Energy consumption type connecting beam

An energy-consuming, connecting-beam technology, which is applied in building types, building components, and earthquake resistance, can solve problems such as the threat of aftershocks to shear walls, damage to connecting beams, and difficult repairs, etc., to achieve easy disassembly and replacement, and improve energy consumption capacity , The effect of convenient construction and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

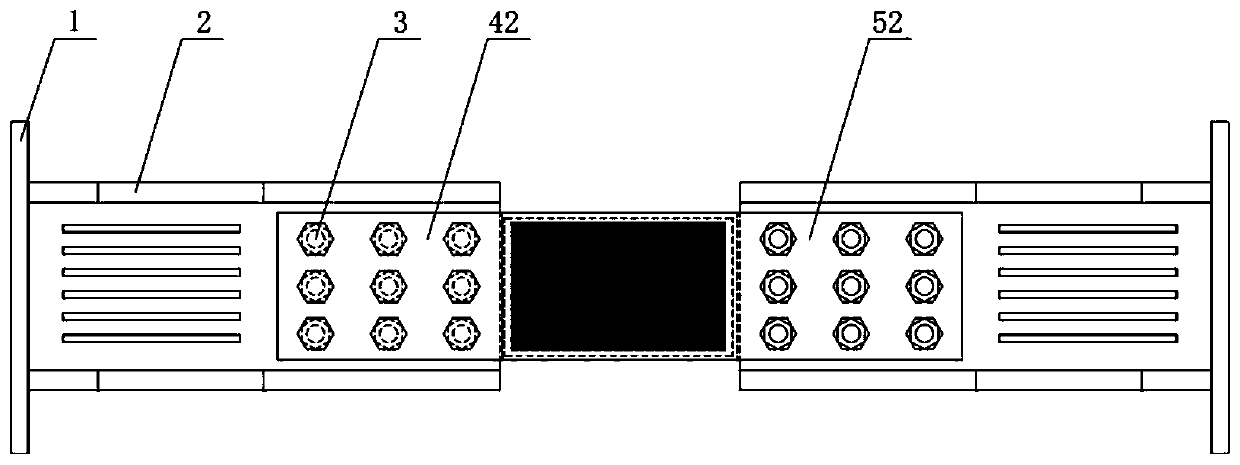

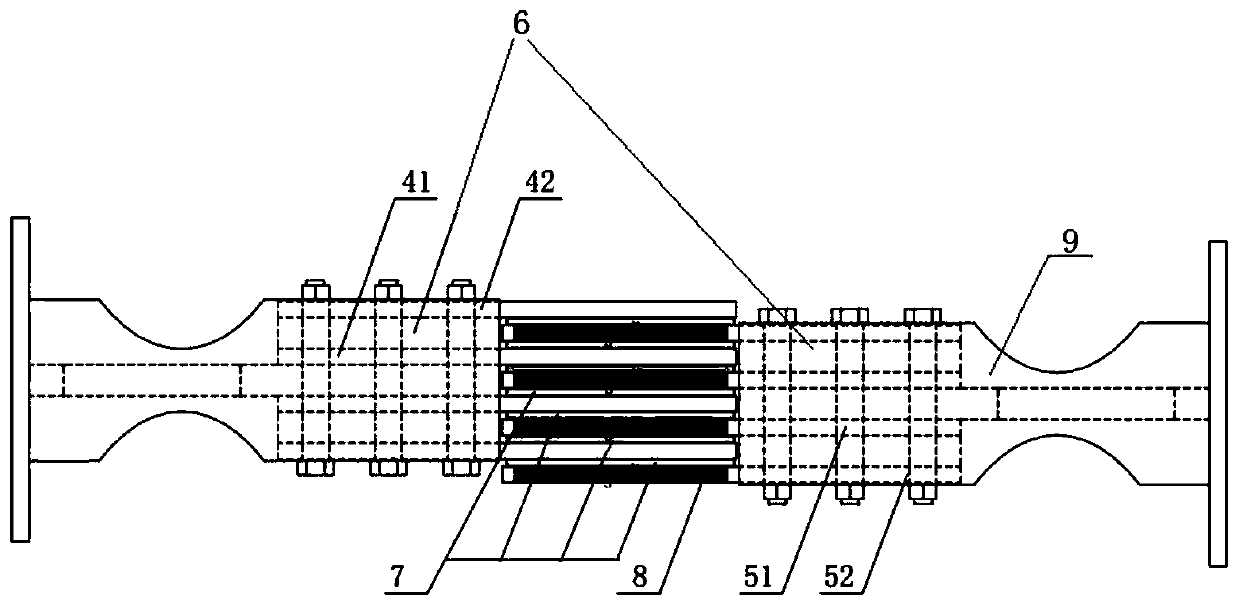

[0032] This embodiment provides a full-stage high-efficiency energy-consuming replaceable coupling beam combined with viscoelasticity and eddy current. The functional device includes a mild steel assembly (metal damper) and a damper. The mild steel assembly includes a first mild steel part 2 and a second mild steel part 9. One end of the first mild steel part 2 is connected to an end plate 1, and the second soft steel part 2 is connected to an end plate 1. One end of the steel piece 9 is connected to the other end plate 1, and a damper is connected between the first soft steel piece 2 and the second soft steel piece 9, and the damper is a composite body composed of an eddy current damper and a viscoelastic damper. Combining the shear energy dissipation advantages of the three dampers, a replaceable connecting beam with high shear energy dissipation strength is formed comprehensively; the eddy current damper and the viscoelastic damper form a complex in a cross-fitting manner, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com