Shell assembly, preparation method of shell assembly and electronic equipment

A technology of shell assembly and transparent shell, applied in the direction of electrical equipment shell/cabinet/drawer, chassis/cabinet/drawer parts, electrical components, etc. In order to achieve the effect of enriching visual effects, enhancing the appearance and expressing the appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0053] The present application also provides a method for preparing a shell assembly, the preparation method prepares the shell assembly 100 of any one of the above embodiments. see Figure 9 , Figure 9 It is a schematic flow chart of a method for preparing a shell assembly according to an embodiment of the present application, including the following steps:

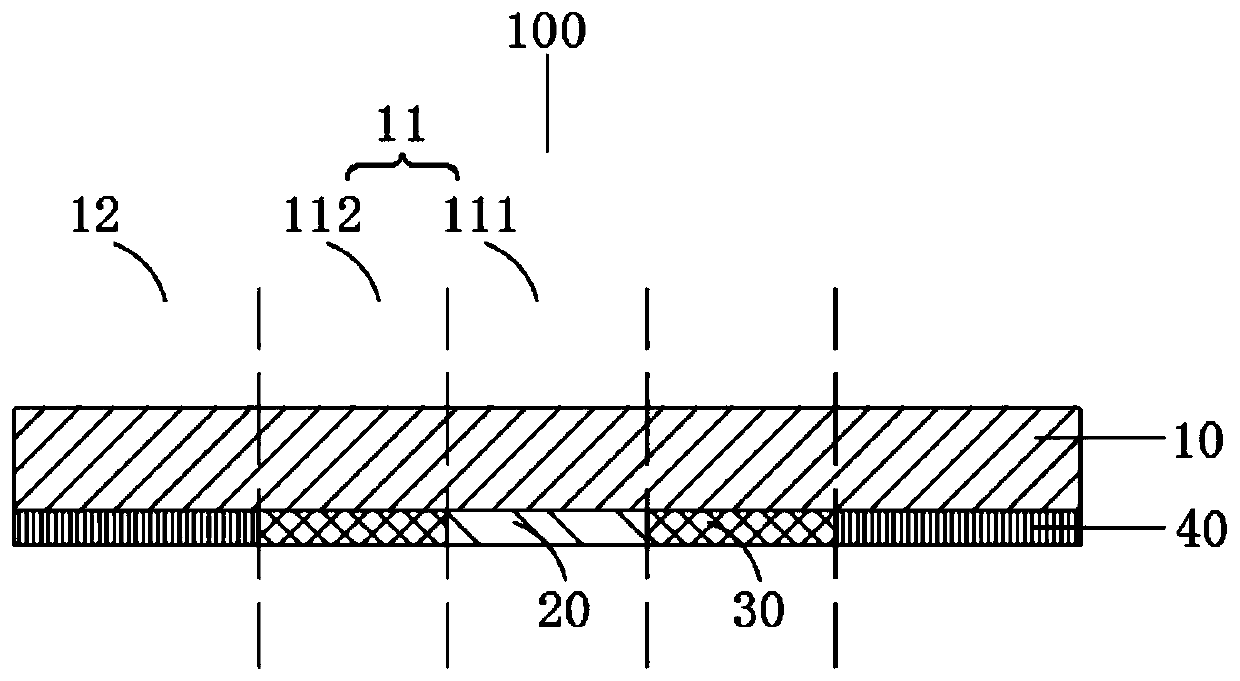

[0054] Operation 101: Provide a transparent casing, the transparent casing includes a first area and a second area adjacent to the first area, the first area includes a window area and a window area adjacent to the window area The second area of the non-window area is visually different from the non-window area.

[0055] In operation 101, the transparent casing 10 has a certain degree of light transmittance, and there is no restriction on its shape, size, material, etc., which can be selected according to actual needs. In one embodiment, the optical transmittance of the transparent housing 10 is greater than 90%, w...

