Wall-mounted washing machine

A washing machine and wall-mounted technology, which is applied in the field of washing machines, can solve the problems of easy displacement of the motor, installation of the motor, and easy damage of the fixing hole, and achieve the effects of avoiding motor failure, simplifying assembly steps, and occupying a small space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

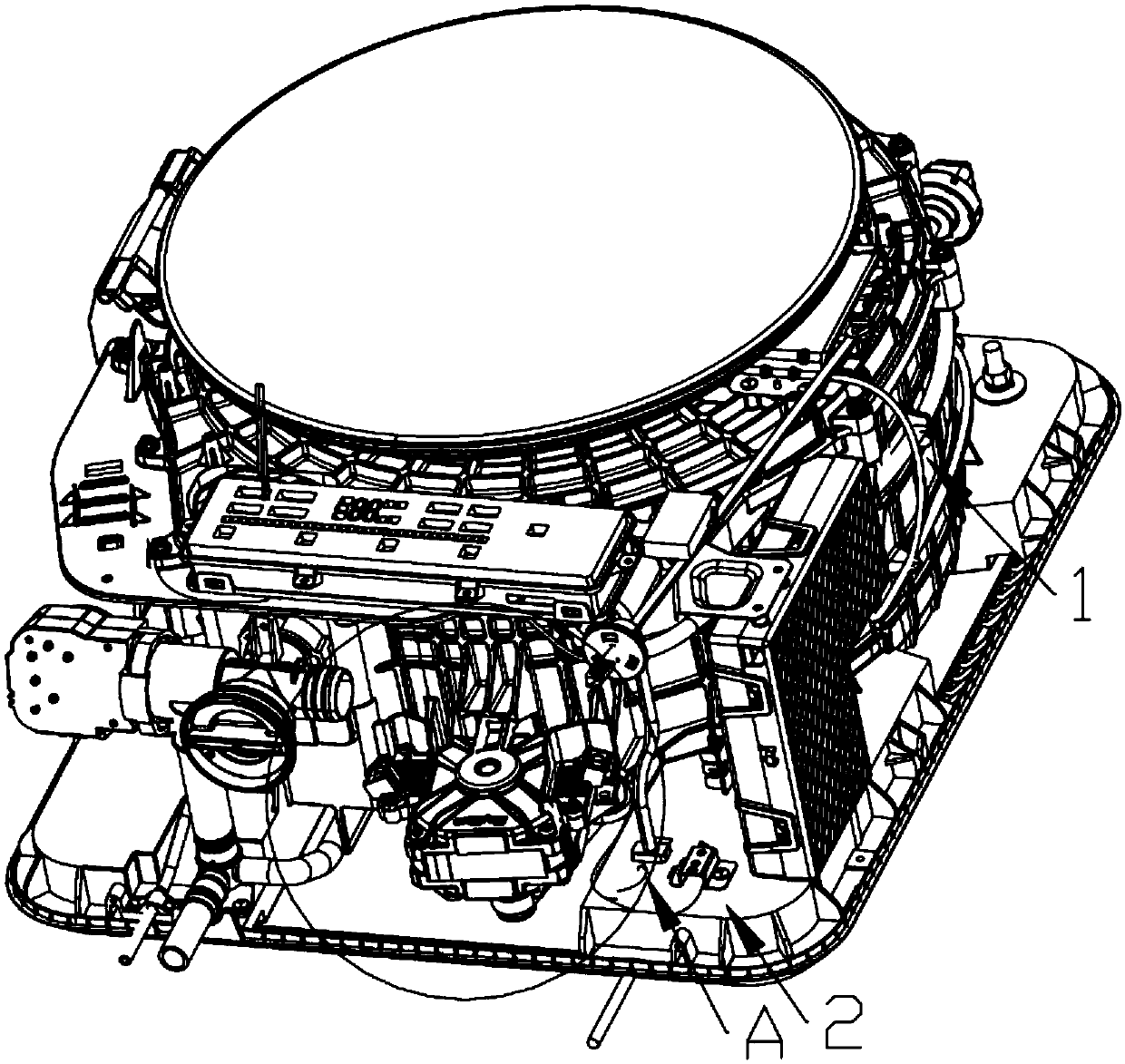

[0054] like Figure 1-6 As shown, this embodiment discloses a wall-mounted washing machine, comprising:

[0055] Outer cylinder 1;

[0056] an inner cylinder arranged in the outer cylinder 1;

[0057] The motor 4 that controls the rotation of the inner cylinder is suspended on the wall around the outer cylinder.

[0058] In the above solution, the motor 4 is suspended on the peripheral wall of the outer cylinder 1 without the need for a wall or a rear panel, has low requirements for other components, has a wide application range, a simpler structure, takes up less space, and is convenient and reliable for installation / disassembly. Wherein, the motor 4 transmission belt 6 suspended on the peripheral wall of the outer cylinder 1 is connected with the rotating disk 3 at the rear of the outer cylinder 1, and the rotating disk 3 is connected with the rotating shaft of the inner cylinder to control the rotation of the inner cylinder. In addition, the present invention improves th...

