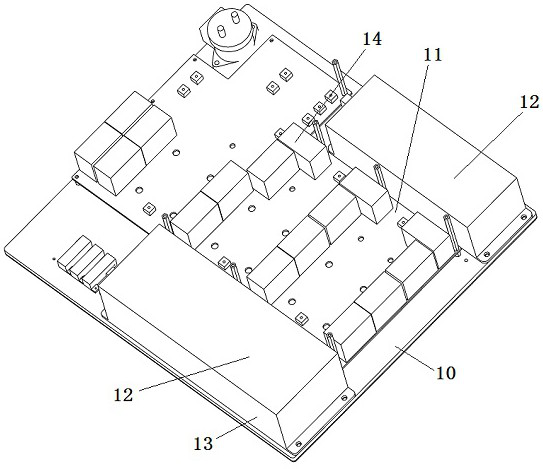

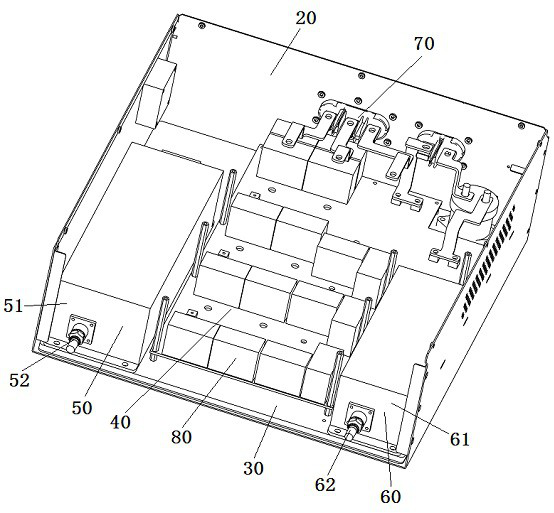

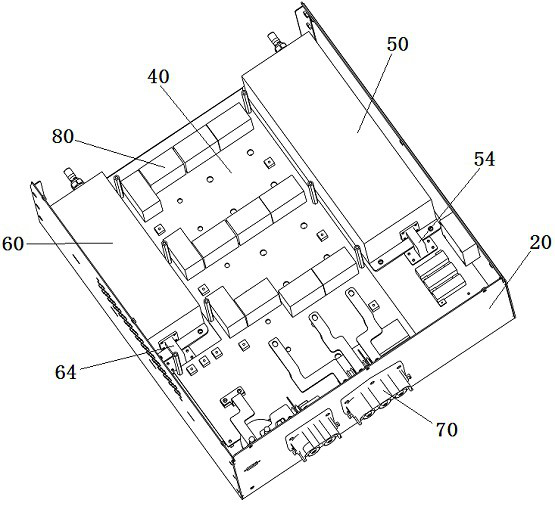

Charge and discharge module and its inductance element

A charging and discharging module and inductive element technology, which is applied in the direction of electrical components, charging stations, transformer/inductive components, etc., can solve the problem that the cold plate cannot meet the heat dissipation requirements of the inductive element, so as to avoid heat concentration, high heat dissipation efficiency, Good cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0074] Embodiment 2 of the charge-discharge module in the present invention: the difference from the above-mentioned embodiment is that the installation shell in this embodiment only includes side walls arranged vertically on the cold plate, and the side walls are connected to each other to form the installation shell. frame structure. At this time, the potting compound fixes the coil in the installation shell by adhering to the side wall. Each side wall is provided with a refrigerant flow channel, and the refrigerant flow channels in adjacent side walls are connected. The side walls enclose the coil laterally, and the bottom of the coil is directly in contact with the cold plate. At this time, a cooling flow channel at the bottom of the coil may be provided in the cold plate, and the cooling flow channel communicates with the refrigerant flow channel and shares a cold source.

Embodiment 3

[0075] Embodiment 3 of the charging and discharging module in the present invention: the difference from the above embodiments is that the inlet and outlet of the refrigerant channel in the installation shell in this embodiment are connected to the corresponding interface on the cold plate, and the one connected to the external cold source The total refrigerant inlet and refrigerant outlet are arranged on the cold plate.

[0076] Embodiment 4 of the charging and discharging module in the present invention: the difference from the above embodiments is that in this embodiment, when processing the refrigerant flow channel in the shell wall of the installation shell, the method of embedding the cold pipe is adopted, and the preformed refrigerant The tube is buried in the shell wall of the installation shell, and no longer directly machined on the shell wall to form the refrigerant flow channel. Alternatively, the shell wall of the installation shell is formed by the combination of...

Embodiment 5

[0077] Embodiment 5 of the charging and discharging module in the present invention: the difference from the above embodiments is that the refrigerant outlet and the refrigerant inlet on the installation shell in this embodiment are respectively arranged on two adjacent shell walls, and are not limited to The refrigerant inlet and refrigerant outlet must be arranged on two opposite shell walls.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com