An electroplating time adjustment device for automatic electroplating equipment

A technology for electroplating equipment and time adjustment, which is applied to electrolytic components, electrolytic processes, cells, etc., can solve the problems of inflexible use, etc., and achieve the effects of easy promotion, simplified structure and wide application range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

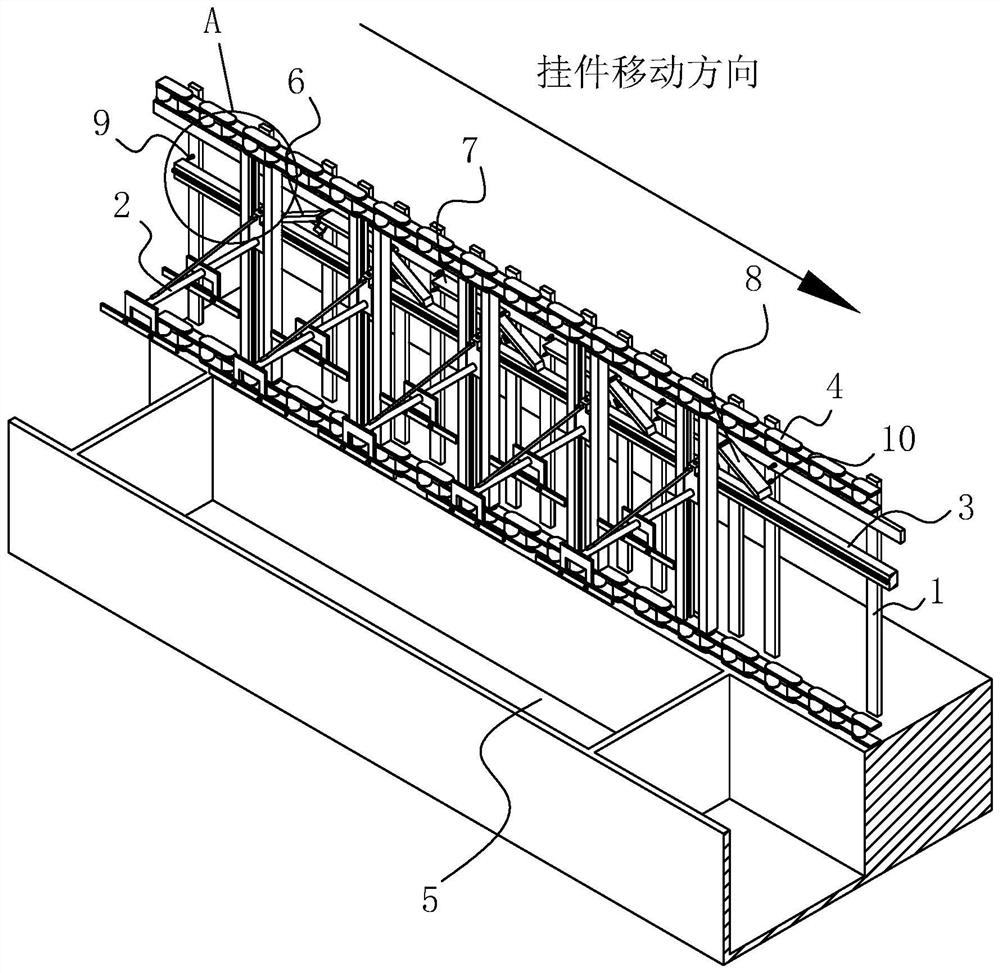

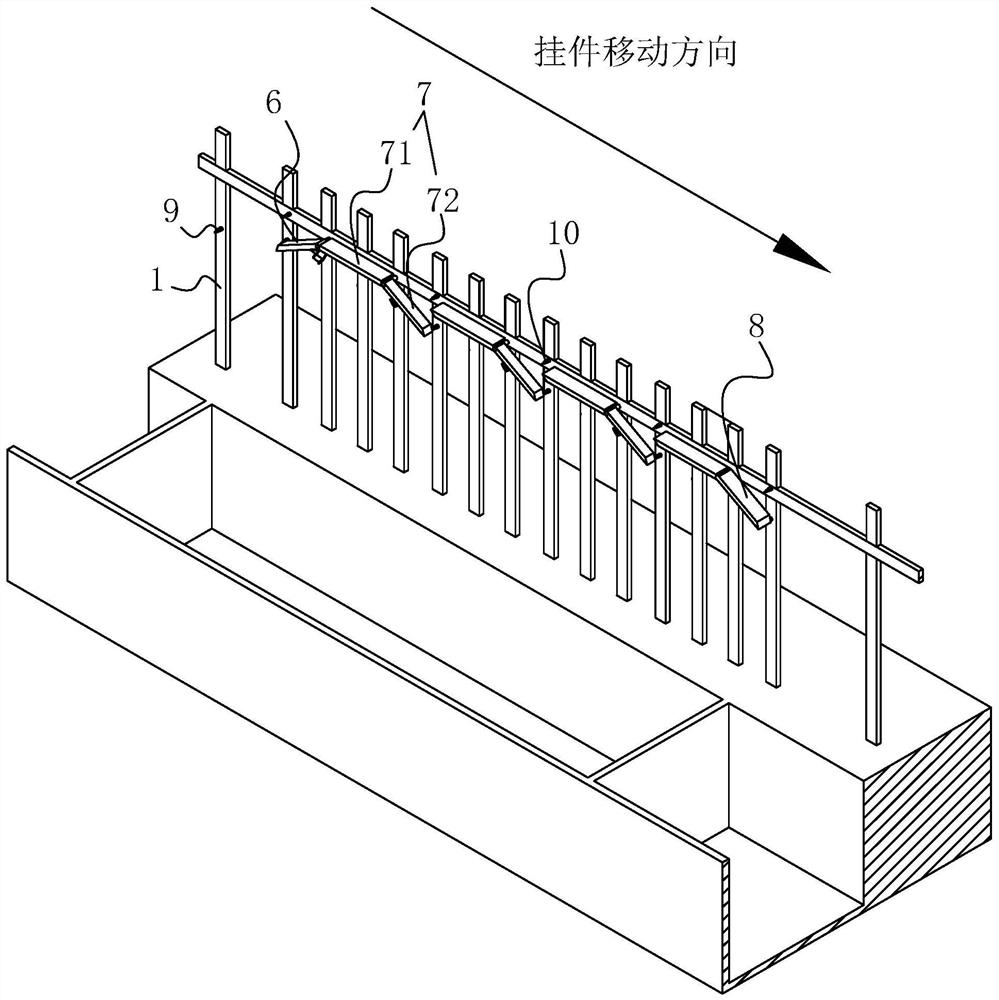

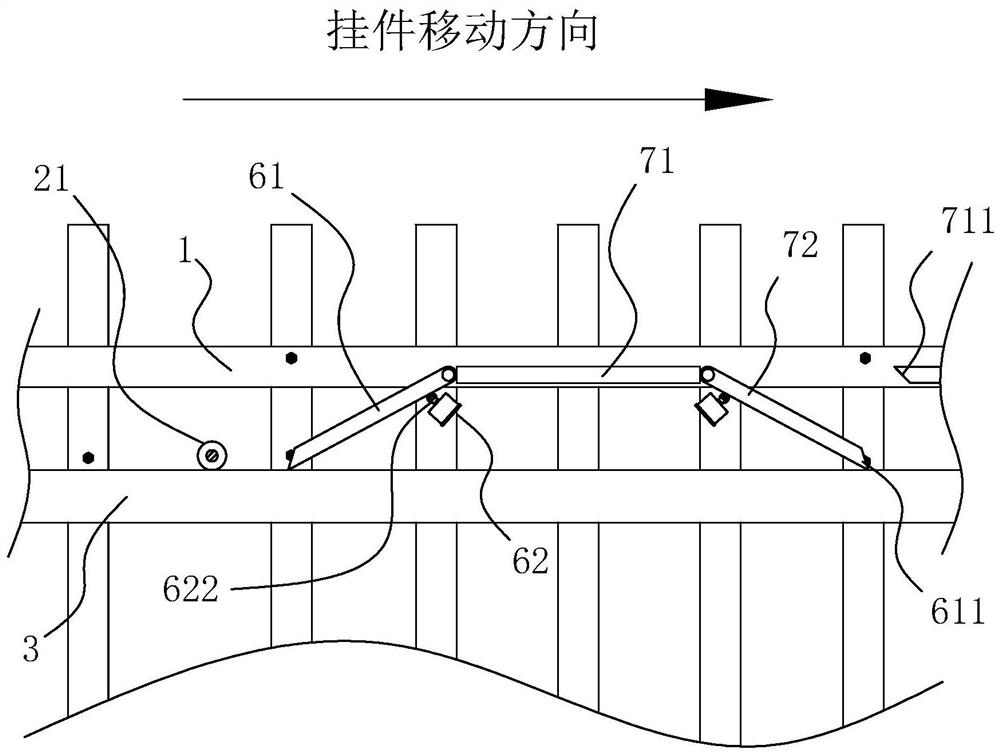

[0047] Example 1: Combining figure 1 and figure 2 As shown, it is an electroplating time adjustment device for automatic electroplating equipment disclosed by the present invention. The electroplating time adjustment device is located above one of the treatment tanks 5, and the electroplating time adjustment device includes a frame set on the automatic electroplating equipment 1 and above the constant track 7 so that part of the hanging parts 2 will not move down with the circular track 3. The constant track 7 is set on the frame 1 of the automatic electroplating equipment and is located on the side where the constant track 7 is opposite to the moving direction of the hanging parts 2. One end is used to transfer the pendant 2 on the circular track 3 to the upward track assembly 6 on the constant track 7 and is arranged on the frame 1 of the automatic electroplating equipment and is positioned on the end of the constant track 7 away from the upward track assembly 6 to It is u...

Embodiment 2

[0058] Embodiment two: if Figure 7 As shown, the difference from Embodiment 1 is that several groups of guide assemblies 12 are arranged on the frame 1 and located at the end of each sub-rail 71 close to the upper rail 61, and the upper rail 61 and each connecting rail 72 are arranged horizontally. And it is vertically slidably connected to the guide assembly 12 , and the driving device 62 is configured as a motor screw transmission mechanism 623 for driving the upward rail 61 or the connecting rail 72 to go up and down.

[0059] Specifically, each group of guide assemblies 12 includes two guide rails 121 arranged vertically and parallel to each other. When the up track 61 or the connecting track 72 lifts up and down, the two track slide rails can play the guiding effect of stably supporting the two ends of the upper and lower tracks or the connecting track 72 .

[0060] Specifically, the motor screw transmission mechanism 623 includes a common motor 624 whose body is fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com