Energy efficiency optimization method for air cooling system of self-adaptive asynchronous particle swarm power battery pack

A technology for power battery packs and air-cooling systems, applied in design optimization/simulation, instruments, calculation models, etc., can solve the problem of optimal fan energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

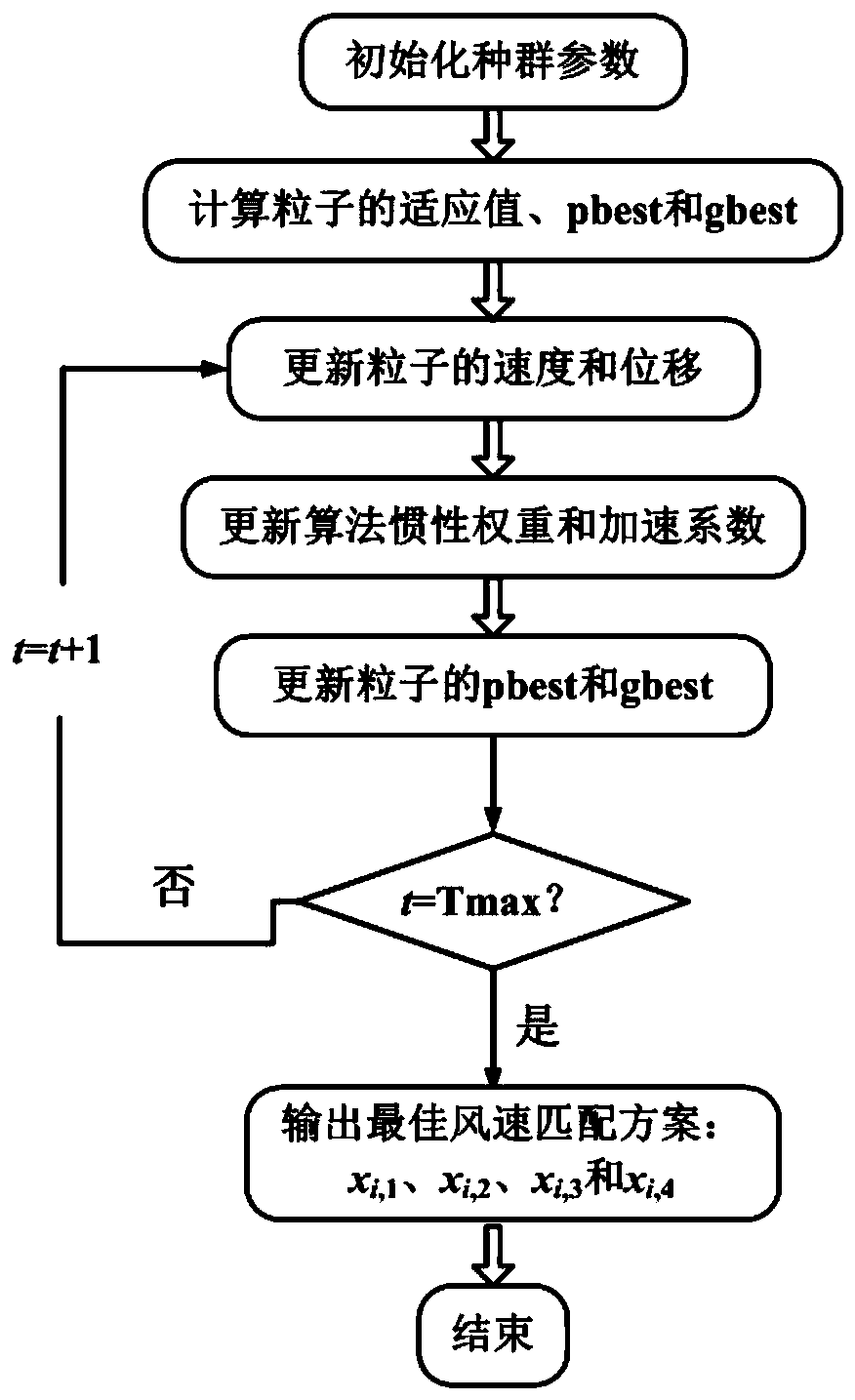

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments.

