Automobile brake pad drilling machine with drilling tool monitoring function

A technology for drilling machines and brake pads, which is applied in the direction of drilling/drilling equipment, boring/drilling, metal processing equipment, etc., to achieve the effect of stabilizing production efficiency and product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

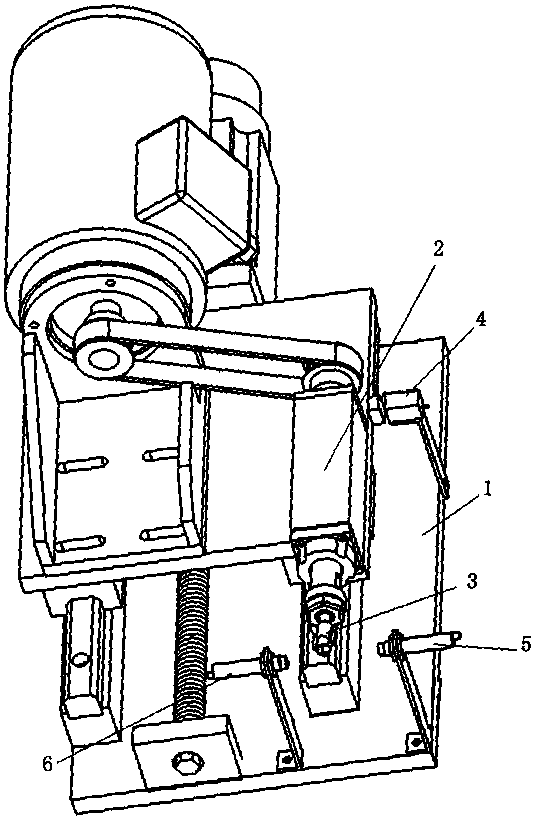

[0009] figure 1 Shown: above the base 1 of the drilling machine, a proximity switch 4 for monitoring the running state of the drilling machine feeding shaft 2 is installed on the outer side of the drilling machine feeding shaft 2, and the proximity switch 4 placed on the drilling machine feeding shaft 2 shaft head A photoelectric transmitter 5 for monitoring the drill bit 3 and a corresponding photoelectric receiver 6 are respectively installed on both sides of the drill bit 3 , and the built-in circuit of the photoelectric transmitter 5 communicates with the proximity switch 4 .

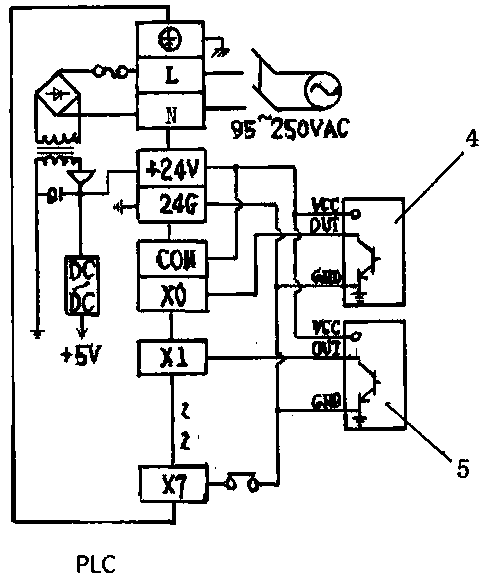

[0010] figure 2 As shown: the proximity switch 4 is connected to the photoelectric transmitter 5, so that the whole can run automatically. When the whole equipment stops running, it can automatically disconnect the power supply and close the monitoring operation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com