A kind of lampblack odor purification treatment equipment

A purification treatment and oil fume technology, applied in the direction of oil fume removal, lighting and heating equipment, household stoves/stoves, etc., can solve problems such as poor smoke exhaust, increased resistance, pungent nose, etc., to achieve stable power connection, stable connection, and improved The effect of collecting effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

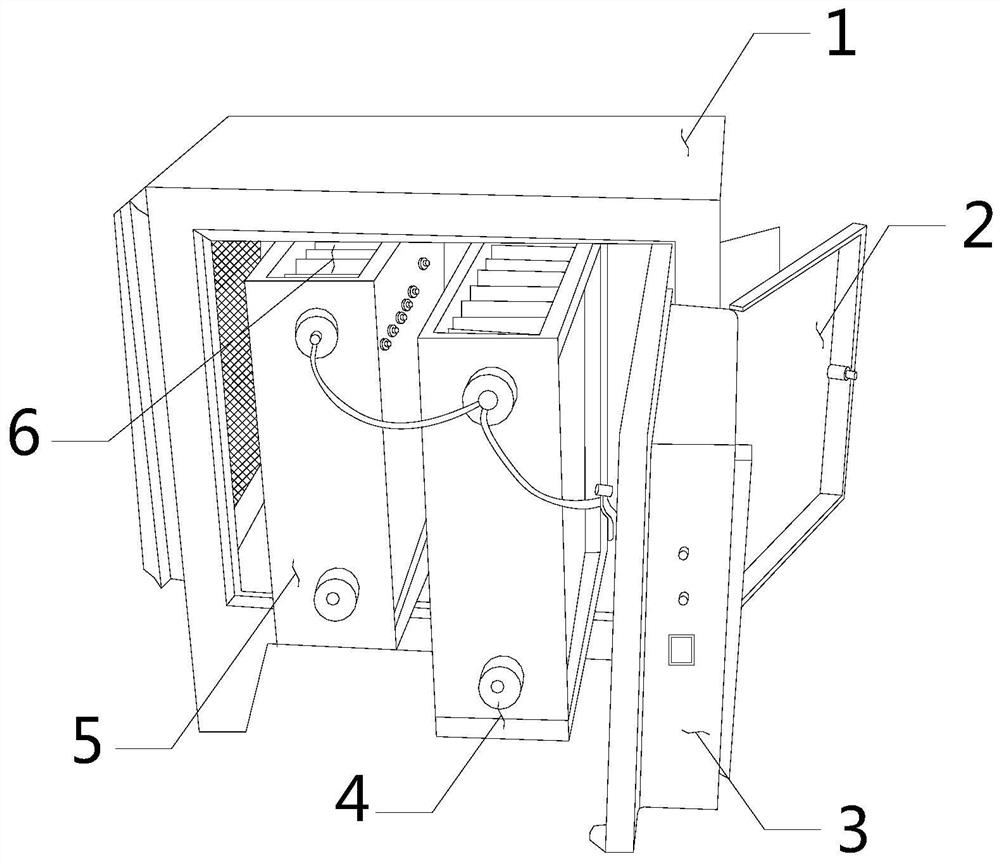

[0029] see Figure 1-Figure 3 , the present invention provides a kind of lampblack odor purification treatment equipment, its structure includes box body 1, cabinet door 2, control cabinet 3, first grid box 4, second grid box 5, grid platelet 6, said box The front end of the body 1 is provided with a cabinet door 2, and the cabinet door 2 is attached to the control cabinet 3. A first grid box 4 and a second grid box 5 are installed in the middle of the box body 1. The grid box 4 and the second grid box 5 are parallel to each other, and the second grid box 5 and the first grid box 4 are electrically connected with the control cabinet 3 by wires, and the first grid box 4 and the second grid box The inside of the grid box 5 is provided with more than two small grid plates 6 , and these small grid plates 6 are evenly and equidistantly distributed.

