Wire stabilizing and stripping machine

A wire stripping machine and wire stabilizing technology, which is applied in the direction of cable installation devices, electrical components, equipment for dismantling/armoring cables, etc., can solve the problems of cable deviation from the blade, difficulty in cutting wires, and failure of the cable to align with the blade, etc., to achieve The effect of promoting deviation and preventing deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings.

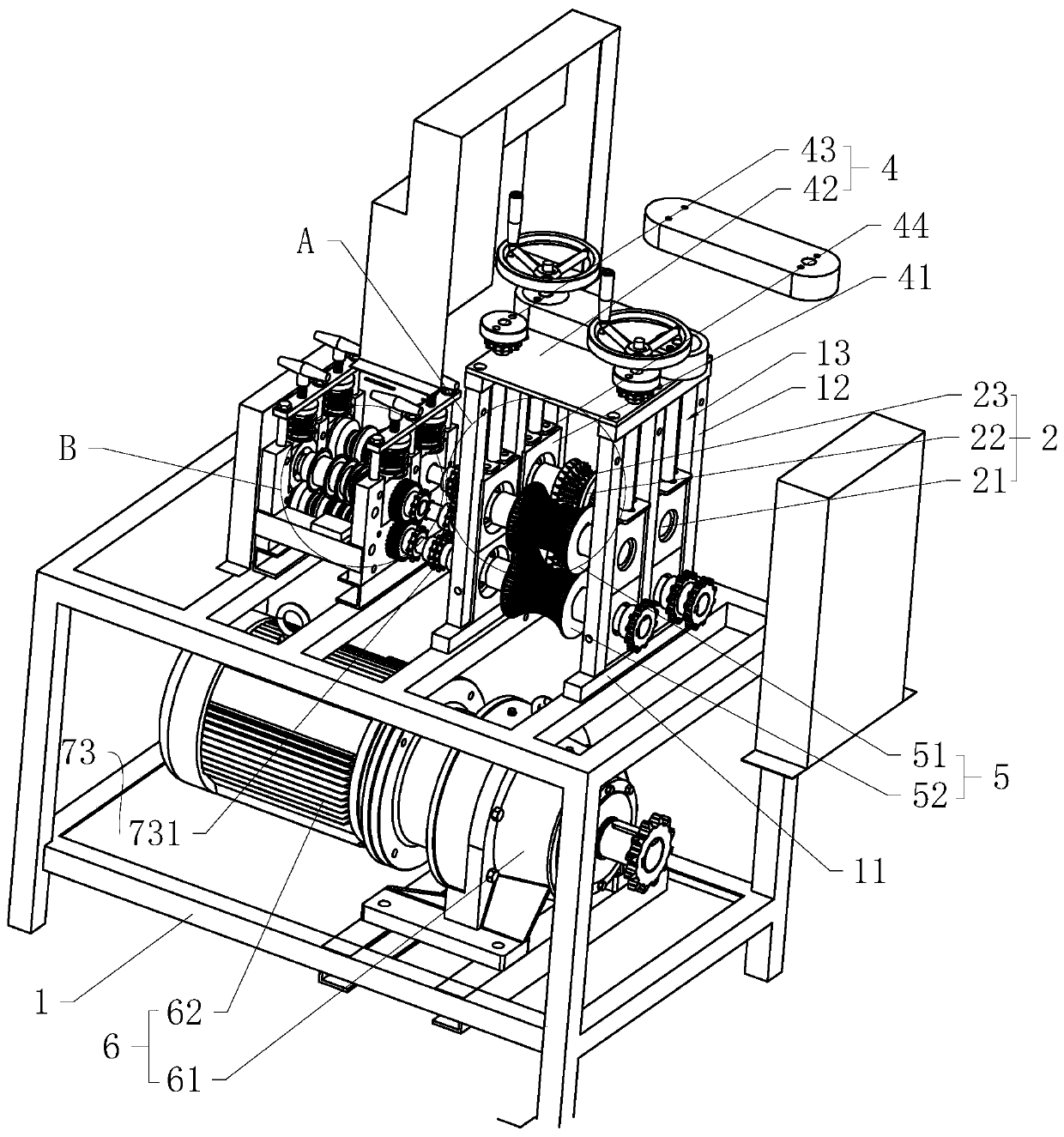

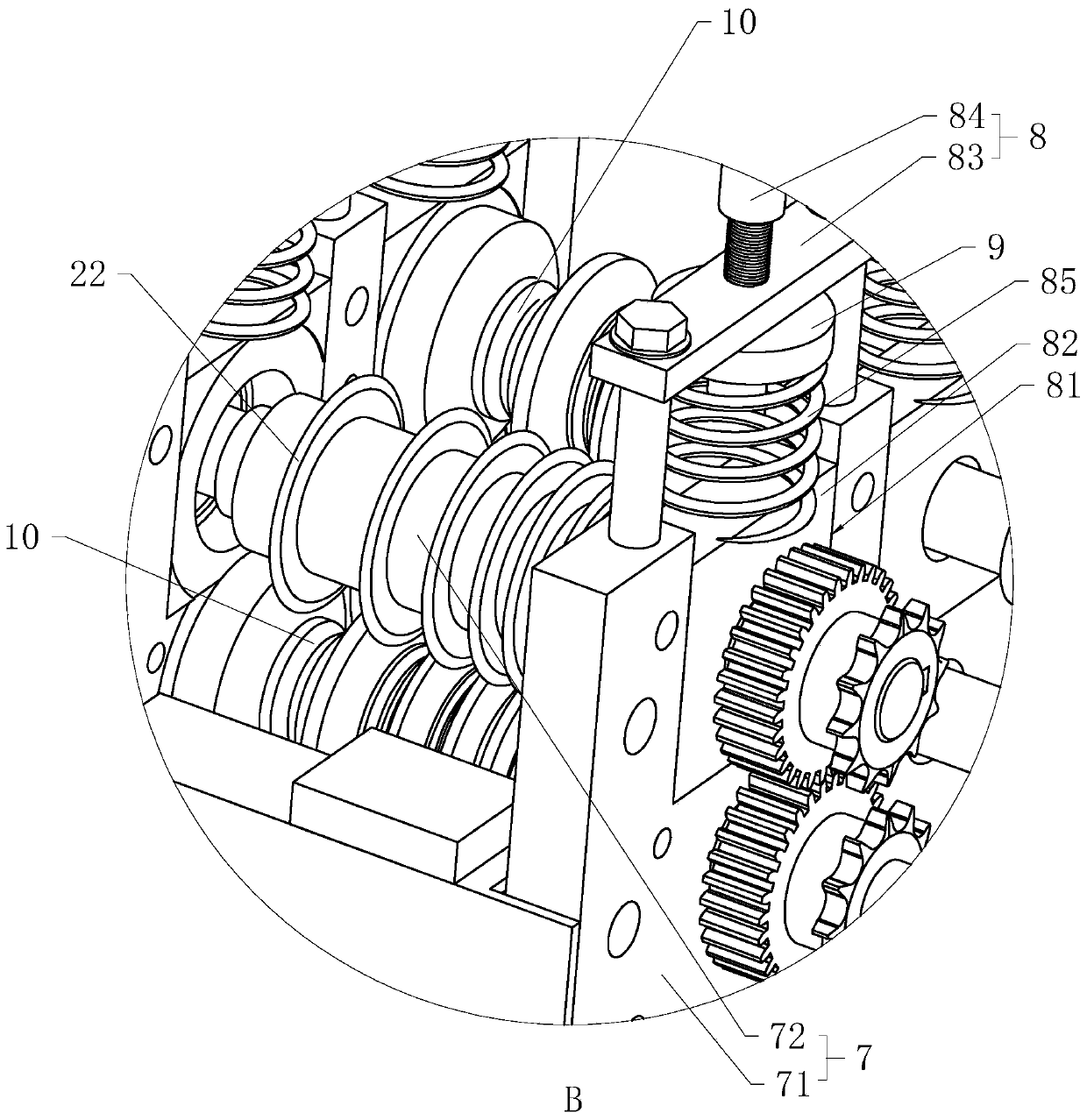

[0034] like figure 1 As shown, a wire-stabilizing stripping machine includes a bracket 1, an upper nip roller 2, a lower nip roller 3, a wire-stabilizing mechanism 5, and a driving mechanism 6. The bracket 1 is used as a supporting body on which two installations opposite to each other are fixed. Each mounting frame 11 has three uprights 12, and an installation space 13 is formed between two adjacent uprights 12.

