Roller press and method for determining the filling level

A pressing machine and roll type technology, applied in the direction of presses, material forming presses, manufacturing tools, etc., can solve maintenance troubles and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

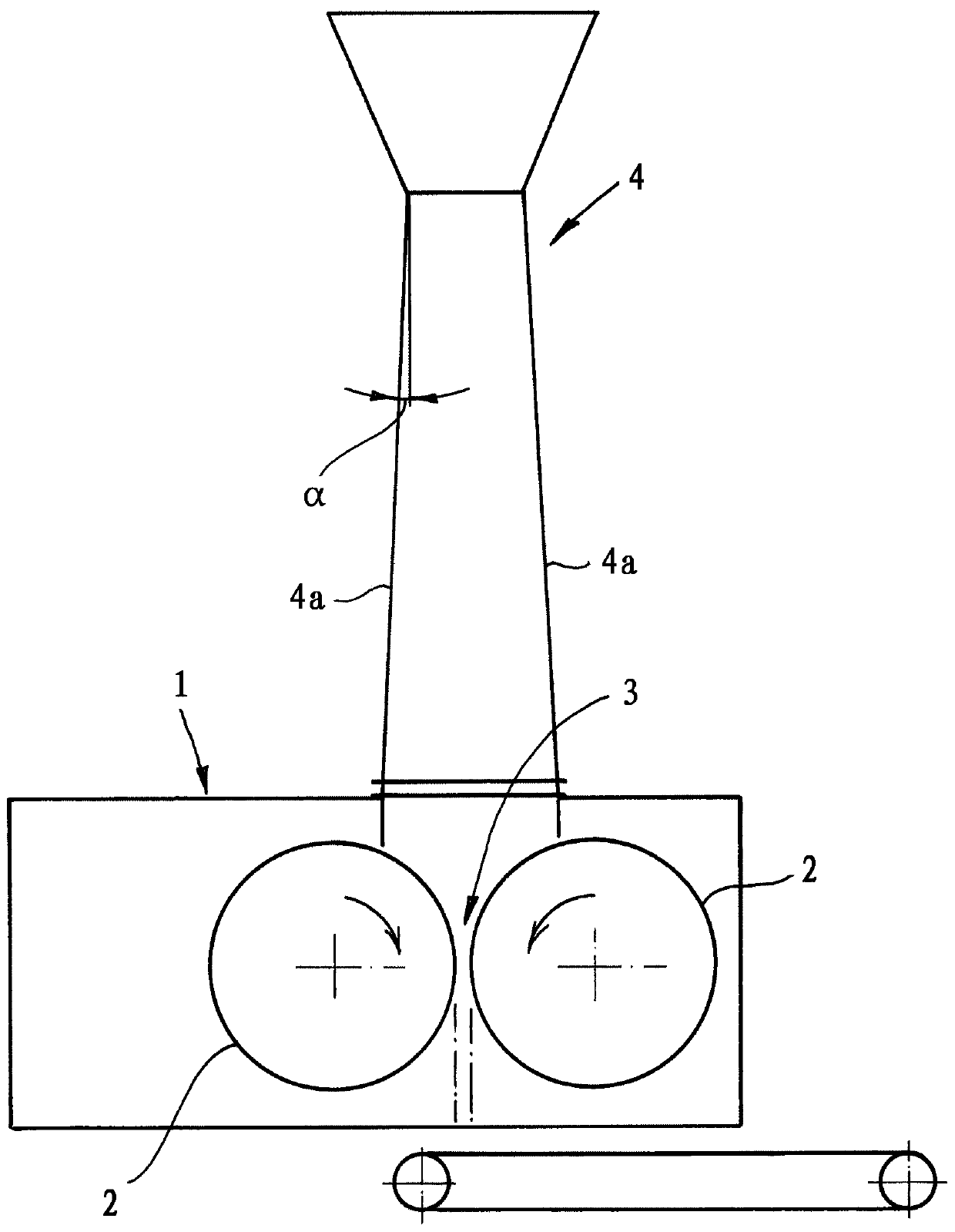

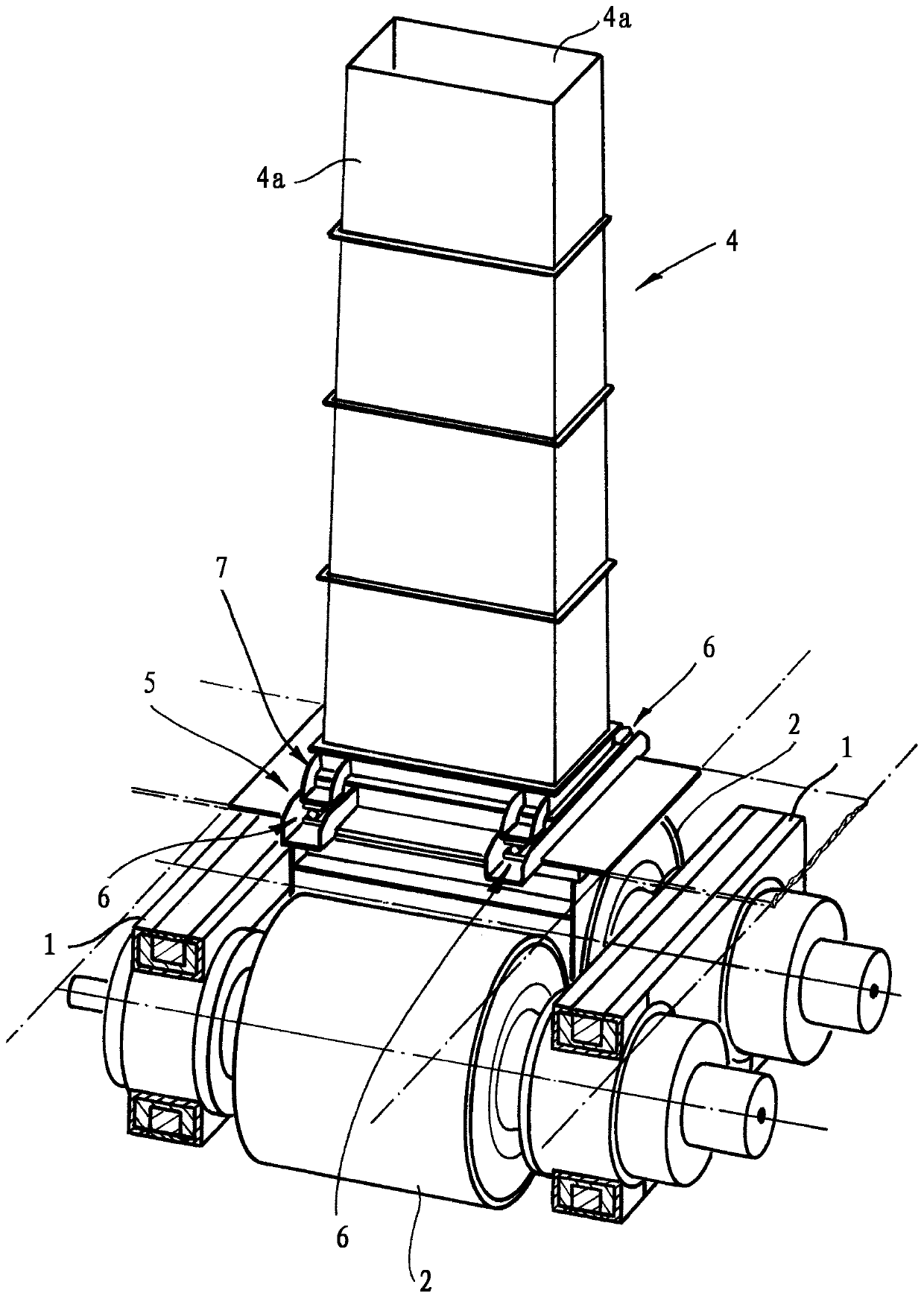

[0026] The drawing shows a roller press as an embodiment of a high-pressure roller mill. In this exemplary embodiment, the high-pressure roller mill is used for grinding material, for example ore-containing material. It is particularly preferred here that it is a concentrate (for example iron ore concentrate), which may also have a relatively low flowability due to its moisture.

[0027] The roll press has a press stand 1 and two rolls 2 arranged adjacent to each other in the press stand 1 , between which a roll gap 3 is formed. The two rolls 2 are rotationally driven in opposite directions by drives not shown. Arranged above the roll gap 3 is a feed hopper 4 through which material is supplied to the roll gap 3 . In the present exemplary embodiment, the feed hopper has at least two opposite hopper walls 4a, each of which is inclined at an angle α towards the vertical, so that the feed hopper 4 has a cross-section that widens from top to bottom. The (negative) angle α can he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com