Embodiment 1

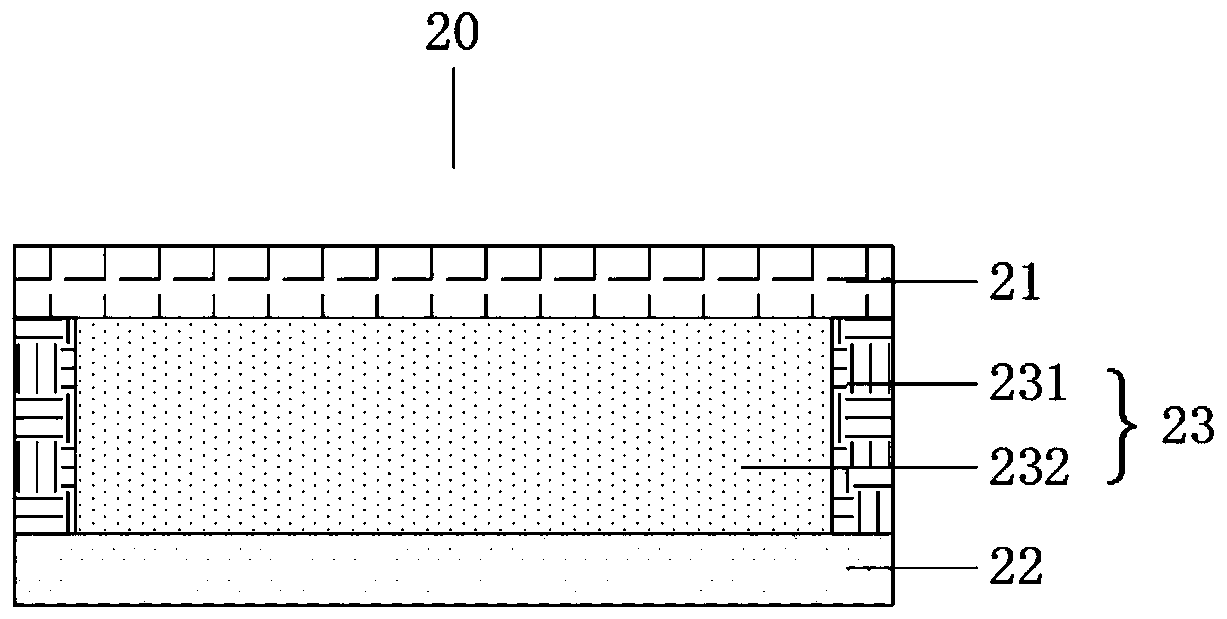

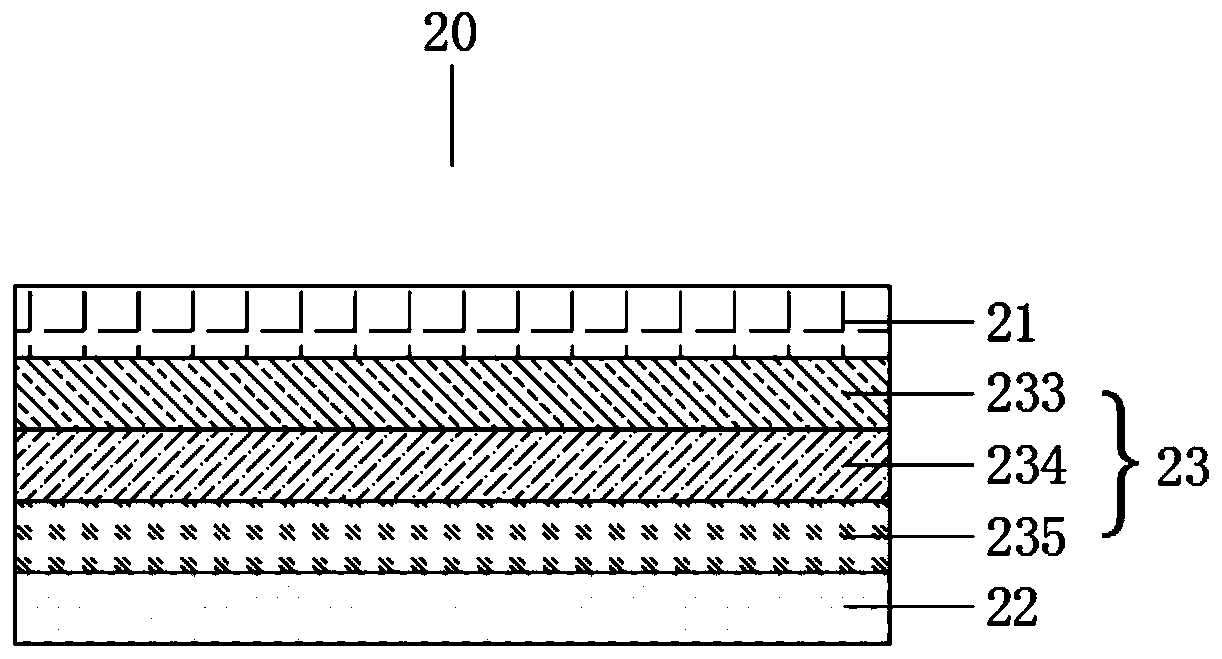

[0098] An electrochromic material solution including polyaniline and viologen is provided, wherein the concentration ratio of polyaniline and viologen is 1.5:1, and the concentration of the electrochromic material solution is 0.25 mol / L. A first transparent conductive substrate and a second transparent conductive substrate of 0.15mm are provided, and the electrochromic material solution is encapsulated between the first transparent conductive substrate and the second transparent conductive substrate through a plastic frame, wherein the thickness of the electrochromic layer is 50 μm. Under the 0.9V applied electric field, the electrochromic layer changes from a transparent state to a colored state, and the optical transmittance of the electrochromic layer in the colored state is 11%-16%, and the optical transmittance of the electrochromic layer in the transparent state is 86%-88%. After testing, the Lab values of the electrochromic layer in the colored state are L: 21.01, a:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface tension | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com