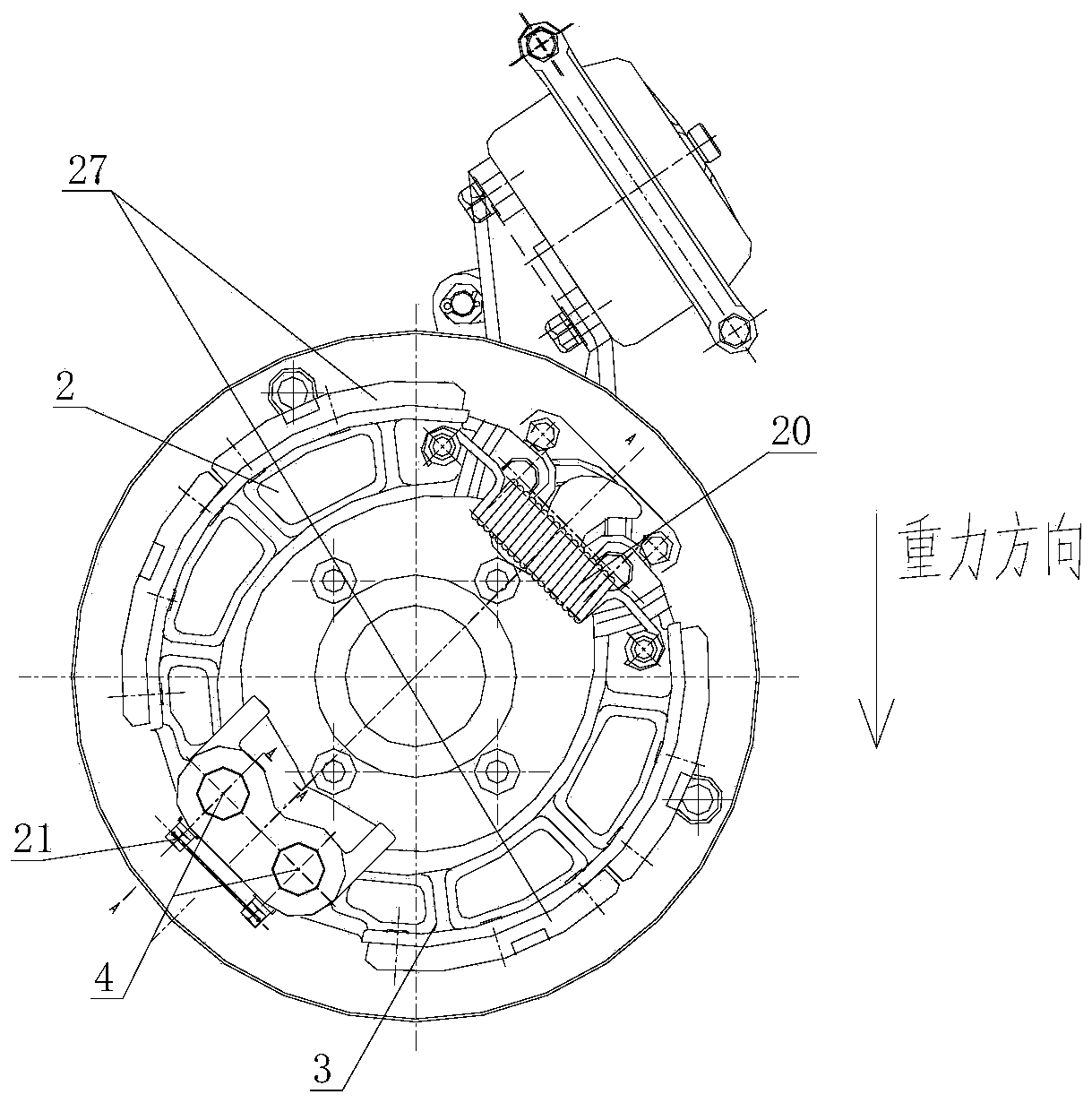

[0038] combine Figure 3-Figure 8 According to one aspect of the present invention, a drum brake is provided, comprising:

[0039] Brake base 1;

[0040] A brake shoe assembly, the brake shoe assembly is mounted on the brake base plate 1 through a brake shoe pin 4, and the brake shoe pin 4 is set to gradually increase in diameter along the axial direction; and

[0041] The first elastic member 5 is configured to provide a biasing force to the brake shoe assembly in a direction in which the diameter of the brake shoe pin 4 increases.

[0042]Through the above-mentioned technical solution, the drum brake of the present invention sets the brake shoe pin shaft to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com