Embodiment 2

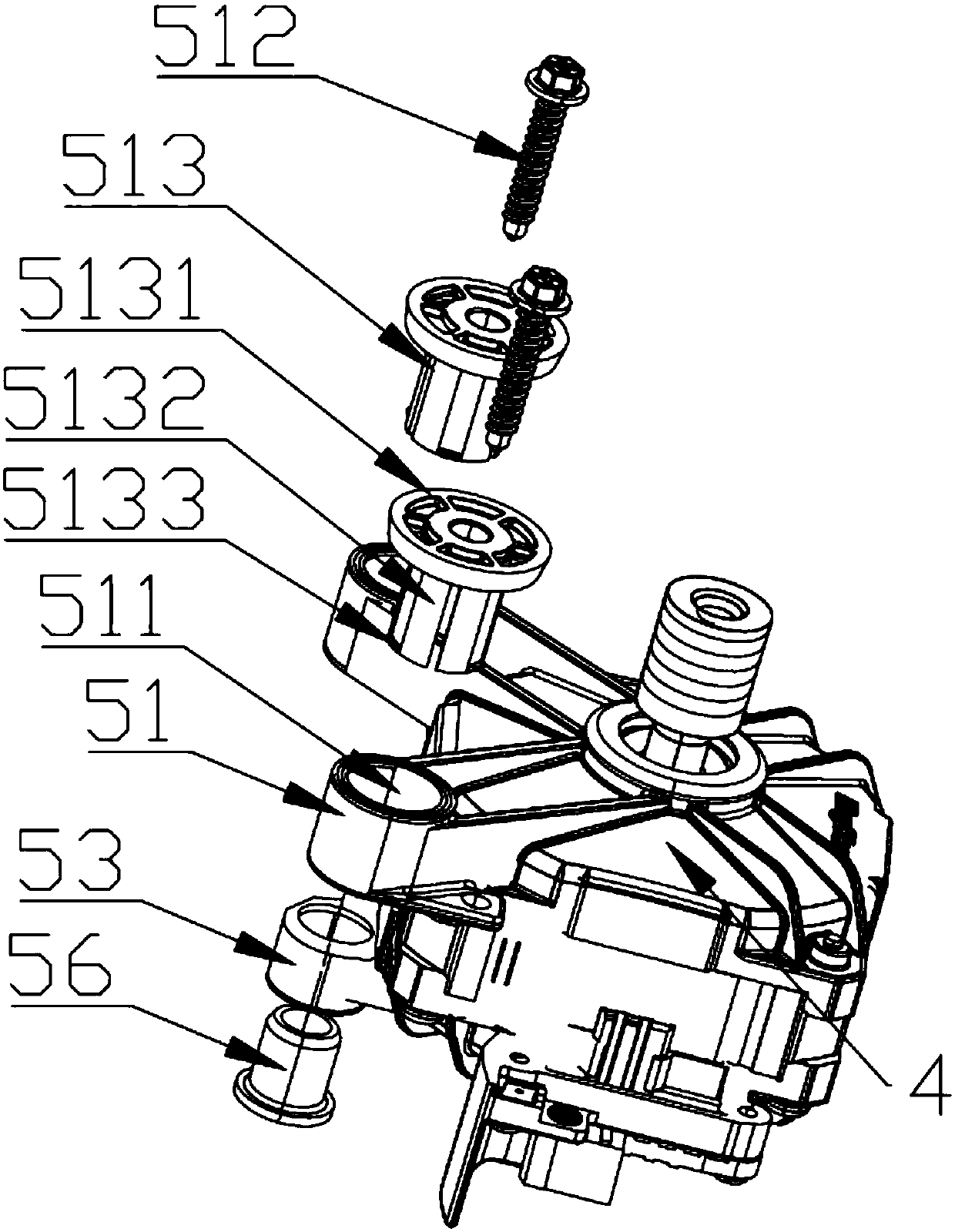

[0096] This embodiment discloses a wall-mounted washing machine. Compared with Embodiment 1, the difference is that the positioning and fixing part includes:

[0097] The first suspension part protrudes radially from the peripheral wall of the outer cylinder;

[0098] One end of the mounting column is connected to the first suspension part, and the other end extends toward the front of the outer cylinder along the axial direction of the outer cylinder.

[0099] Further, the position-limiting fixing part includes a third hanging part radially protruding from the peripheral wall of the outer cylinder and a fixing column, one end of the fixing column is connected to the third hanging part, and the other end of the fixing column extends toward the outer cylinder along the axial direction of the outer cylinder. Front extension.

[0100] In the above solution, the motor is suspended on the peripheral wall of the outer cylinder, and since the direction of the installation column ext...

