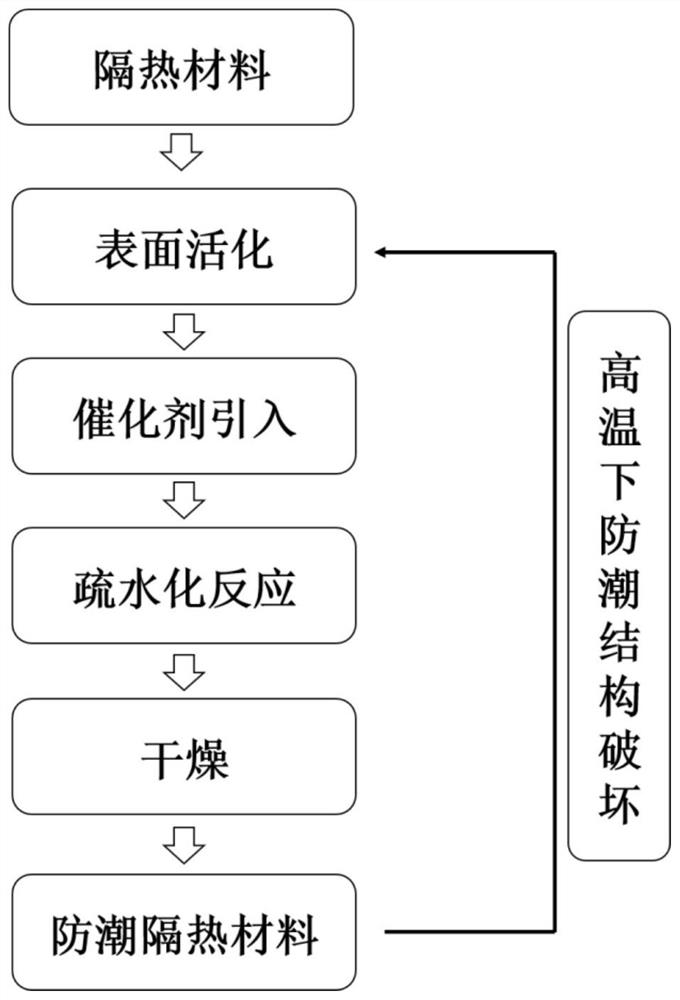

Moisture-proof treatment method and application of heat insulation material

A technology of thermal insulation material and moisture-proof treatment, applied in fiber processing, textiles and papermaking, etc., can solve the problems of inability to online hydrophobicity of thermal protection system, restricting use, etc., achieve stable and controllable weight gain, excellent moisture-proof performance, and reduce technology effect of difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] The size is 500mm×500mm×30mm, the density is 0.25g / cm 3 A piece of commercially available quartz fiber reinforced silica airgel composite sheet without moisture-proof treatment with room temperature thermal conductivity of 0.02W / (m·K) is placed in a ziplock bag, and put into the bag with 20g water container, then seal the bag at room temperature and normal pressure for 4 to 8 hours. Take out the water container and replace it with 2g of ethanol ammonia solution with a mass fraction of 20%. After keeping it for 4 to 8 hours, take out the container and replace it with a container containing 20g of dimethylmethoxysilane, keep the system sealed for 12 After 2 hours, the composite material plate is taken out and placed in a naturally ventilated place until it reaches a constant weight for about 2 to 4 hours. The weight of the material increases by 2%, and the surface is in a superhydrophobic state. According to GB / T 12704 2009 test after random sampling, the moisture absorp...

Embodiment 2

[0065] The size is 500mm×500mm×30mm, the density is 0.2g / cm 3 , commercially available quartz fiber insulation tiles with room temperature thermal conductivity of 0.06W / (m K) are placed in a ziplock bag, and a container containing 10g of water is put into the bag, and the bag is sealed at room temperature and normal pressure to maintain 4 to 8 hours. Take out the water container and replace it with 2g of ethanol ammonia solution with a mass fraction of 20%, keep it for 4 to 8 hours, take out the container, spray 20g of dimethylmethoxysilane on the surface of the sample, and keep the system sealed for 8 hours , Take out the composite sheet and place it in a naturally ventilated place until it reaches a constant weight for about 2 to 4 hours, the weight of the material increases by 3%, and the surface is in a superhydrophobic state. After random sampling, according to GB / T 127042009, the moisture absorption rate is 0.7%, and the room temperature thermal conductivity of the mate...

Embodiment 3

[0067] The size is 500mm×500mm×30mm, the density is 0.1g / cm 3 A commercially available quartz fiber felt with a thermal conductivity of 0.03W / (m K) at room temperature is placed in a ziplock bag, a container containing 5g of water is put into the bag, and the bag is sealed at room temperature and normal pressure for 3 to 5 hours. Take out the water container and replace it with 1g of methanol ammonia solution with a mass fraction of 20%, keep it for 3 to 5 hours, take out the container, spray 10g of methylmethoxysilane on the surface of the sample, and keep the system sealed for 6 hours to After 8 hours, take out the composite sheet and place it in a naturally ventilated place until it reaches a constant weight in about 2 to 4 hours. The weight of the material increases by about 3%, and the surface is in a superhydrophobic state. After random sampling, according to GB / T 127042009, test the moisture absorption rate of 0.6%, and the room temperature thermal conductivity of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com