Light interference lipid layer composite material as well as construction method and application thereof

A composite material, lipid layer technology, applied in the field of reflection interference, can solve problems such as difficulty, inability to achieve real-time tracking and monitoring, no optical interference characteristics, etc., to achieve the effect of sensitive response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

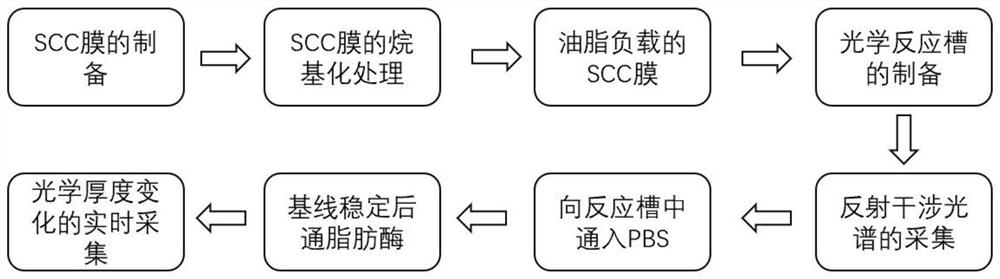

[0048] A method for monitoring lipolysis reaction in situ in real time, comprising the following steps:

[0049] (1) Soak the glass sheet in piranha solution for 120 minutes, rinse it with water three times, and dry it in a fume hood at 115°C to prepare a hydrophilic glass sheet.

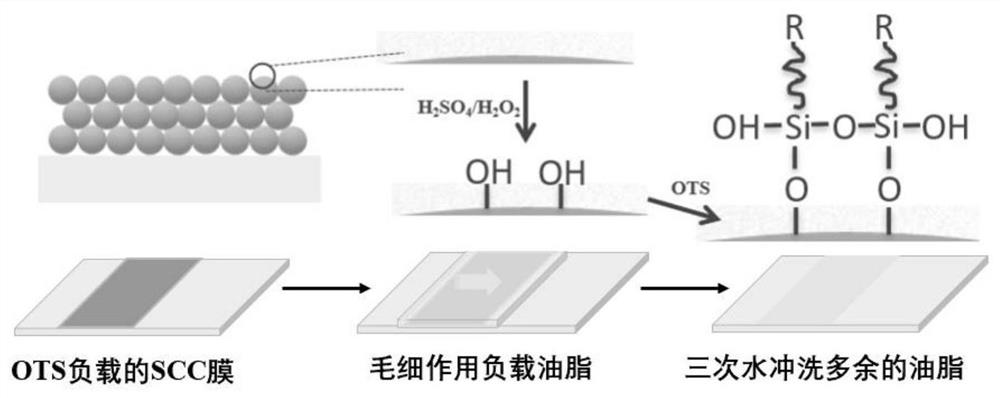

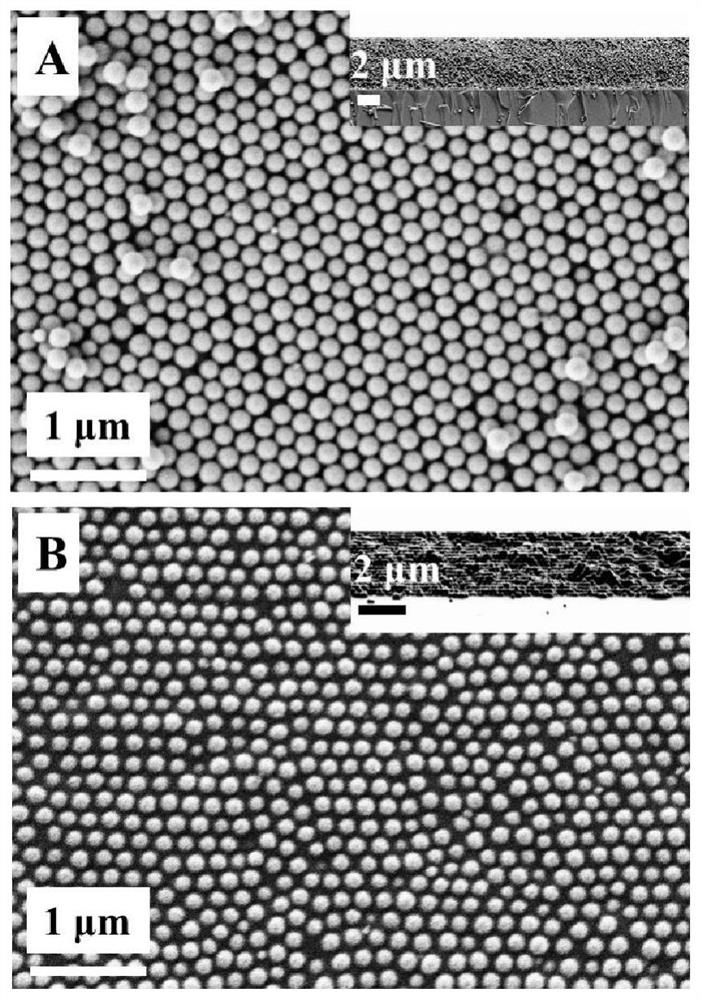

[0050] (2) Disperse 0.9 g of silica sphere solution in 100 mL of absolute ethanol to prepare a silica colloidal microsphere / absolute ethanol solution with a mass volume ratio of 0.9%. Put the hydrophilic glass flakes prepared in step (1) in the colloidal silica microsphere / absolute ethanol solution, adopt the vertical evaporation method, control the humidity to be 7.5%, and control the temperature at 20°C. After a week of growth, the Silica colloidal crystal thin films were prepared on the surface of glass flakes. The silica colloidal crystal film was taken out to dry, soaked in piranha solution for 50 minutes, rinsed with water and absolute ethanol three times in sequence, and dried with nitrogen ...

Embodiment 2

[0065] Test method is the same as embodiment 1, wherein in the step (1), the colloidal silica microsphere / dehydrated alcohol solution concentration is changed into 0.8%, in the step (2), in the vertical evaporation method, the air humidity is controlled to be 10%, and the temperature is controlled to be 18°C, soak the silica colloidal crystal film in piranha solution for 40 minutes; in step (3), the alkylating agent is changed to hexamethylenediaminomethyltrimethoxysilane; in steps (7) and (8), The flow rate of the PBS buffer solution and the lipase solution was 0.06mL / min, and the thickness of the silicon dioxide colloidal crystal film was 3500nm.

Embodiment 3

[0067] Test method is the same as embodiment 1, wherein, in the step (1), the colloidal silica microsphere / dehydrated alcohol solution concentration is changed into 1.0%, in the vertical evaporation method in the step (2), the air humidity is controlled to be 8.0%, and the temperature control is At 22°C, soak the silica colloidal crystal film in piranha solution for 70 minutes; in steps (7) and (8), feed PBS buffer solution and lipase at a flow rate of 0.3mL / min to obtain silica colloidal crystals The thickness of the film was 5500 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com