A foam molding machine and heating method using electromagnetic wave heating

A foamed plastic and electromagnetic wave technology, applied in the field of foamed plastic products, can solve the problems of large heat loss, waste water generation, environmental protection and energy saving, etc., to reduce large cells, refine cells, improve processing efficiency and controllability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

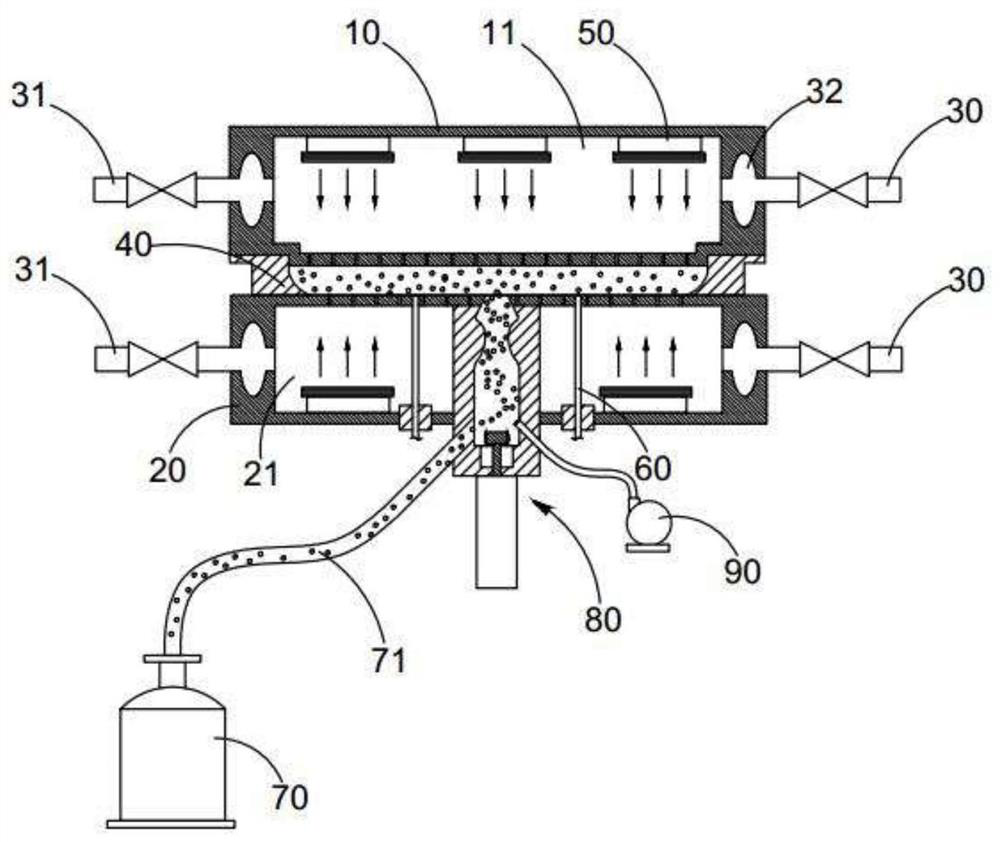

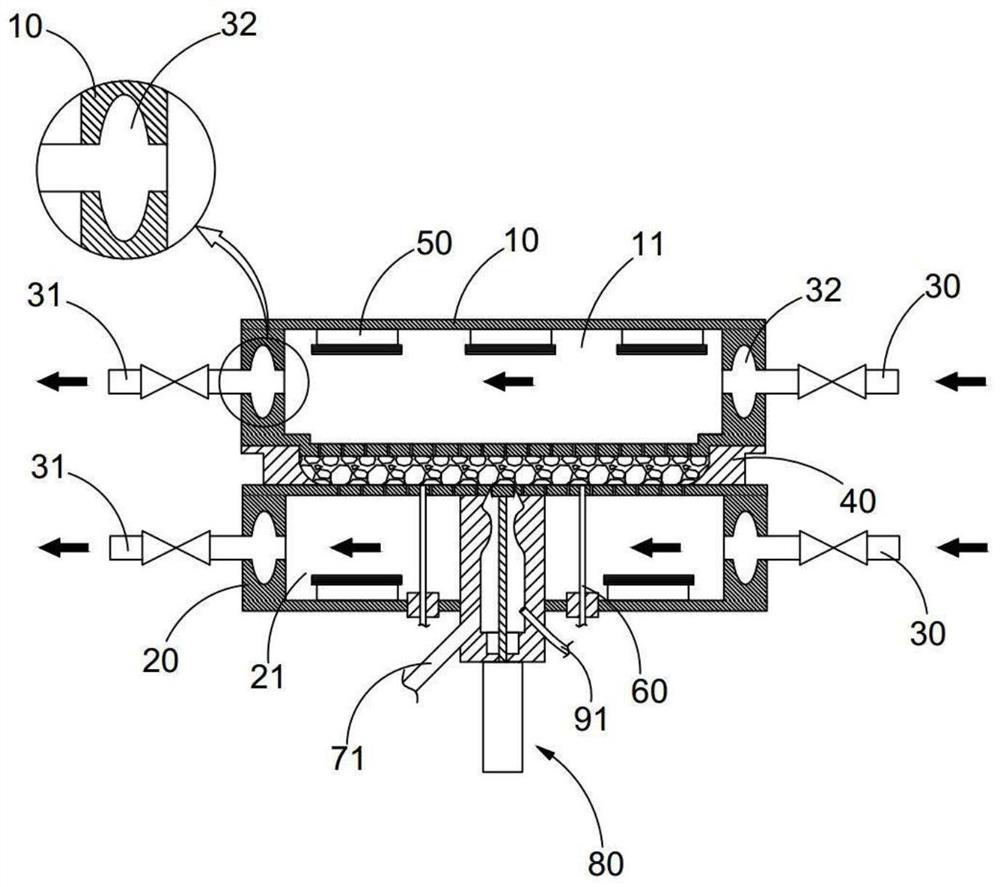

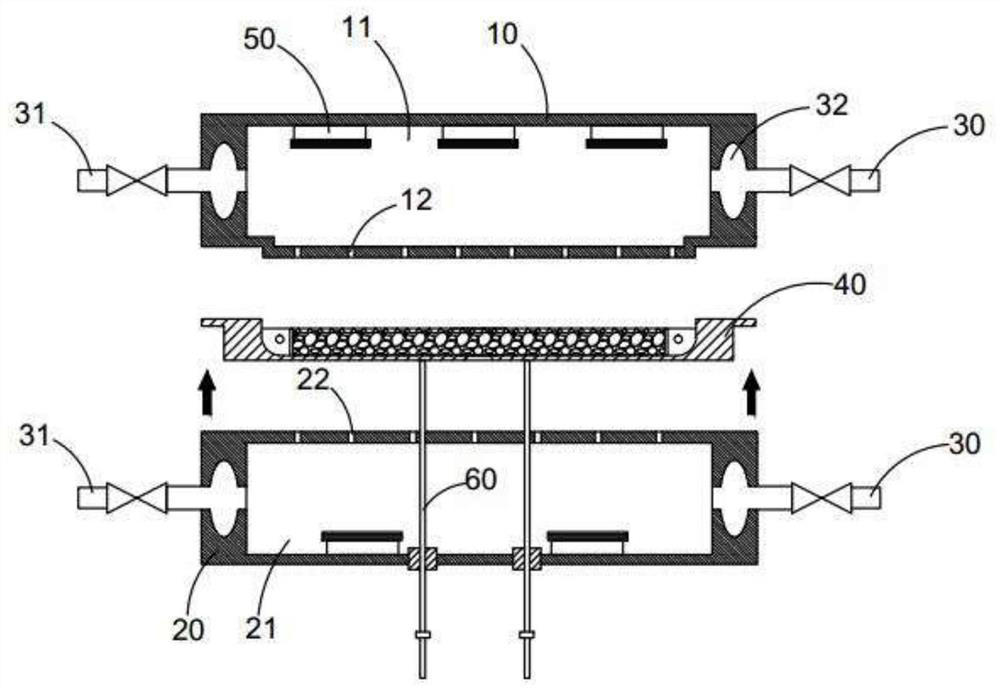

[0039] see Figure 1-6 Shown, a foam molding machine using electromagnetic wave heating, including:

[0040] Molding assembly 40, the surface of molding assembly 40 offers molding grooves for foam molding;

[0041] The solid mold assembly 20 is engaged with the bottom surface of the molding assembly 40, the molding groove of the molding assembly 40 is arranged on the surface opposite to the clamping surface of the solid mold assembly 20, and the solid mold assembly 20 is provided with a solid mold processing chamber 21 , the solid mold processing chamber 21 is equipped with a heat supply component 50 heated by electromagnetic waves;

[0042] The mold shifting assembly 10 is arranged on the molding groove surface of the molding assembly 40, and the bottom of the mold shifting assembly 10 has a protrusion corresponding to the groove shape of the molding groove embedded in the molding groove, and the mold shifting assembly 10 is provided with a mold The processing chamber 11 is...

Embodiment 2

[0054] The foam plastic heating method of the foam plastic molding machine adopting electromagnetic wave heating, the steps are as follows:

[0055] -Assembling the moving mold assembly 10, the molding assembly 40, and the solid mold assembly 20 in sequence to form a foam molding space;

