System for anti-impact air valve for automatic processing ventilation system

A ventilation system and anti-shock technology, which is applied in metal processing equipment, manufacturing tools, feeding devices, etc., can solve the problems of inconvenient operation of steel plate picking, and achieve the effect of avoiding random movement and ensuring compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

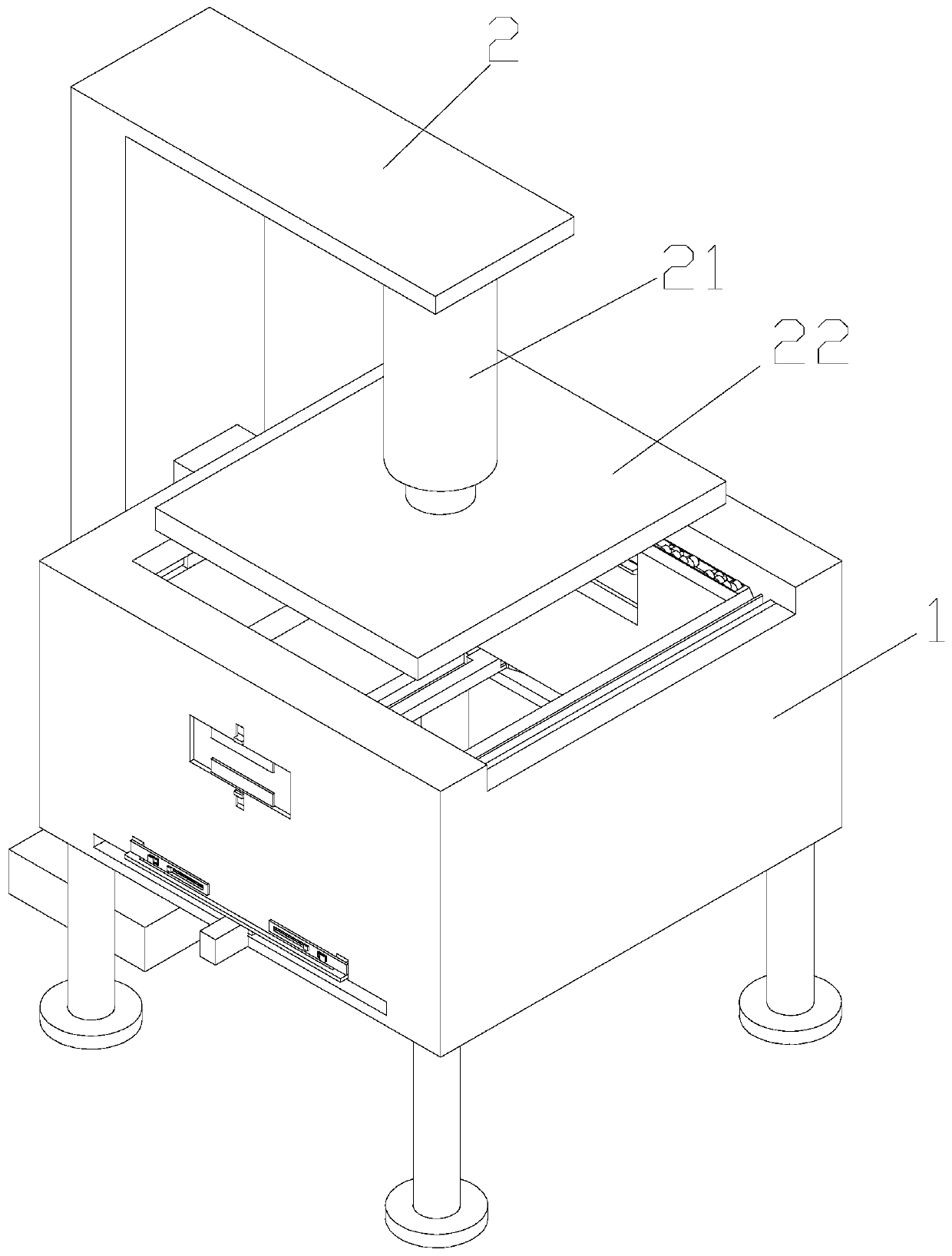

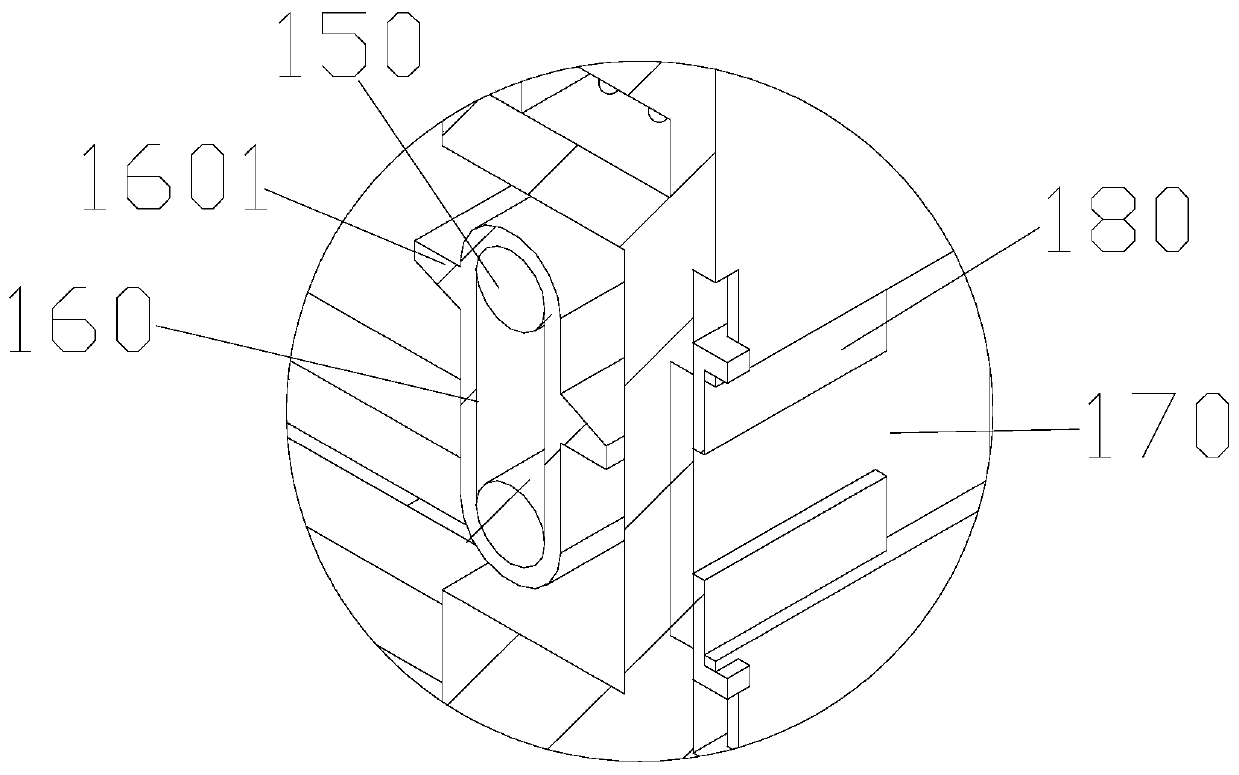

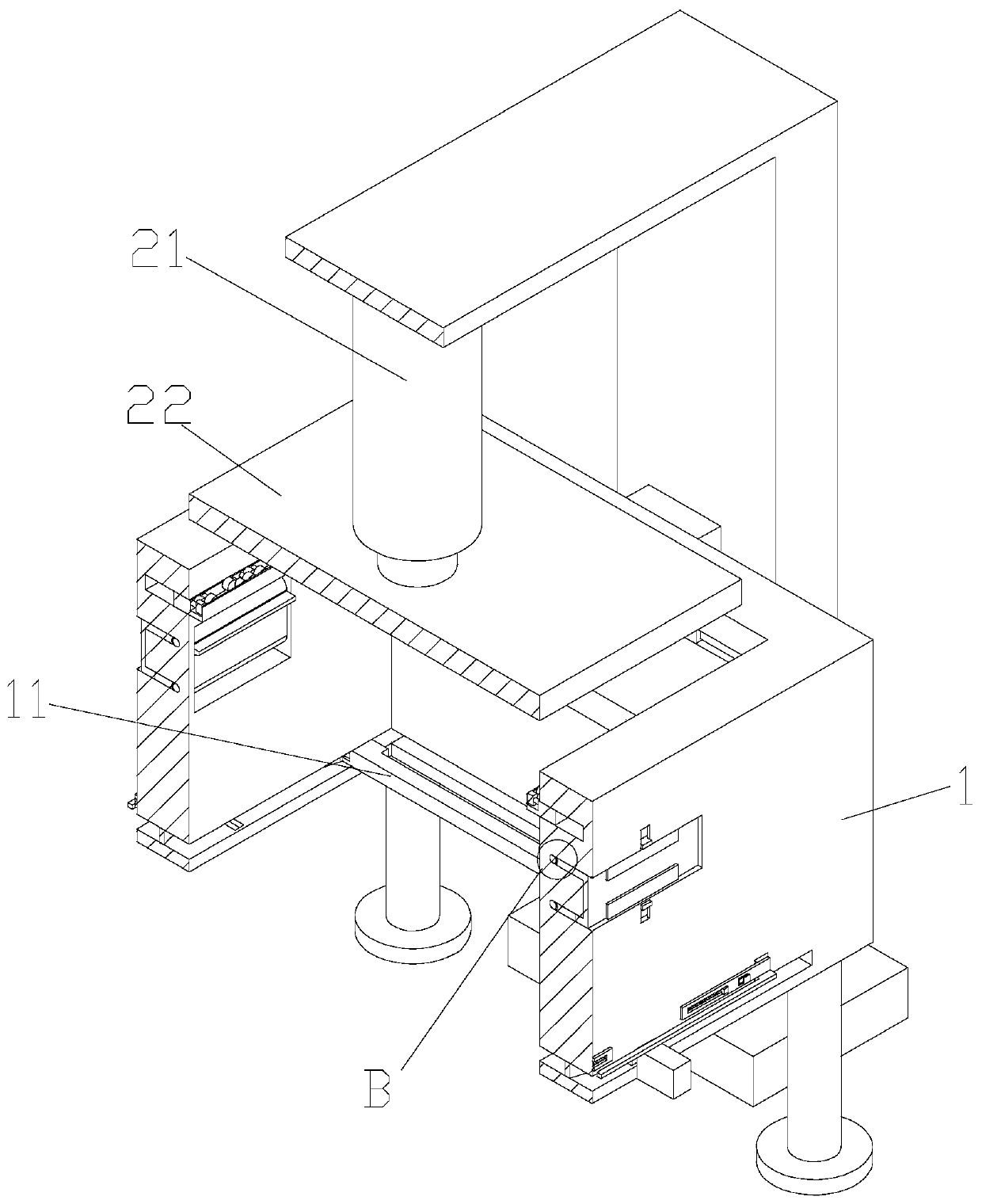

[0035] Such as Figure 1-19 As shown, a system for an anti-shock air valve used in an automatic processing ventilation system includes a processing table 1 and a mounting frame 2 arranged on one side of the processing table 1, and the top of the mounting frame 2 is arranged on the processing table 1, a hydraulic cylinder 21 is provided at the bottom of the installation frame 2, and a pressure block 22 is provided on the piston rod of the hydraulic cylinder 21. A first through cavity is provided on the processing table 1, and the inner wall of the first through cavity A first support block 12 is provided, a first movable groove is also provided on the inner wall of the first first through cavity, a support rod 11 is provided in the first movable groove, and a support rod 11 is provided on the side wall of the processing table 1 for Drive the cylinder 141 to move the support rod 11, the side wall of the first support block 12 is provided with a ninth movable groove matching with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com