Enzyme tofu and manufacturing process thereof

A production process and enzyme water technology, applied in dairy products, cheese substitutes, applications, etc., can solve the problems of high processing and production costs, low crystallization rate of water tofu, unfavorable for users to eat, etc., to save time and facilitate safety. and digestion, the effect of saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] An enzyme water tofu, the formula comprises: soybeans and vinegar water, and the mass percentages of each component are: 80% soybeans and 20% vinegar water.

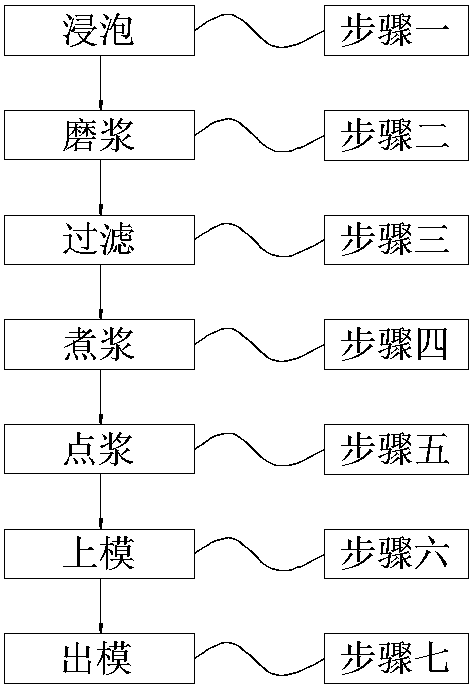

[0028] A manufacturing process of enzyme water tofu, comprising the following steps, step 1, soaking; step 2, grinding; step 3, filtering; step 4, boiling; out of the mold;

[0029] Wherein in above-mentioned step one, soaking comprises the following steps:

[0030] 1) Select a certain amount of soybeans and place them in a pot;

[0031] 2) Pour a certain amount of water over the top of the soybeans and soak for 4-6 hours;

[0032] In the above step 2, the soybeans in the above step 2 are picked up to control the water. The section of the soaked soybeans has no hard core, and the quality after absorbing water is 2-2.5 times that of before soaking. Pour it into a refiner, add a certain amount of water, and grind pulp to obtain soybean milk;

[0033] Wherein in above-mentioned step 3, the soybean milk obtained i...

Embodiment 2

[0039] An enzyme water tofu, the formula comprises: soybeans and vinegar water, and the mass percentages of each component are: 85% soybeans and 15% vinegar water.

[0040] A manufacturing process of enzyme water tofu, comprising the following steps, step 1, soaking; step 2, grinding; step 3, filtering; step 4, boiling; out of the mold;

[0041] Wherein in above-mentioned step one, soaking comprises the following steps:

[0042] 1) Select a certain amount of soybeans and place them in a pot;

[0043] 2) Pour a certain amount of water over the top of the soybeans and soak for 4-6 hours;

[0044] In the above step 2, the soybeans in the above step 2 are picked up to control the water. The section of the soaked soybeans has no hard core, and the quality after absorbing water is 2-2.5 times that of before soaking. Pour it into a refiner, add a certain amount of water, and grind pulp to obtain soybean milk;

[0045] Wherein in above-mentioned step 3, the soybean milk obtained i...

Embodiment 3

[0051] An enzyme water tofu, the formula comprises: soybeans and vinegar water, and the mass percentages of each component are: 90% soybeans and 10% vinegar water.

[0052] A manufacturing process of enzyme water tofu, comprising the following steps, step 1, soaking; step 2, grinding; step 3, filtering; step 4, boiling; out of the mold;

[0053] Wherein in above-mentioned step one, soaking comprises the following steps:

[0054] 1) Select a certain amount of soybeans and place them in a pot;

[0055] 2) Pour a certain amount of water over the top of the soybeans and soak for 4-6 hours;

[0056] In the above step 2, the soybeans in the above step 2 are picked up to control the water. The section of the soaked soybeans has no hard core, and the quality after absorbing water is 2-2.5 times that of before soaking. Pour it into a refiner, add a certain amount of water, and grind pulp to obtain soybean milk;

[0057] Wherein in above-mentioned step 3, the soybean milk obtained i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com