[0056] -Adopt the feeding assembly 80 to feed foamed plastic molding particles into the foamed plastics molding space;

[0057] -Use the thermal energy supply assembly 50 to convert electrical energy into thermal energy through electromagnetic waves to heat the foamed plastic particles to form foamed plastics;

[0058] - through the water inlet pipe body 30 and the water outlet pipe body 31, mold and molded foamed plastics in the water inlet and outlet cooling areas of the mold transfer processing chamber 11 / solid mold processing chamber 21;

[0059] - Release treatment.

[0060] In the present invention, by designing the fixed mold assembly 20 to carry out fixed connection to the molding a...

Embodiment 3

[0062] Foam preparation test:

[0063] Three groups of test groups are set to produce polypropylene foam plastics and perform performance testing. The amount of foamed plastic raw materials and the molding structure of the three groups of test groups are all consistent. Test group 1 adopts the foam plastic molding machine of embodiment 1 and the molding method of embodiment 2 to prepare polypropylene foam Propylene foam plastics; test group 2 adopts the foam plastic molding machine of embodiment 1 and the molding method of embodiment 2 to prepare polypropylene foam plastics, wherein the heat energy supply assembly 50 in the foam plastic molding machine in embodiment 1 is in front of the electromagnetic wave emission port The broken net assembly is not installed; the experimental group 3 adopts the existing foam molding machine for molding processing, and the specific molding method is as follows: 1) Filling the mold: Specifically, put the foamed PP particles into the mold cavit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com