Embodiment 3

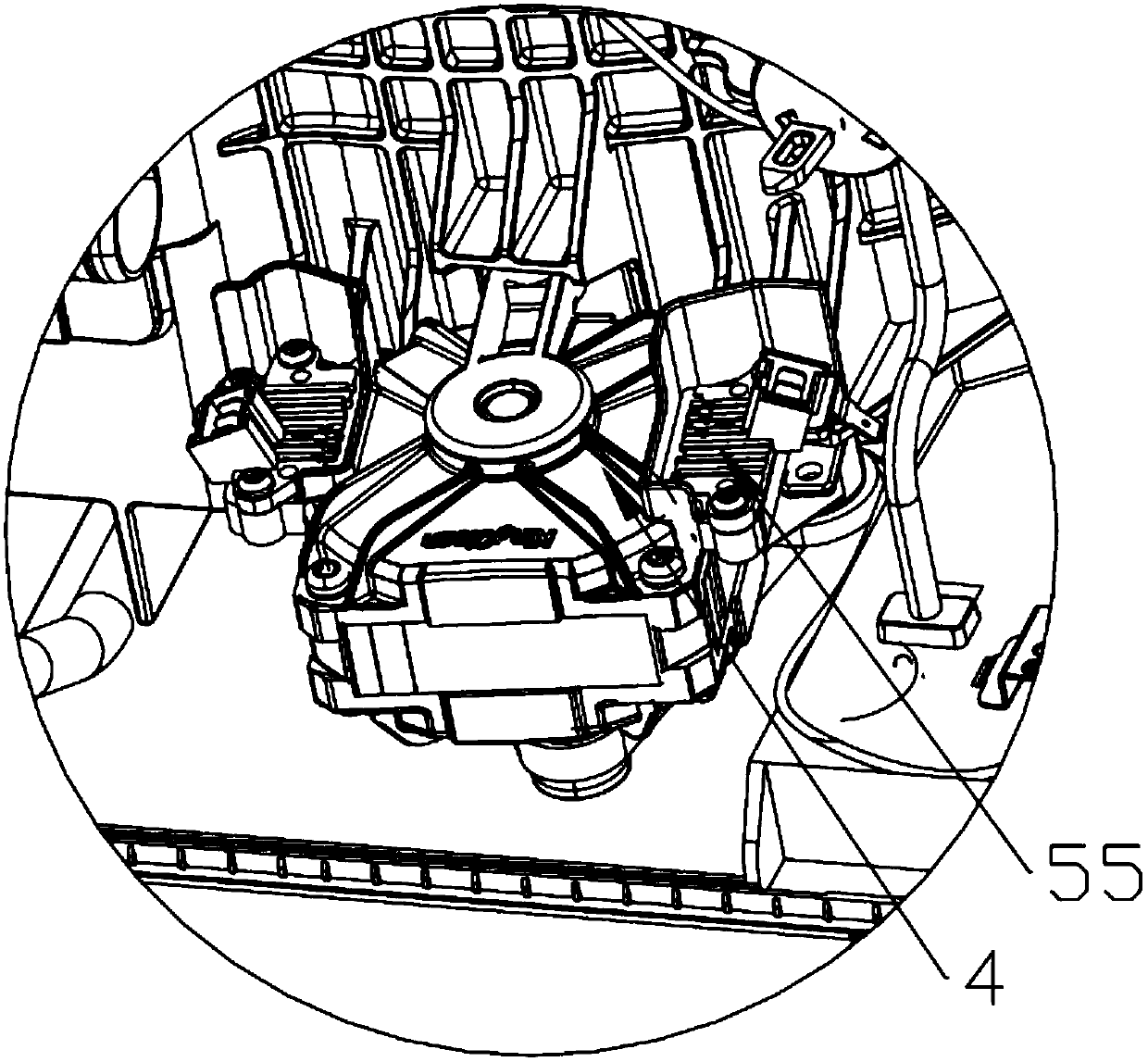

[0102] like Figure 1-6 As shown, this embodiment introduces a wall-mounted washing machine, which includes an outer cylinder 1 directly mounted on the wall, and a rotatable inner cylinder sleeved in the outer cylinder 1, and also includes a turntable 3, the turntable 3 is set On the rear side of the outer cylinder 1, it is connected to the rotating shaft of the inner cylinder; the motor 4, the output shaft of the motor 4 is connected to the turntable 3 through the transmission belt 6; the installation structure 5 is configured to detachably connect the motor 4 to the outer cylinder 1 on the end near the wall.

[0103] In the present invention, by directly assembling the outer cylinder 1 on the wall, the assembly structure between the outer cylinder 1 and the wall is omitted, and no rear panel is provided, which reduces the production and transportation costs of the washing machine, and simplifies the assembly steps of the washing machine at the same time. The difficulty of a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com