Clamping belt for installation component

A technology for components, tubular components, applied in the field of clamping straps for mounting components, to achieve the effects of reliable operation, easy assembly process, and simple components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

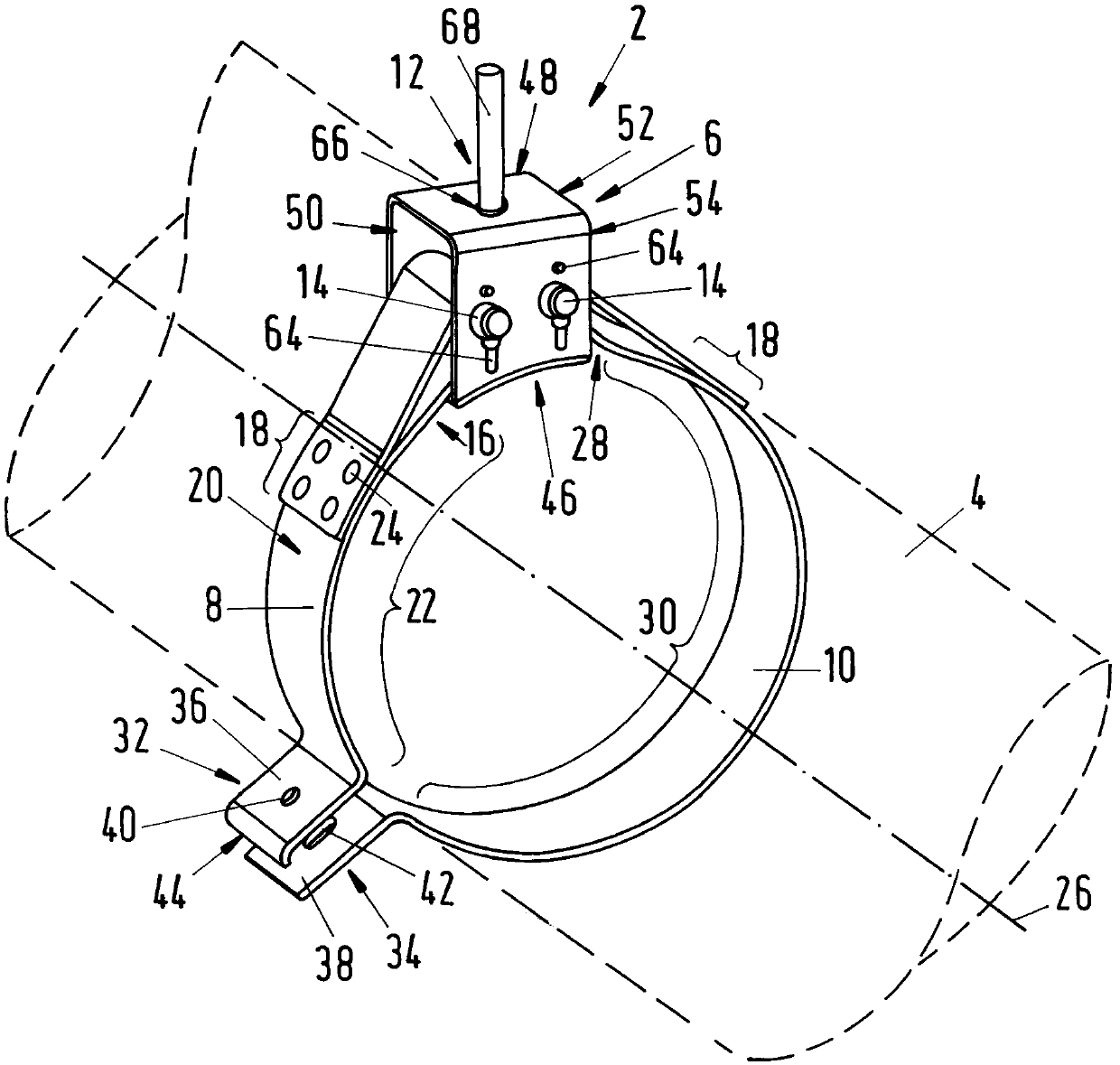

[0029] figure 1 A device 2 for holding a tubular member 4 on a vehicle (not shown) is depicted. It is here indicated that the term "tubular" does not necessarily relate to a part that is entirely tubular. Instead, said part to be held may simply consist of a tubular or cylindrical part, which can be surrounded by said device 2 according to the invention.

