Toilet cleaning brush

A cleaning brush and toilet technology, applied in the field of sanitary ware, can solve the problems of low cleaning power, long drying time, difficult to remove dirt, etc., and achieve the effect of high cleaning power and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

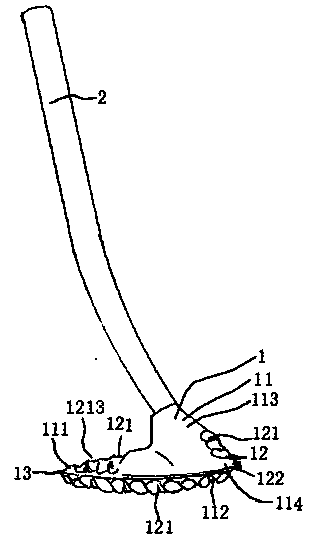

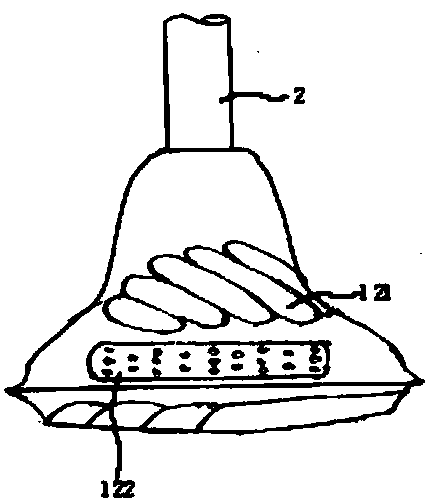

[0046] Such as Figure 1-5 , Figure 15-17 As shown, a toilet cleaning brush includes a brush head 1 and a handle 2; the brush head 1 includes a cleaning part 11 and a cleaning part 12.

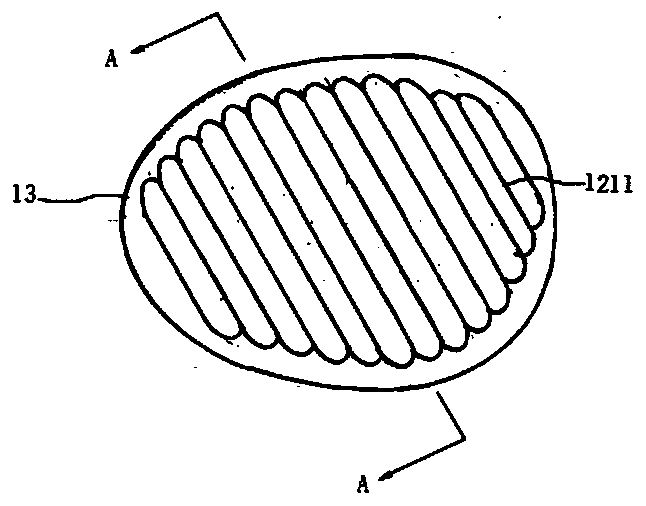

[0047]The cleaning section 11 is a shoe-shaped cleaning section. The cleaning part 12 comprises a first cleaning part 121 and a second cleaning part 122; the cleaning part 11 comprises a first cleaning part 111, a second cleaning part 112, a third cleaning part 113 and a fourth cleaning part 114; the second cleaning part 112 is located at The bottom of the brush head 1, the first cleaning part 111 is located at the front side of the top of the brush head 1, the third cleaning part 113 is located at the rear side of the top of the brush head 1, and the fourth cleaning part 114 is located below the third cleaning part 113; The cleaning parts 121 are arranged on the surfaces of the first cleaning part 111, the second cleaning part 112 and the third cleaning part 113, and there are more than tw...

Embodiment 2

[0068] Such as figure 1 , 2 , 7-9, and 15-17, a toilet cleaning brush includes a brush head 1 and a handle 2; the brush head 1 includes a cleaning part 11 and a cleaning part 12.

[0069] The cleaning section 11 is a shoe-shaped cleaning section. The cleaning part 12 includes a first cleaning part 121 and a second cleaning part 122; the cleaning part 11 includes a first cleaning part 111, a second cleaning part 112 and a third cleaning part 113; the second cleaning part 112 is located at the bottom of the brush head 1, The first cleaning part 111 is positioned at the front side of the top of the brush head 1, the third cleaning part 113 is positioned at the rear side of the top of the brush head 1, and the first cleaning part 121 is arranged on the first cleaning part 111, the second cleaning part 112 and the third cleaning part 111. On the surface of the cleaning part 113, there are more than two first cleaning parts 121. The first cleaning part 121 is formed with an inward...

Embodiment 3

[0091] Such as Figure 6-9 , 17, a toilet cleaning brush, including a brush head 1 and a handle 2;

[0092]The cleaning section 11 is a shoe-shaped cleaning section. The cleaning part 12 comprises the first cleaning part 121; the cleaning part 11 comprises the first cleaning part 111, the second cleaning part 112, the third cleaning part 113 and the fourth cleaning part (not shown); the second cleaning part 112 is located at The bottom of the brush head 1, the first cleaning part 111 is located at the front side of the top of the brush head 1, the third cleaning part 113 is located at the rear side of the top of the brush head 1, and the fourth cleaning part is located below the third cleaning part 113; the first cleaning Parts 121 are arranged on the surface of the first cleaning part 111, the second cleaning part 112 and the third cleaning part 113, the first cleaning part 121 is provided with more than two, and the first cleaning part 121 is formed with an inwardly recesse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com