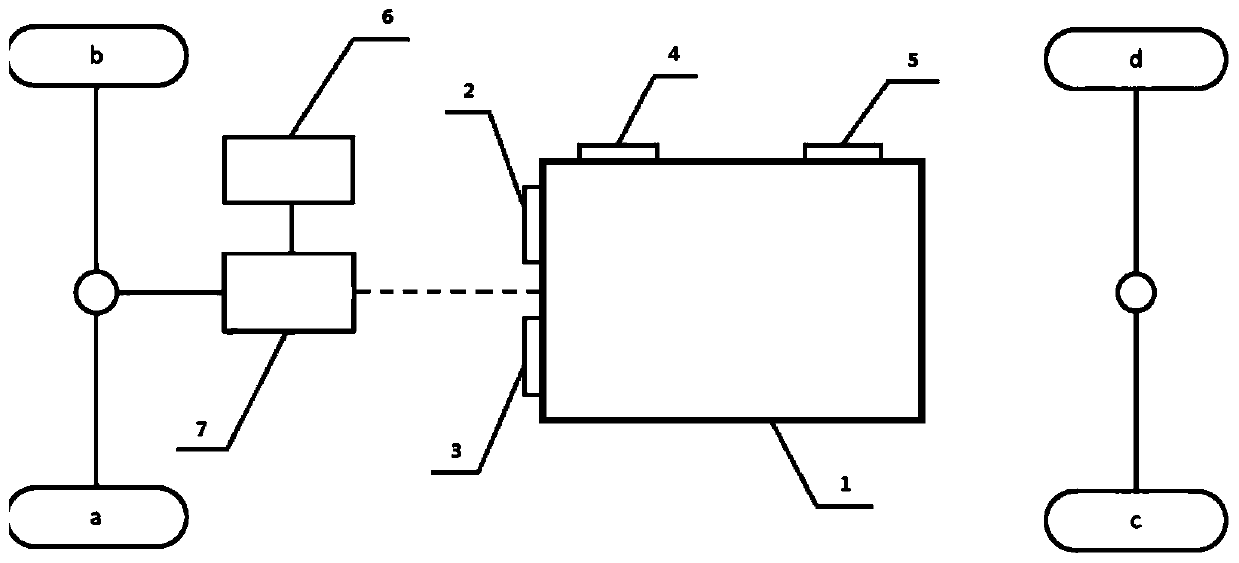

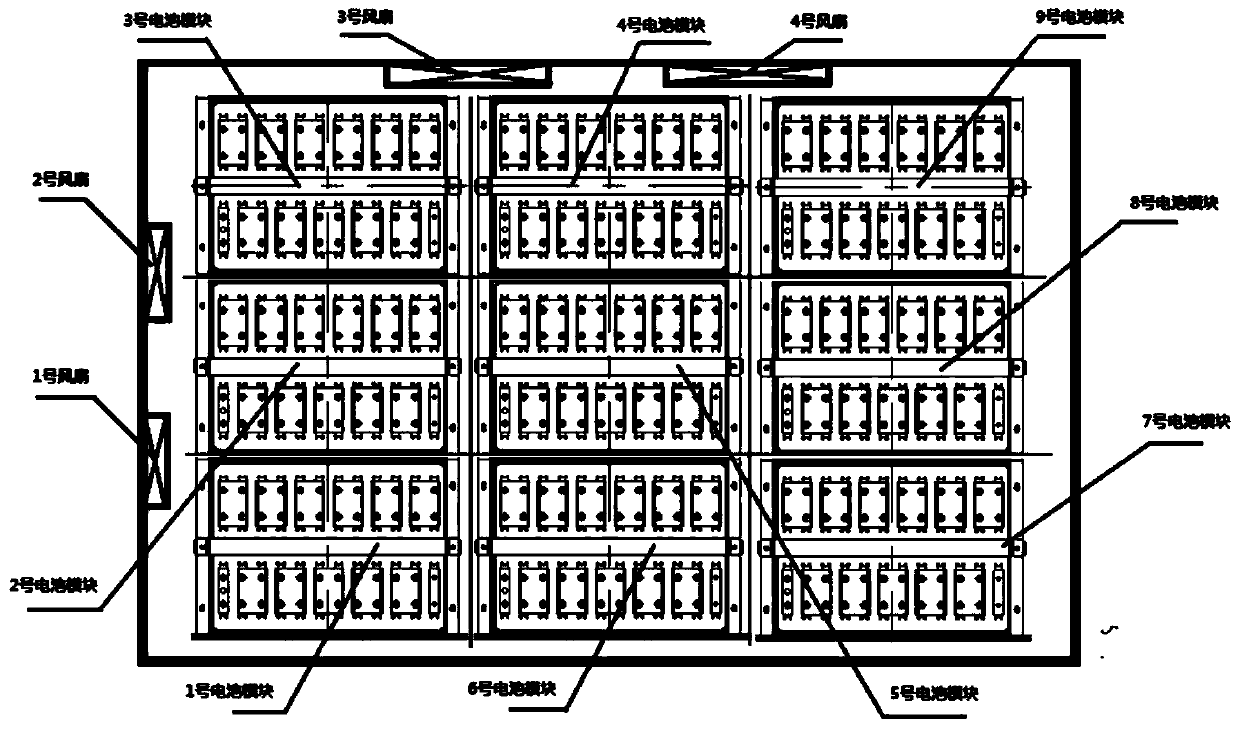

[0049] In this embodiment, the method of the present invention is applied to the power battery air cooling system of electric vehicles, such as figure 2 As shown, the electric vehicle power battery air cooling system includes a power battery pack 1, a first cooling fan 2, a second cooling fan 3, a third cooling fan 4, a fourth cooling fan 5, a drive motor 6 and a vehicle transmission 7; Group 1 has a total of nine battery modules, which are respectively recorded as No. 1-No. 9 battery modules. The battery box for placing the power battery pack 1 is arranged under the rear seat of the vehicle, and the third cooling fan 4 and the fourth cooling fan are arranged in the X direction of the vehicle. Cooling fans 5, the first cooling fan 2 and the second cooling fan 3 are arranged in the Y direction of the vehicle.

[0050] During the driving proces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com