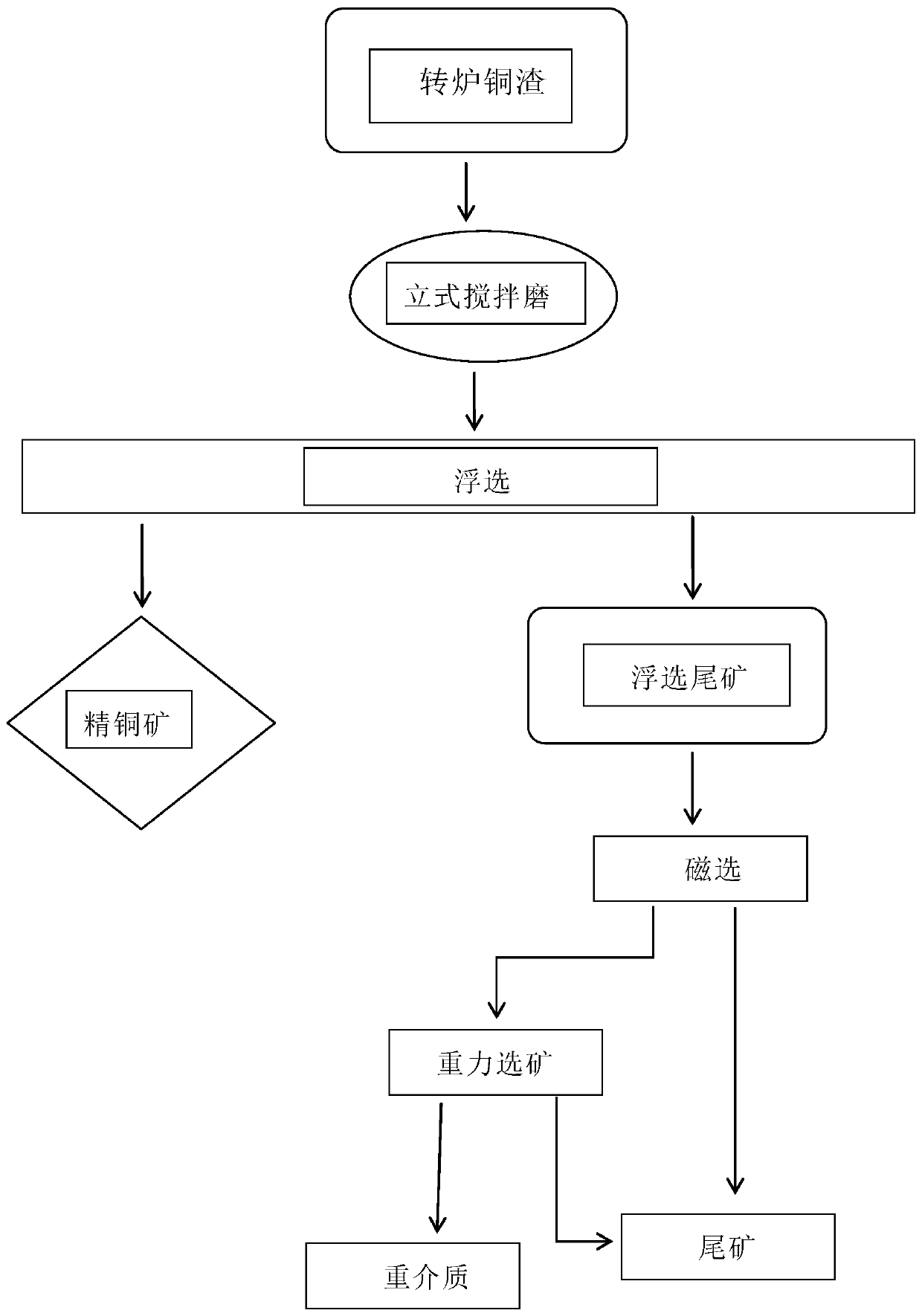

Converter copper slag deep smelting process

A converter copper and depth technology, applied in the direction of solid separation, wet separation, chemical instruments and methods, etc., can solve the problem of low utilization rate of converter copper slag, and achieve the effect of solving low utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Converter copper smelting slag is used as raw material to select copper tailings, the proportion of raw material is 4.05, and the content of magnetic substances is 55%. The raw material is released into the vertical stirring mill for stirring, and after stirring, flotation is carried out to separate the copper concentrate, and the remaining flotation The tailings are put into a magnetic field with multi-level magnetic field strength for magnetic separation, and the non-magnetic tailings are separated through a rough and two-fine magnetic separation process, and the rest of the magnetic separation concentrate is subjected to gravity separation using a concentrated cyclone , to obtain a specific gravity of 4.40, a dense medium with a magnetic substance content of 95%, that is, cyclone grit. Dense medium yield was 32%. Dense media can be used for secondary use.

Embodiment 2

[0020] Example 2 adopts the same process flow as Example 1, the difference is that the specific gravity of the raw material is 4.15, the content of magnetic substances is 59%, and the dense medium with a specific gravity of 4.45 and a content of magnetic substances of 95% is obtained, that is, cyclone sand settling. The heavy medium yield was 35%.

[0021] To sum up, in the deep smelting process of converter copper slag, the converter copper slag is subjected to steps such as stirring, flotation, magnetic separation and gravity separation to separate the components with higher iron content in the converter copper slag, which are carried out in the form of dense medium. Secondary utilization solves the defect of low utilization rate of converter copper slag.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com