Electric power steering system and method used for generating steering system

A technology of electric power steering and steering system, which is applied in power steering mechanism, electric steering mechanism, steering mechanism, etc., and can solve problems such as annoying noise, worm shaft and worm gear disengagement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

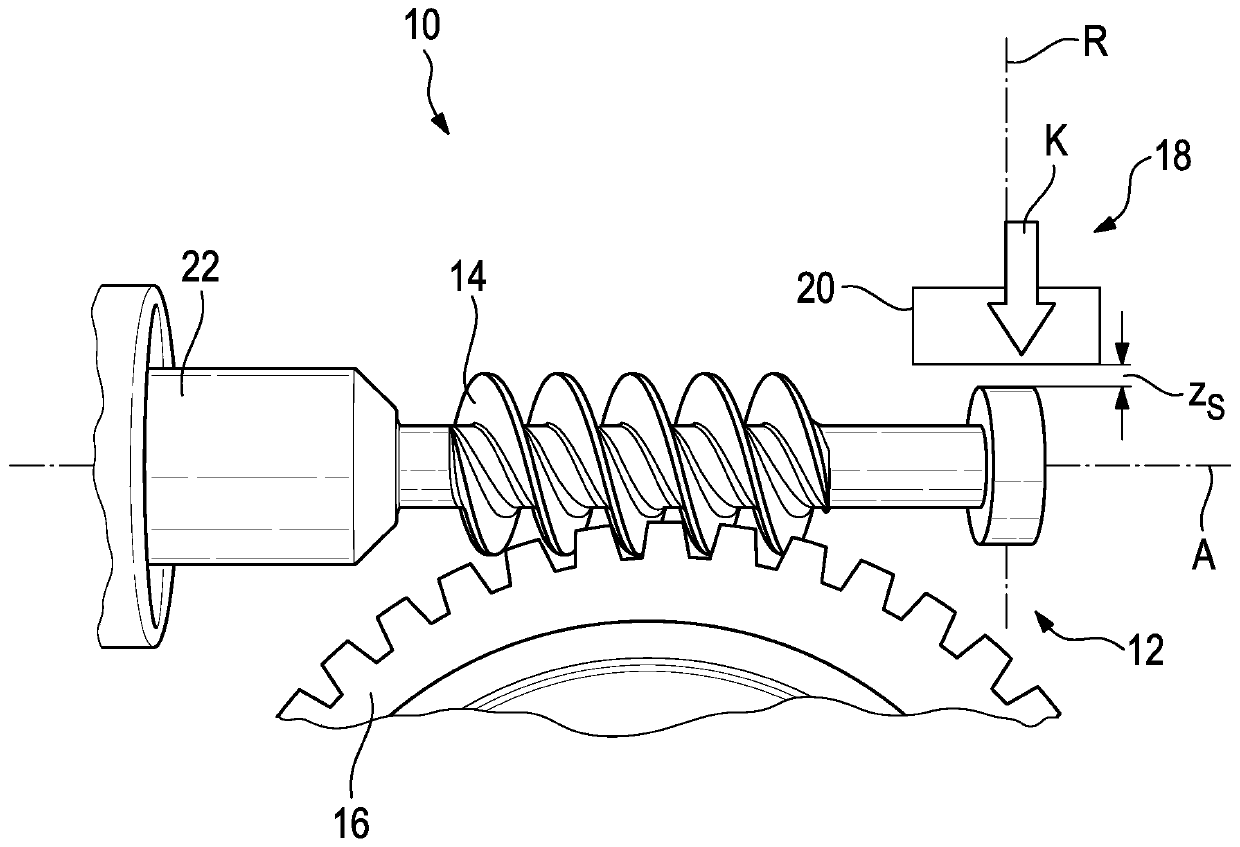

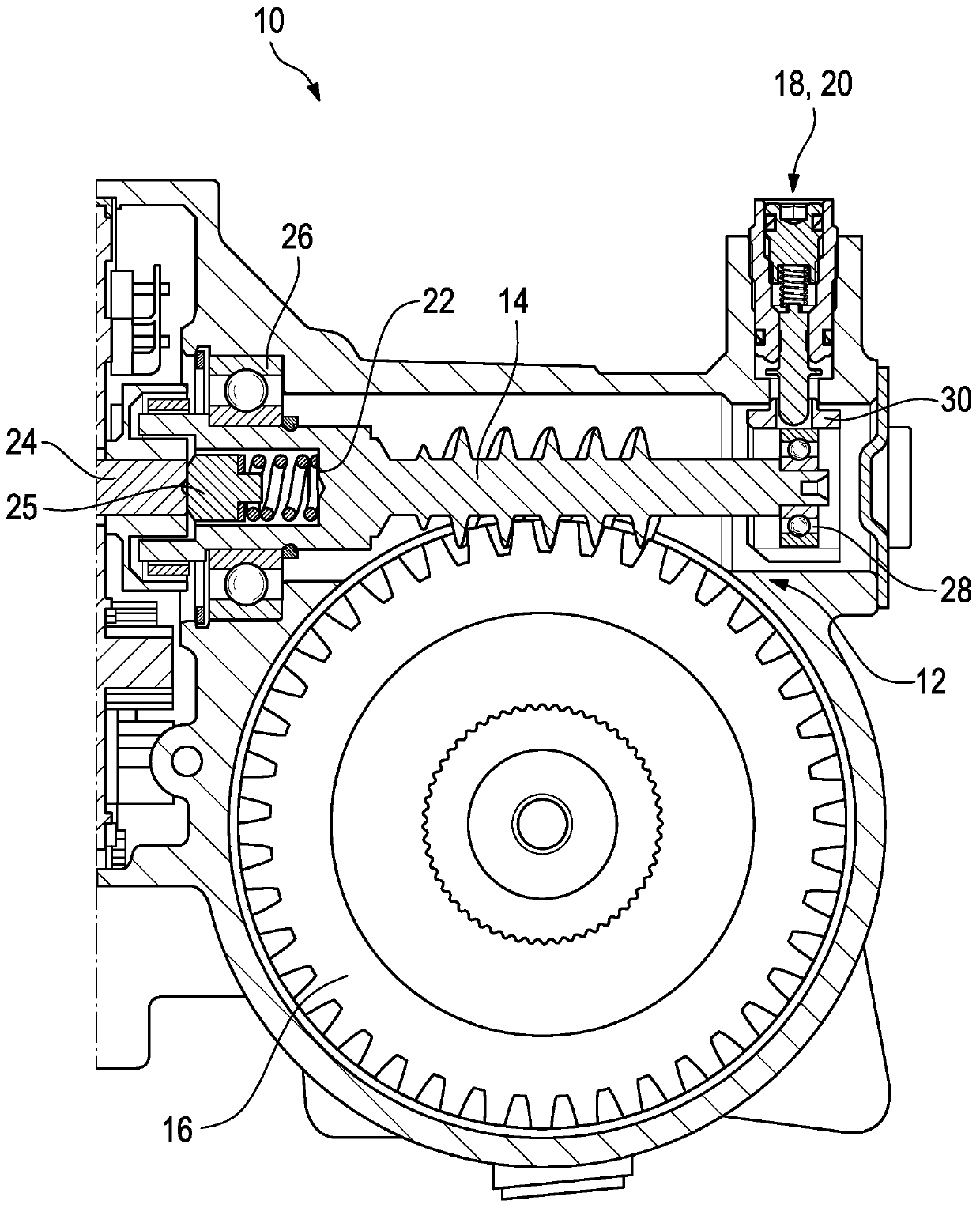

[0034] figure 1 A first variant of the electric power steering system 10 is schematically shown.

