LED display module lamp seam glue pouring process

A display module and glue filling technology, which is applied in the direction of instruments, identification devices, etc., can solve the problems that it is difficult to achieve the protective effect of lamp beads, the efficiency of glue filling is low, and the fluidity of glue is poor, so as to achieve thick glue filling and flow Good performance and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

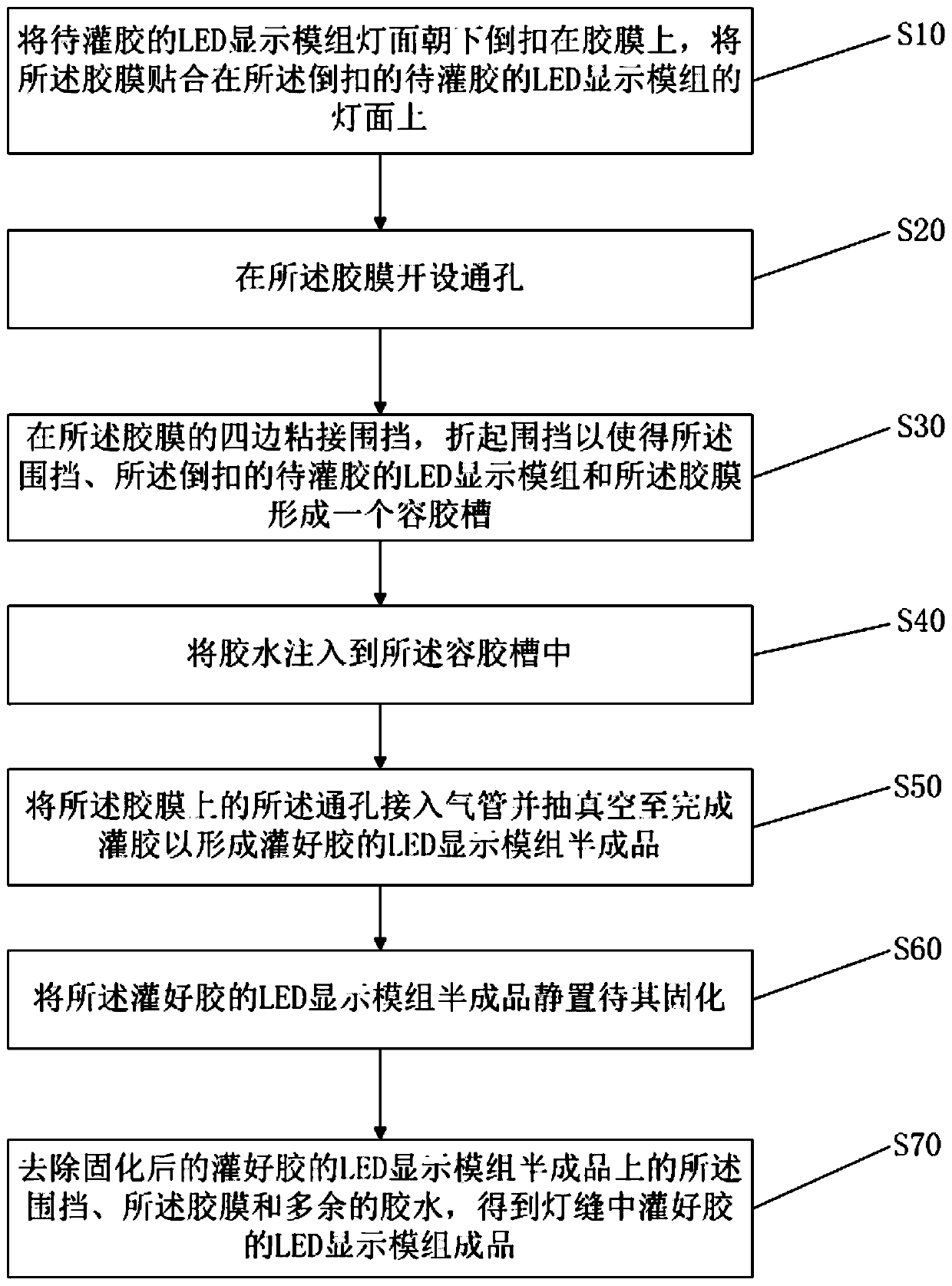

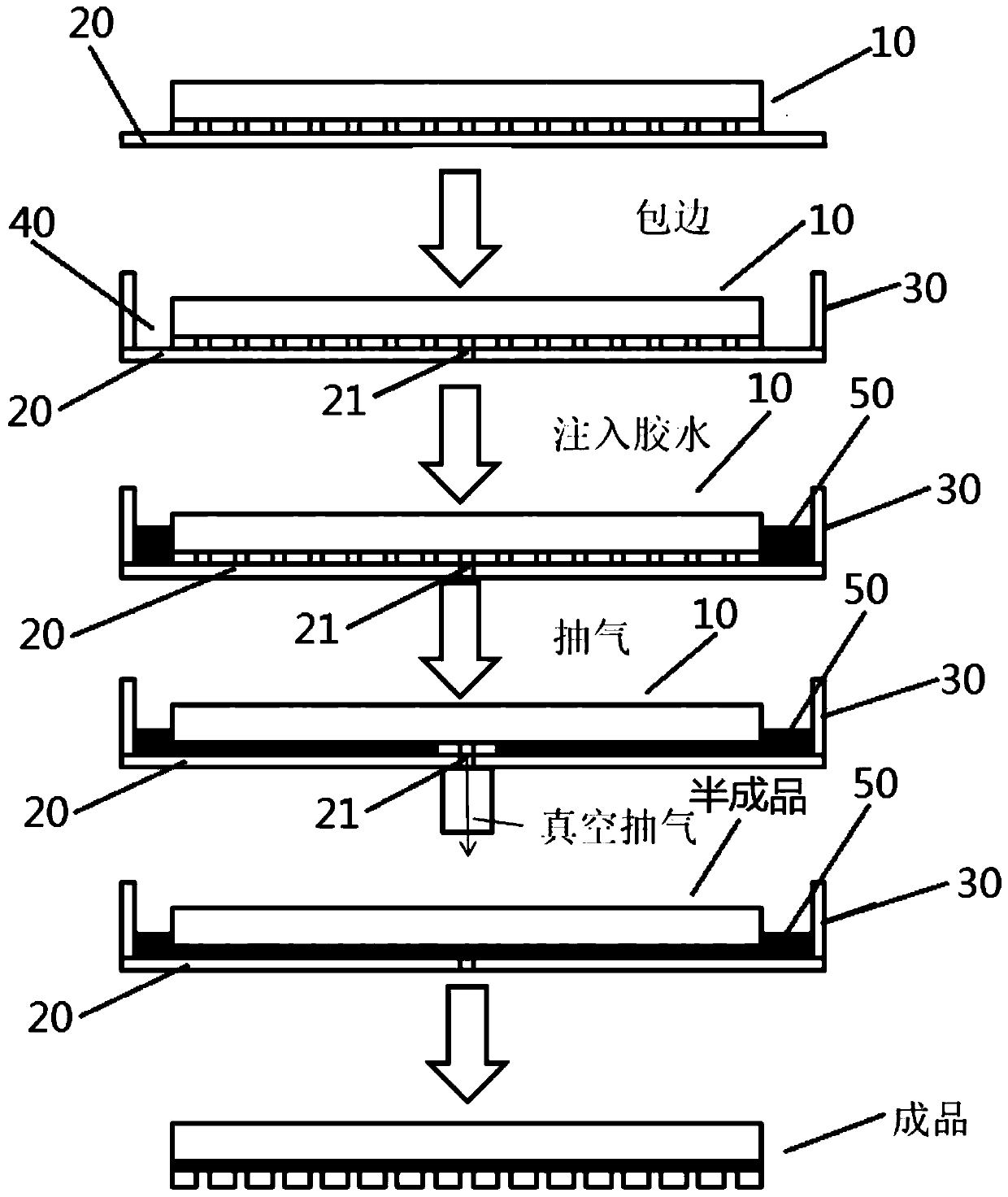

[0040] combine figure 1 with figure 2 As shown, a LED display module lamp seam glue filling process in this embodiment includes the following steps:

[0041] Step S10, the LED display module 10 to be glued is turned upside down on the adhesive film 20, and the adhesive film 20 is pasted on the turned-down LED display module 10 to be glued. face.

[0042] Specifically, prepare an adhesive film 20 with a certain viscosity and can be removed later and the LED display module 10 to be glued, spread the adhesive film 20 flat, and then place the LED display module 10 to be glued face down On the flat adhesive film 20, the adhesive film 20 is pasted on the lamp surface of the LED display module 10 to be glued upside down, and the stickiness of the adhesive film 20 can be used directly, or Auxiliary other means such as heat pressing. As an optimization, after the LED display module 10 to be glued is buckled upside down on the adhesive film 20 , the distance between each side of th...

