Dish-washing machine

A technology for dishwashers and spray arms, which is applied to tableware washing machines/rinsing machines, tableware washing machines/rinsing and rinsing machine parts, cleaning equipment, etc., which can solve the problems of limited cleaning range of spray arms and inability to effectively clean them. Achieve stable spray operation, improve cleaning ability, and improve stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

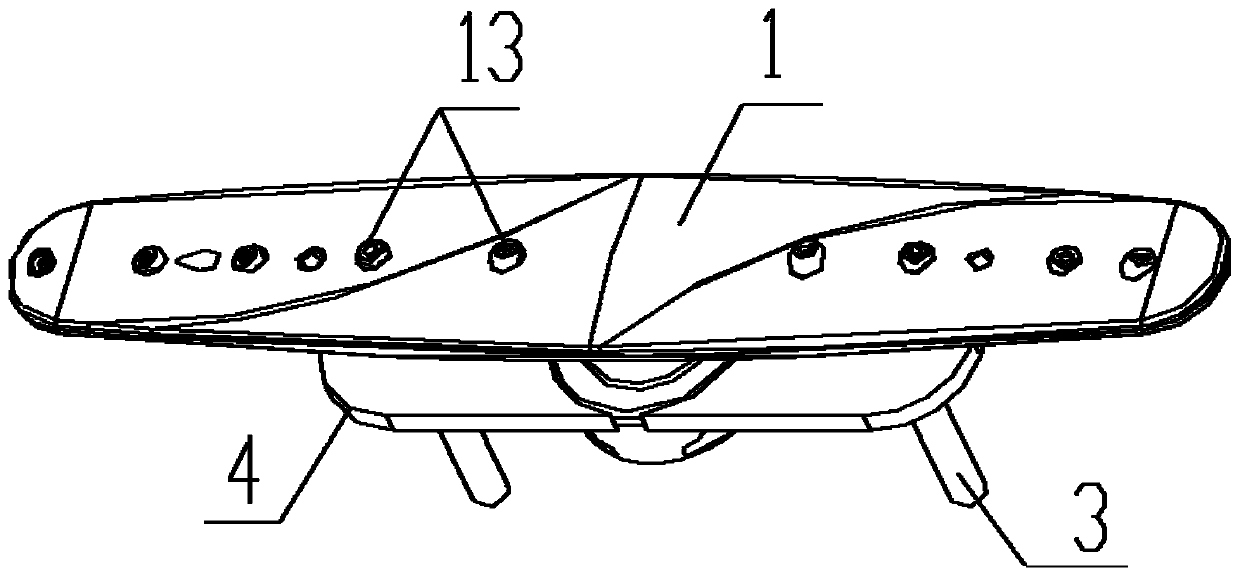

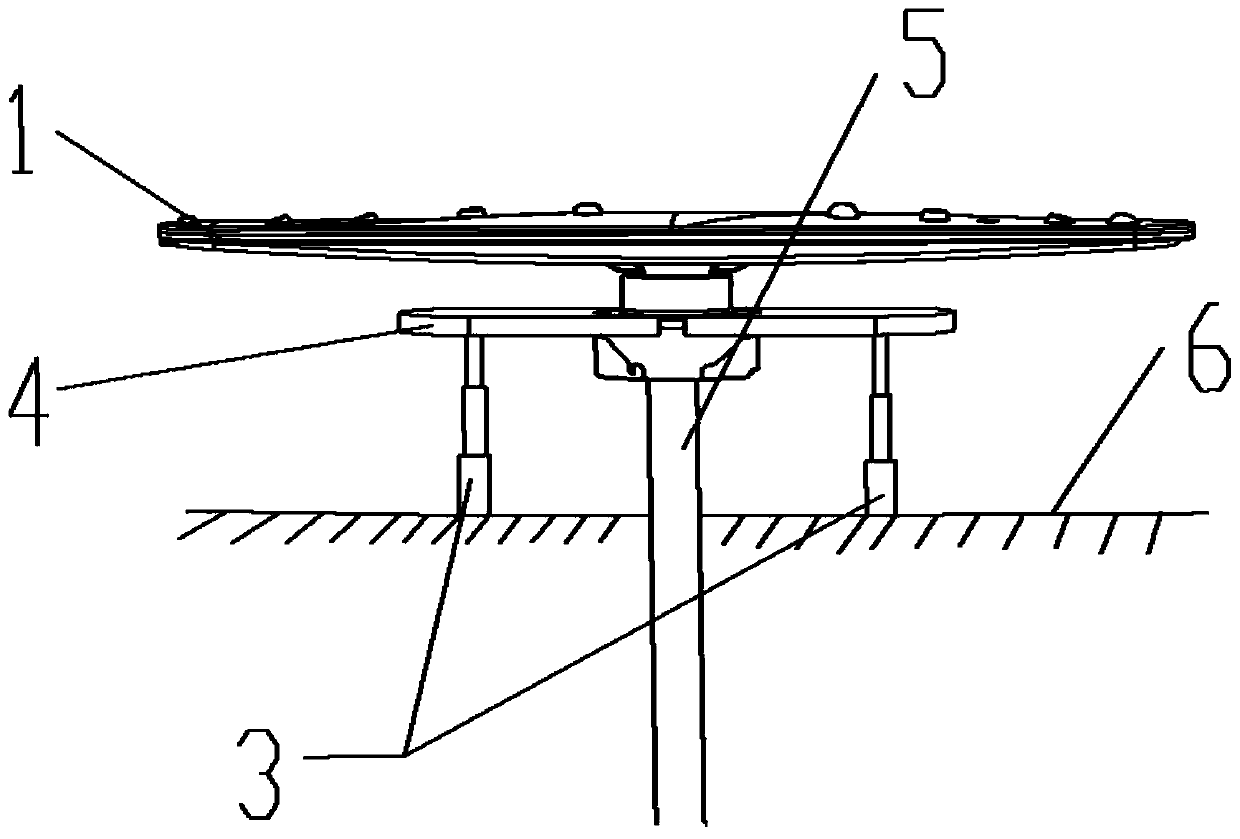

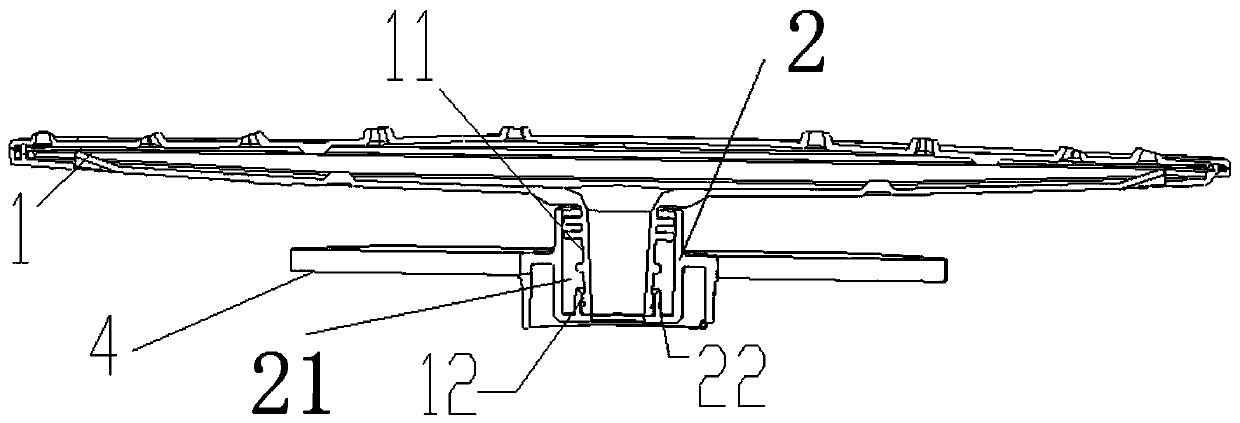

[0037] This embodiment provides a dishwasher, such as figure 1 and figure 2 As shown, it includes: a housing 6 with a spray arm cavity inside; a spray arm structure located in the spray arm cavity and rotatably connected to the water pipe (5). In this embodiment, the water pipe 5 is a bellows. The spray arm structure includes a spray arm 1 and a spray arm seat 2, the spray arm 1 can rotate relative to the spray arm seat 2; a lifting structure 3, one end acts on the housing 6, and the other end acts on the On the spray arm seat 2, the lifting structure 3 is suitable for pushing the spray arm structure to move along the height direction in the spray arm chamber.

[0038] In this embodiment, a through hole is provided on the spray arm seat 2, and the water pipe 5 is connected to the spray arm through the through hole, and supplies water to the spray arm. At the same time, the spray arm is provided with an inclined spray hole 13, and the water flow provides the power to rotate ...

Embodiment 2

[0045] In this embodiment, the lifting structure 3 itself can directly act on the spray arm seat 2. At this time, the movable end of the lifting structure 3 can be connected to the spray arm seat 2 by welding or binding, or even directly against the spray arm seat 2. Bottom position of arm base 2.

[0046] As a modification, the lifting structure 3 can act indirectly on the spray arm seat 2, such as figure 2 As shown, the spray arm support plate 4 can be provided at this time, and the spray arm support plate 4 connects the spray arm support 2 and the lifting structure 3 at the same time.

[0047] By setting the spray arm support plate 4, the lifting structure 3 is prevented from directly acting on the spray arm. When the spray arm needs to be replaced or cleaned, the spray arm can be directly disassembled. By setting the spray arm seat supporting plate 4, the lifting of the spray arm itself can be realized, and the disassembly convenience of the spray arm can also be improve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com