Vacuum drainage electroless mechanical micro-air pressure opening structure and use method thereof

A technology of vacuum drainage and micro-air pressure, which is applied in the direction of mechanical equipment, engine components, valve details, etc., can solve the problems of power consumption, leakage, equipment rust, etc., and achieve the effect of wide promotion and application, small trigger air pressure and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

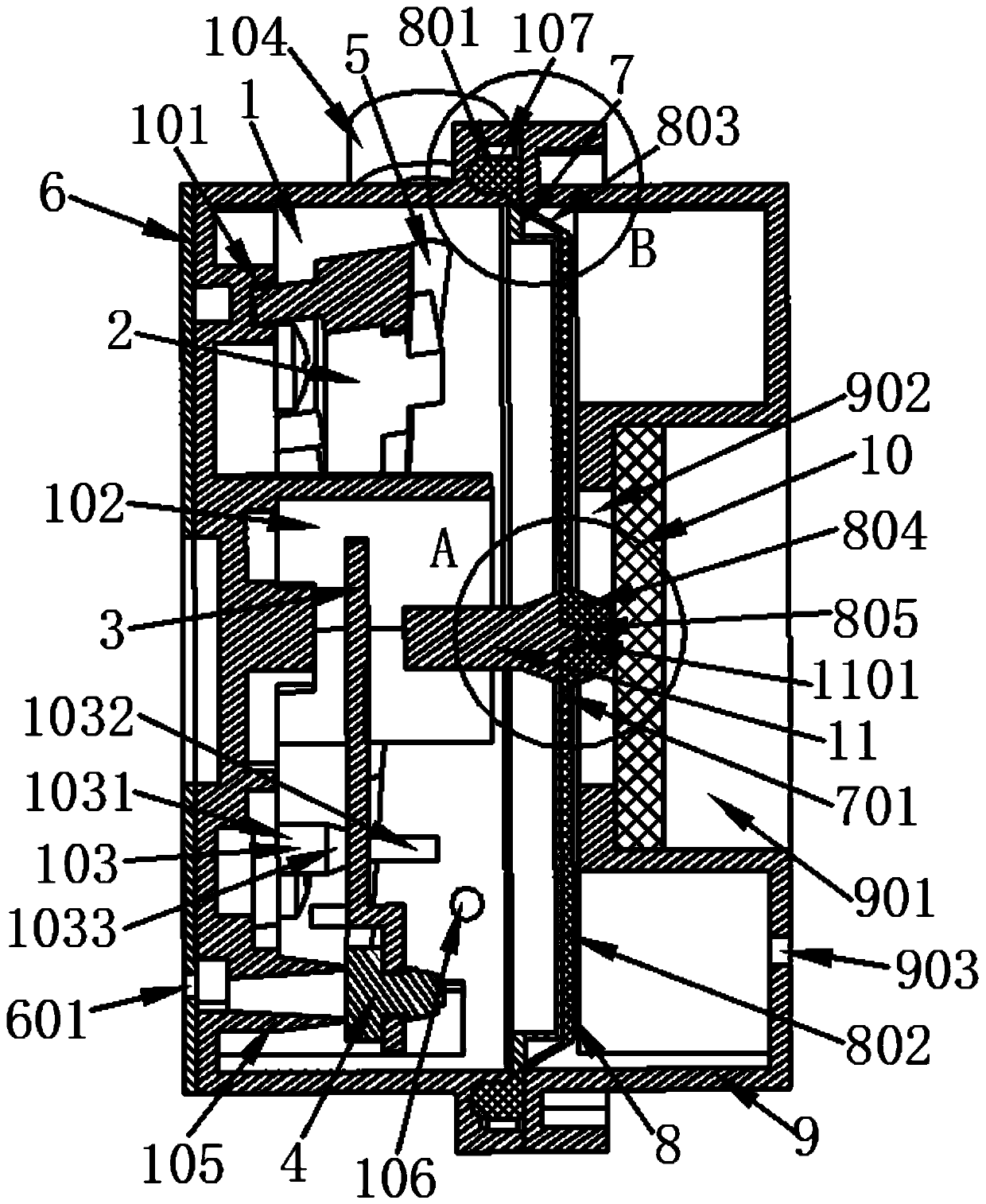

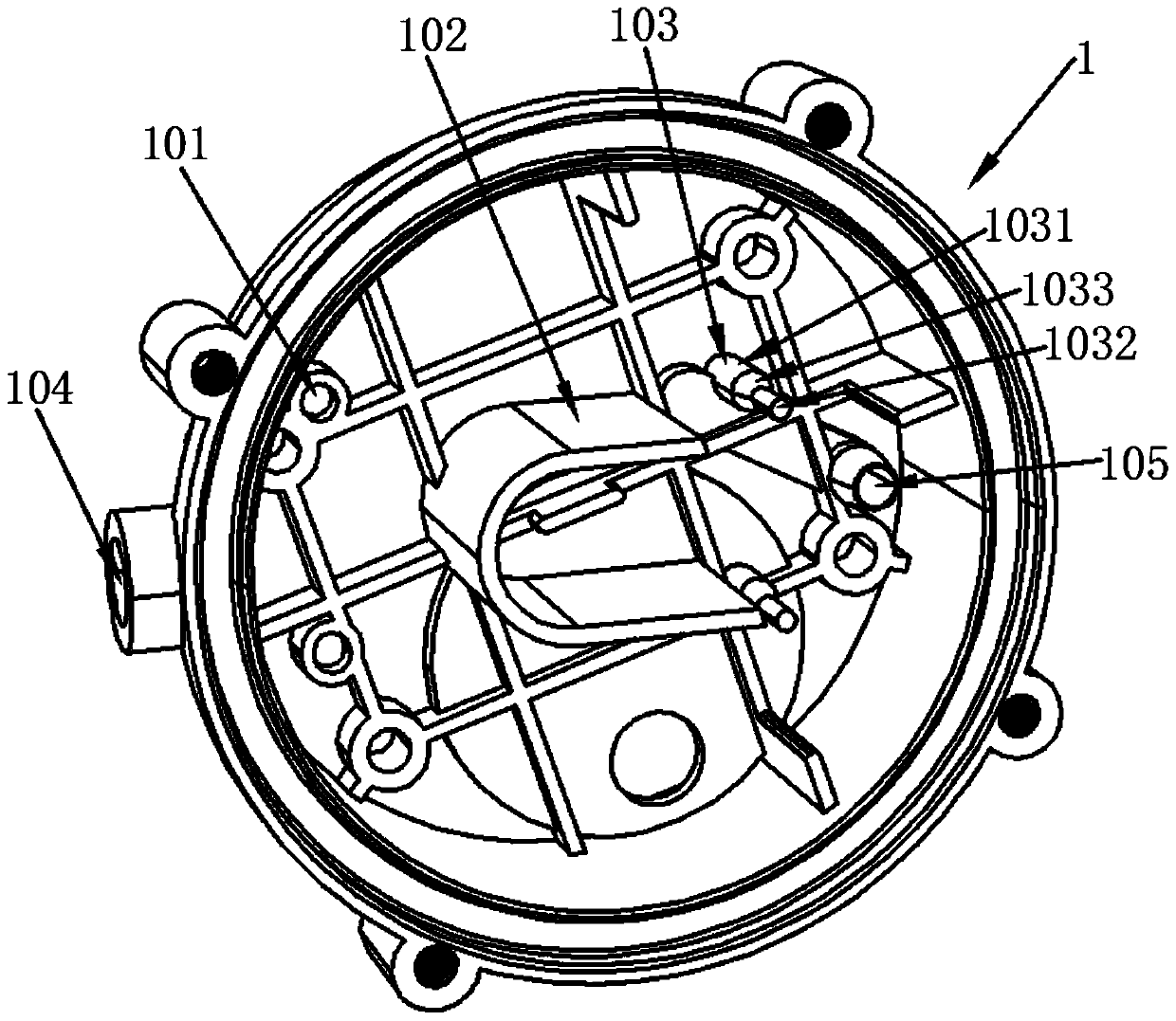