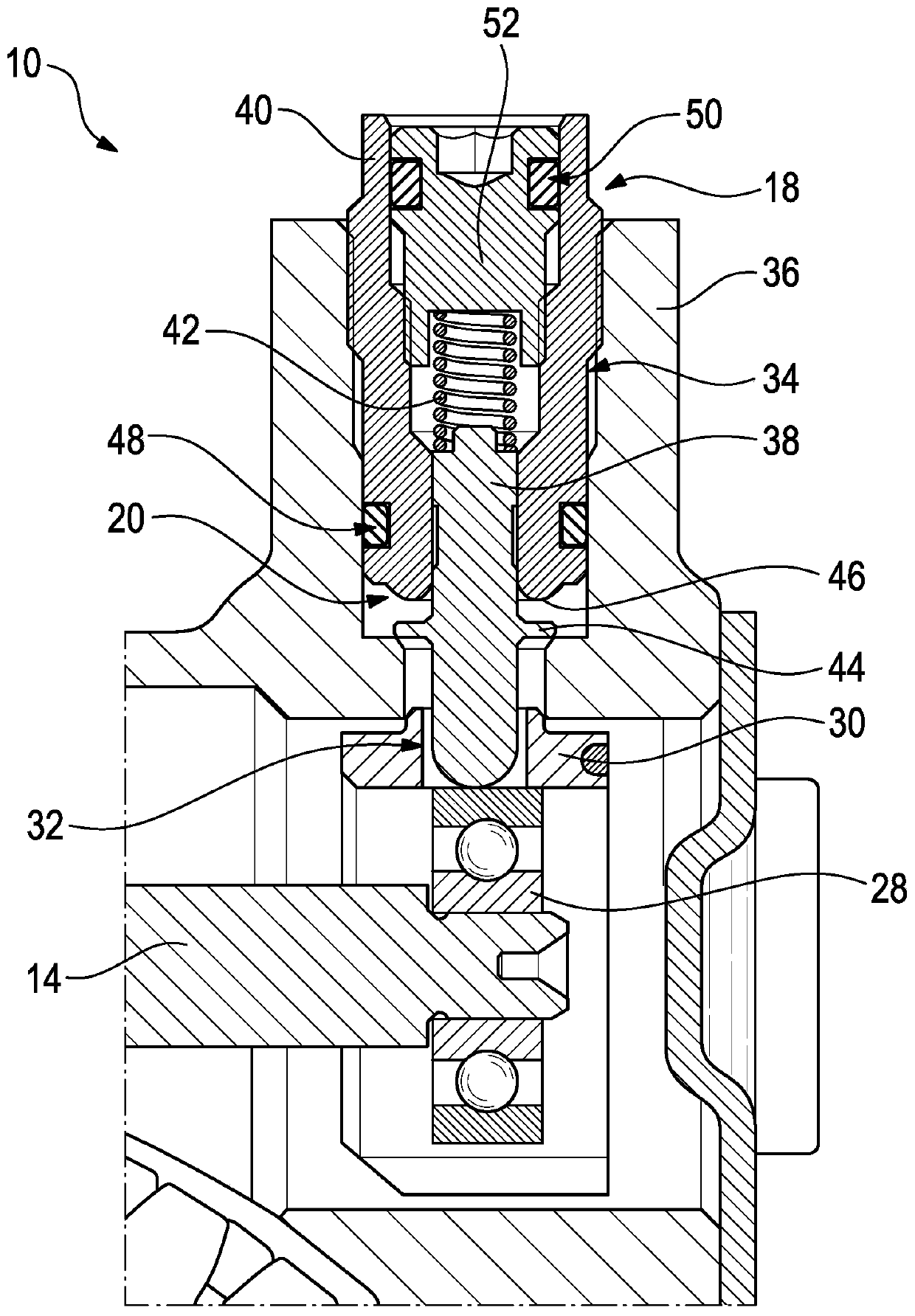

[0035] The steering system 10 includes a worm gear mechanism 12 with a worm shaft 14 and a worm wheel 16 , and also includes a pretensioning device 18 with a limiting device 20 .

[0036] The worm shaft 14 comprises an end 22 (not shown) associated with the electric motor, wherein the electric motor is force-transmittingly connected to the worm shaft 14 and thus also to the worm wheel 16 . The electric motor includes in particular an auxiliary motor of the steering system 10 .

[0037] The worm gear 16 is force-transmittingly coupled to a steering column or rack of the steering system 10 . Thus, this includes an electric power steering system 10 with a steering column drive or a rack and pinion drive.

[0038] exist figure 1 In , the basic operation of the steering system 10 has been indicated, more particularly in relation to the pretensioner 18 and the limiter 20 .

[0039] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com