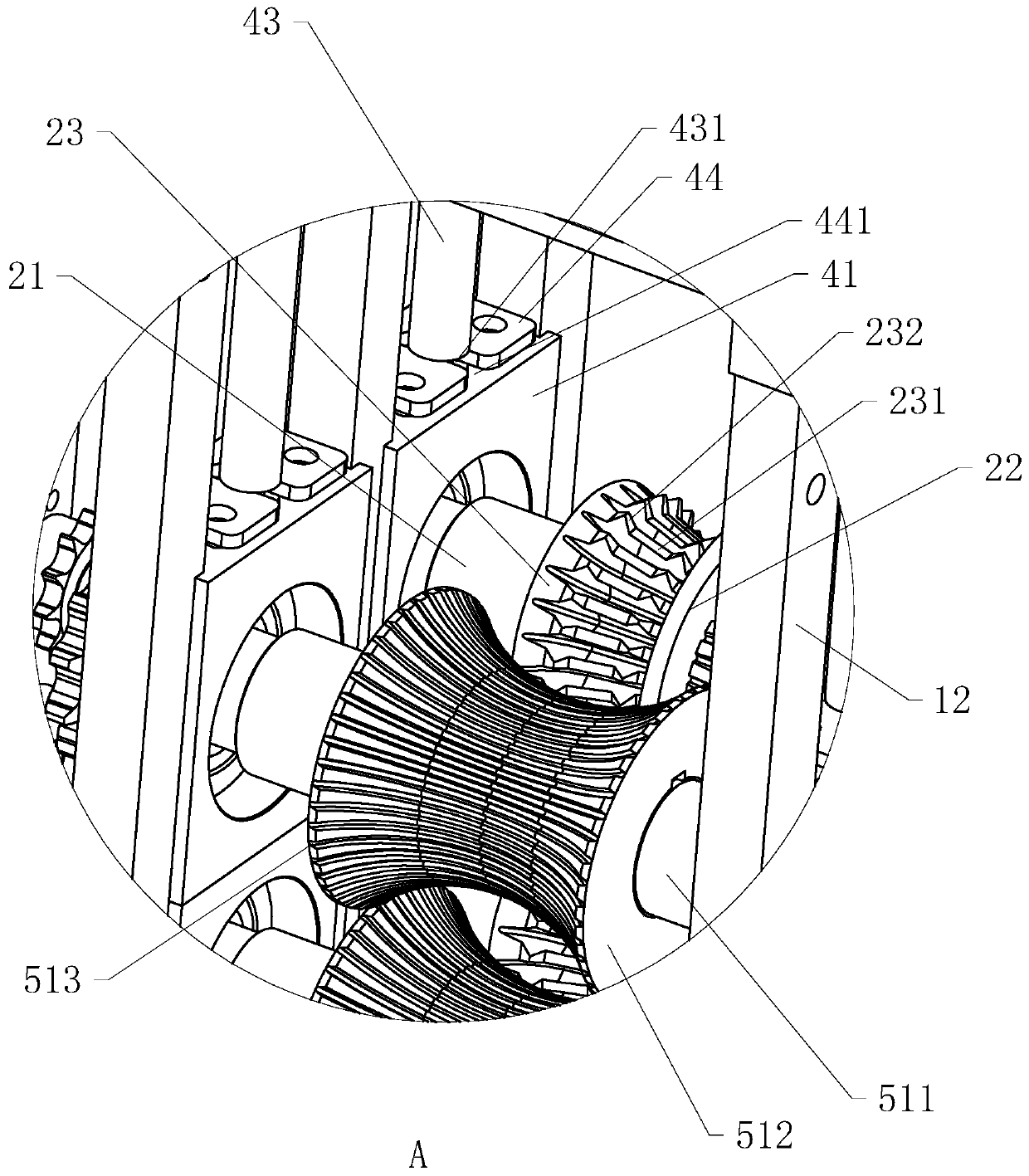

[0035] like figure 2 As shown, the upper nip roller 2 and the lower nip roller 3 have the same structure, both of which include a rotating shaft 21, a blade 22, and an alignment wheel 23, and the rotating shaft 21 is in the shape of a round stick; the blade 22 is sleeved on the rotating shaft 21, And it is located at the center of the rotating shaft 21, and the section of the through hole in the center of the blade 22 for cooperating with the ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com