Movable spring structure capable of preventing breakage and mis-connection and electromagnetic relay

An electromagnetic relay, misconnection technology, applied in electromagnetic relays, electromagnetic relay details, relays, etc., can solve the problems of misconnection of the static spring part, affecting the safety of the relay, tilting and falling, etc., to improve safety, Easy assembly, avoid deformation or breakage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

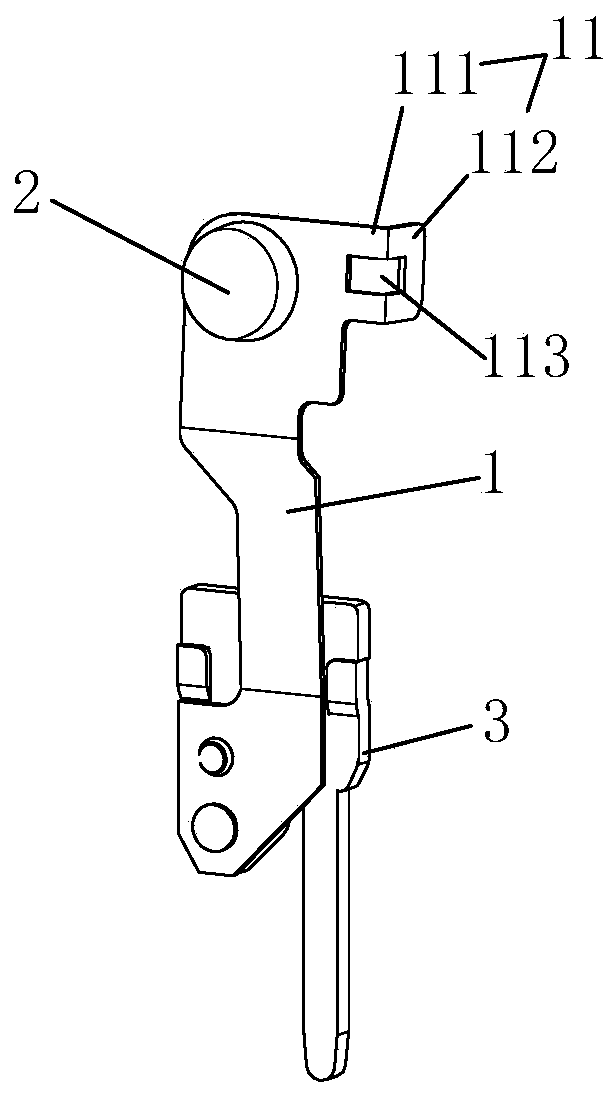

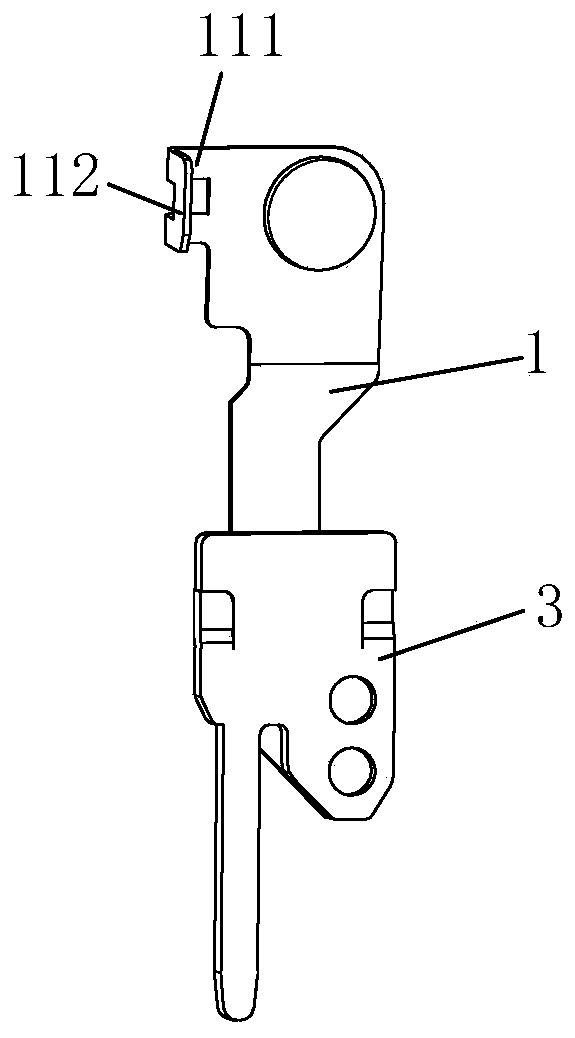

[0031] Example 1, please refer to figure 1 , figure 2 As shown, a kind of moving spring structure of the present invention to prevent breakage and mistaken connection is used for relays, including a moving reed 1, and the head of the moving reed 1 is provided with a moving contact 2; the head of the moving reed 1 is provided with a Hang on the L-shaped hooking portion 11 on the push card of the relay, and the L-shaped hooking portion 11 includes one side along the width direction of the moving reed 1 (the side can be any direction in the width direction of the moving reed 1). The first extension part 111 extends from the first extension part 111 to the side where one side of the moving reed 1 is located.