Embodiment 2

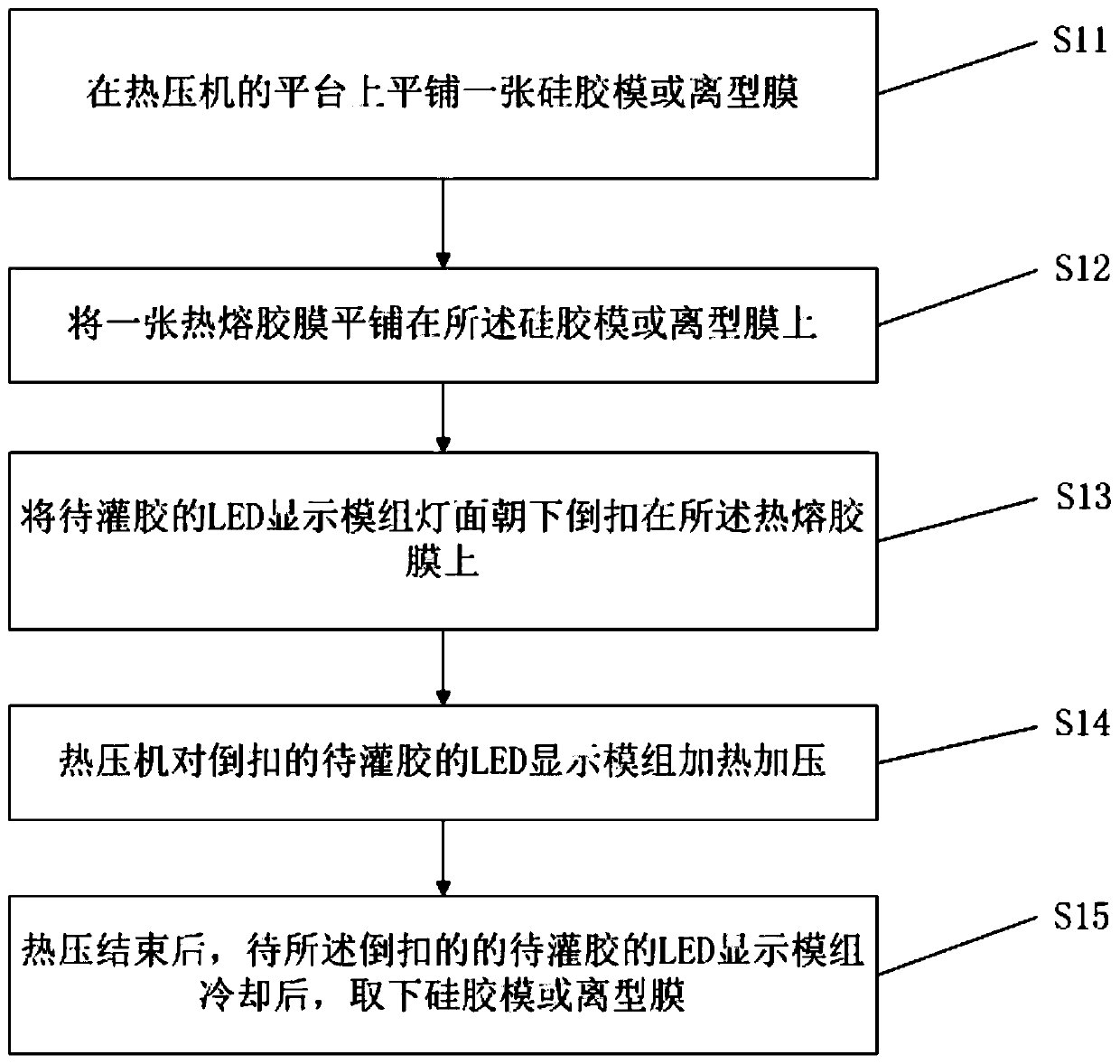

[0057] The difference between this embodiment and the first embodiment is that the adhesive film in this embodiment is a hot-melt adhesive film, which is pasted on the lamp surface of the LED display module to be glued by hot pressing.

[0058] In step S10 of the first embodiment, the lamp surface of the LED display module to be glued is turned upside down on the adhesive film, and the adhesive film is pasted on the lamp surface of the LED display module to be glued. Such as image 3 with Figure 4 As shown, in this embodiment include:

[0059] Step S11, spread a silicone mold or release film 100 on the platform of the heat press machine.

[0060] Concretely, lay a piece of silicone mold or release film 100 on the hot press platform of the hot press. on the platform.

[0061] Step S12 , spreading a piece of hot melt adhesive film 20 on the silicone mold or release film 100 .

[0062] Specifically, a piece of hot-melt adhesive film 20 is spread flat on the silicone mold or...

Embodiment 3

[0071] The difference between this embodiment and embodiment one is that the composition of the sol tank is different, such as Figure 5 As shown, the LED display module lamp seam glue filling process in this embodiment includes the following steps:

[0072] Step S100 , turning the LED display module lamp to be glued face down on the adhesive film, and attaching the adhesive film to the lamp surface of the LED display module to be glued upside down.

[0073] Step S200, opening a through hole on the adhesive film.

[0074] Step S300, buckle the LED display module to be glued with the adhesive film upside down, with the adhesive film facing downwards, into a glue potting jig, and the glued upside down LED display module to be filled with the adhesive film The outer sides of the glued LED display module and the inner sides of the glue potting jig form a glue-holding groove.

[0075] Specifically, prepare a glue filling jig, put the LED display module to be glued with the glued ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com