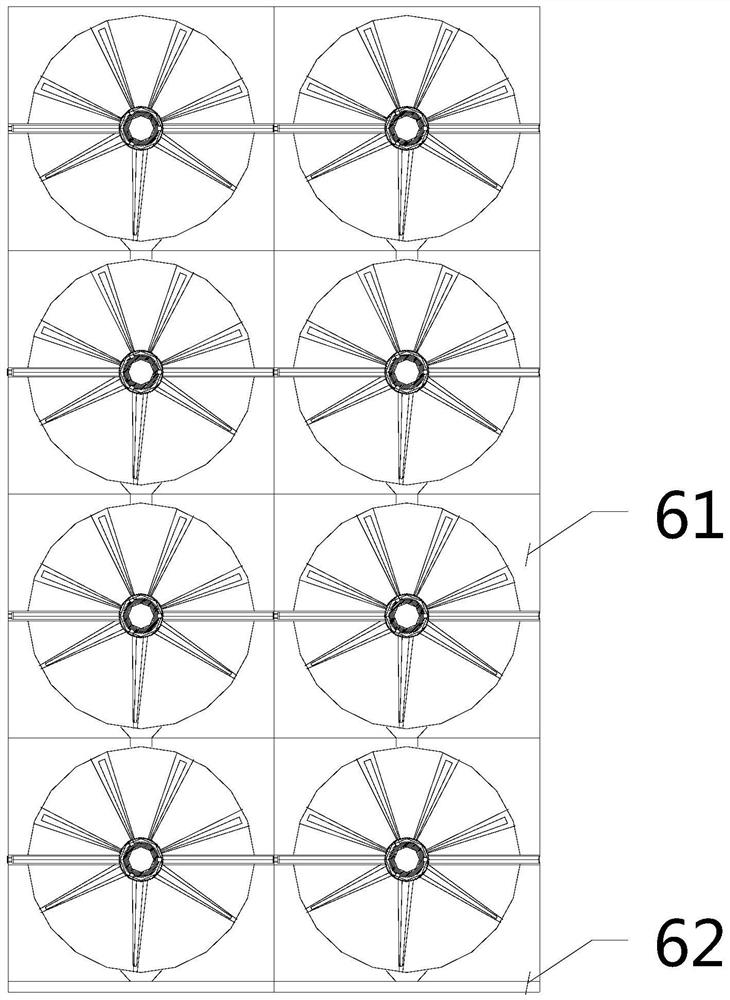

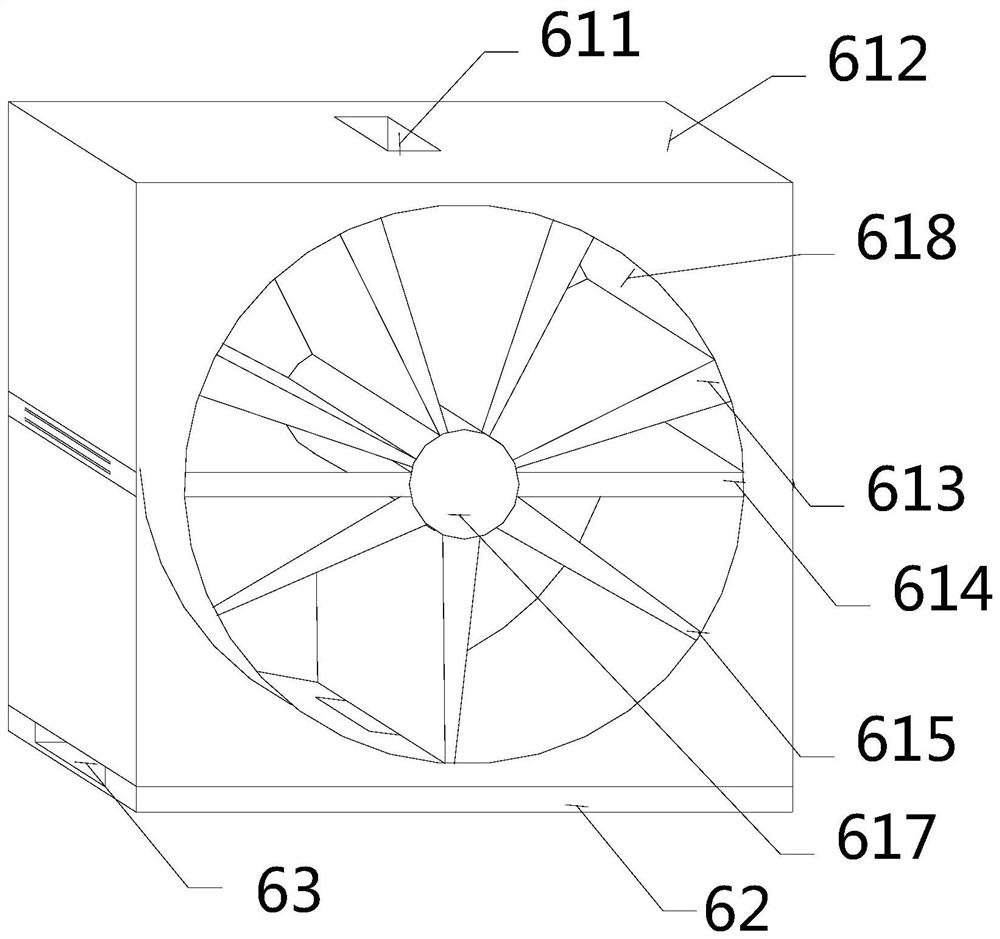

[0030] The small grid plate 6 is composed of more than two small grid plates 61 and recovery tanks 62. These small grid plates 61 ar...

Embodiment 2

[0038] see Figure 1-Figure 7, the present invention provides a kind of lampblack odor purification treatment equipment, its structure includes box body 1, cabinet door 2, control cabinet 3, first grid box 4, second grid box 5, grid platelet 6, said box The front end of the body 1 is provided with a cabinet door 2, and the cabinet door 2 is attached to the control cabinet 3. A first grid box 4 and a second grid box 5 are installed in the middle of the box body 1. The grid box 4 and the second grid box 5 are parallel to each other, and the second grid box 5 and the first grid box 4 are electrically connected with the control cabinet 3 by wires, and the first grid box 4 and the second grid box The inside of the grid box 5 is provided with more than two small grid plates 6 , and these small grid plates 6 are evenly and equidistantly distributed.

[0039] The small grid plate 6 is composed of more than two small grid plates 61 and recovery tanks 62. These small grid plates 61 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com