[0032] In this embodiment, the number of the L-shaped hooking portion 11 is one, and the second extension portion 112 of the L-shaped hooking portion 11 is located on opposite sides of the moving reed 1 to the movable contact 2 . The L-shaped hooking portion 11 defines a...

Embodiment 2

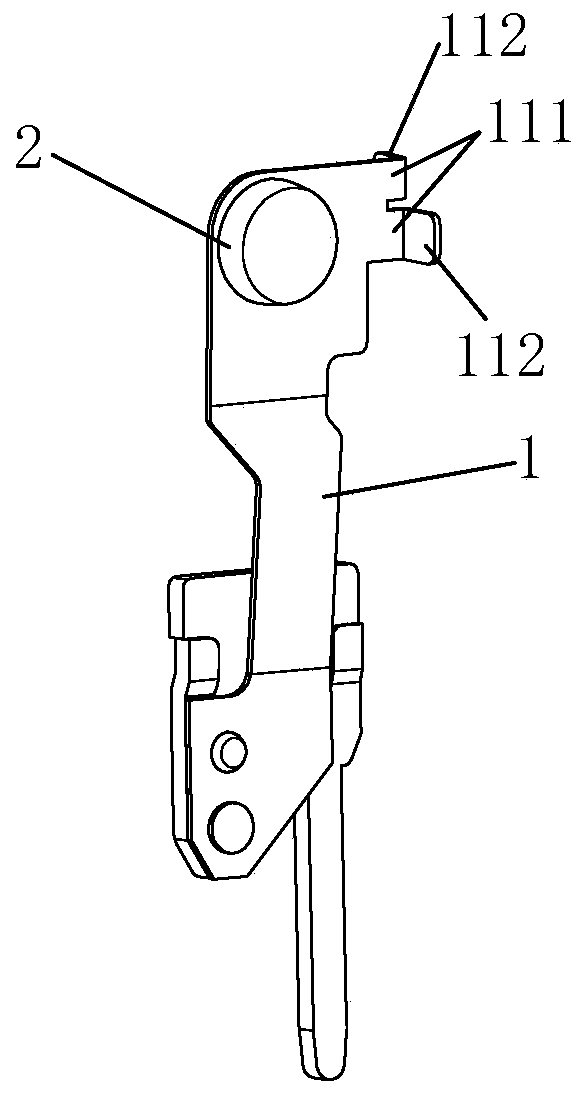

[0036] See image 3 , Figure 4As shown, the moving spring structure of the present invention to prevent breakage and mistaken connection differs from the first embodiment above in that: the number of the L-shaped hooking parts 11 is two, and the two L-shaped hooking parts 11 are located on the same side of the moving reed 1 and distributed up and down, and the second extensions 112 of the two L-shaped hooking parts 11 are located on opposite sides of the moving reed 1 .

[0037] See Figure 5-Figure 10 As shown, an electromagnetic relay of the present invention includes a base 10, and a magnetic circuit part 20, a moving spring part, and a static spring part arranged on the base 10. The magnetic circuit part 20 is connected and matched with the moving spring part through a push card 30. , The moving spring part corresponds to the static spring part. The moving spring part adopts the moving spring structure described in the above-mentioned embodiment 1 or embodiment 2 to pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com