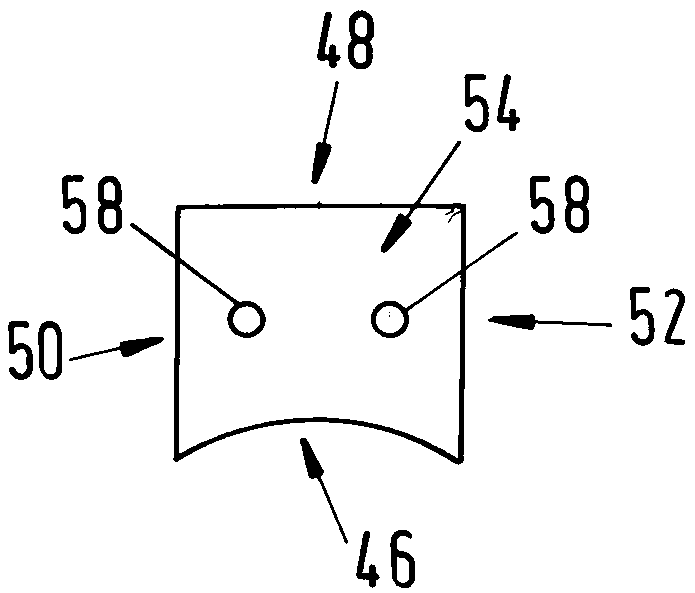

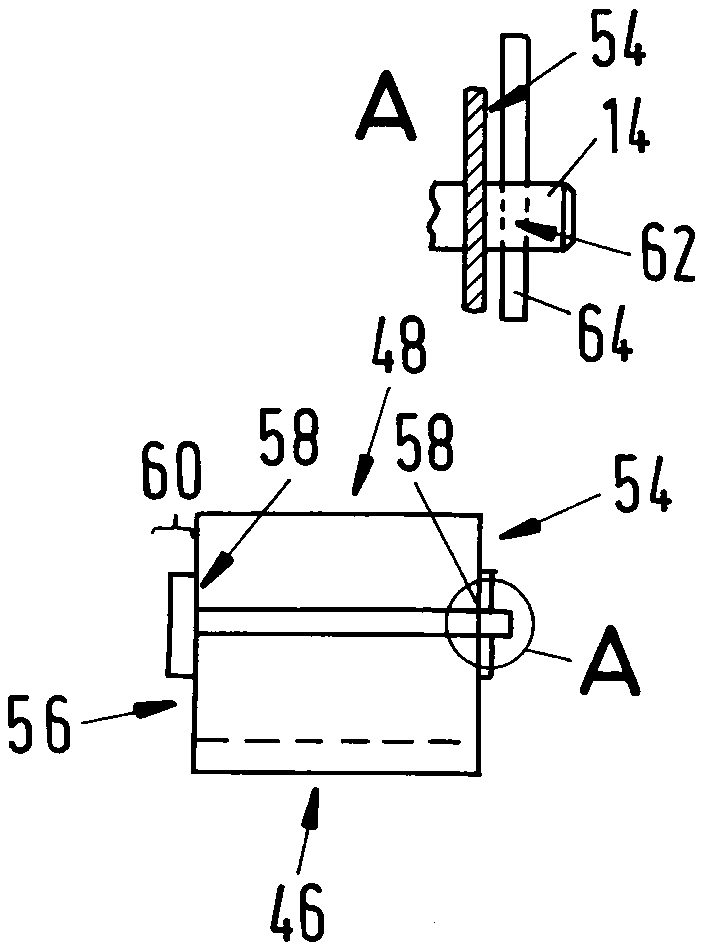

[0030] Said device 2 comprises a frame 6 , a first strip-shaped part 8 , a second strip-shaped part 10 , a holding device 12 and two trunnions 14 . Both strip parts 8 and 10 are based on a strip-shaped workpiece, preferably made of metallic material. The first strap 8 comprises a first loop 16 formed by folding or bending the end of the first strap through approximately 180° so that an end section 18 lies flush in a first clamping On an outer radial surface 20 of portion 22 , said first clamping portion is bent to conform to the shape of said component 4 . The end section 18 is rigidly connected to the clamping part 22 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com