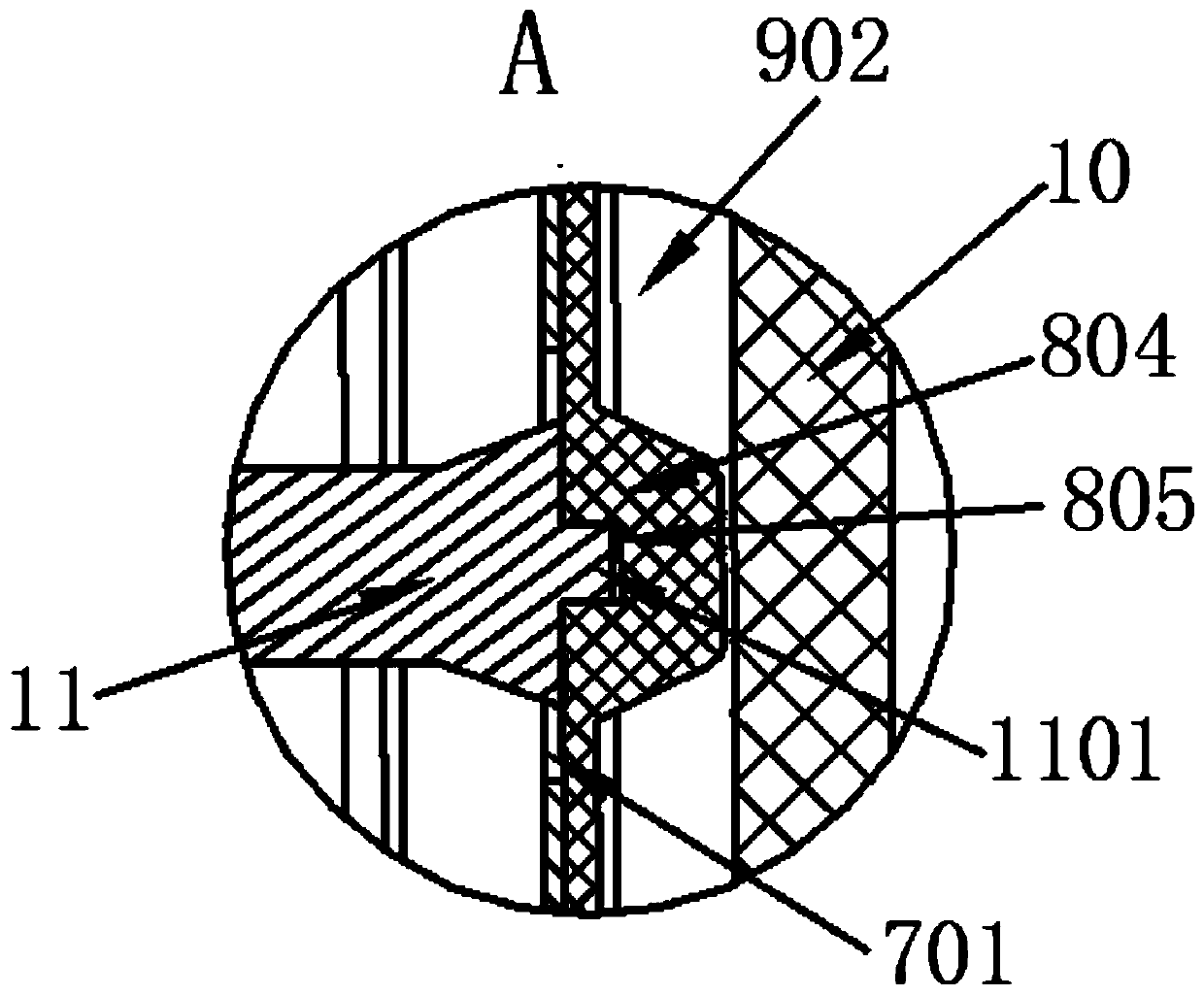

[0032] refer to Figure 1-Figure 9 , a vacuum drainage non-electric mechanical micro-pressure opening structure and its use method of the present invention, comprising a main housing 1, a U-shaped pressing plate 2, a Z-shaped seesaw 3, a rubber block 4, a reset push rod 5, a top cover 6, a support Plate 7, rubber membrane 8, fixed cover 9, rubber blocking plate 10 and working column 11, the main housing 1 is provided with a circular groove 101, a U-shaped baffle 102 and a central pillar 103, the circular groove 101 and the number of middle pillars 103 are two, the circular groove 101 and the middle pillar 103 are respectively located on both sides of the U-shaped baffle plate 102, the main housing 1 is also provided with a tapered tube 105, and the lower part of the tapered tube 105 is a cylinder 1031 is connected with the upper upper cylinder 1032 of the tapered pipe 105 through a conical inclined surface 1033, a small circular hole 104 is provided on the outside of the side ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com