Self-sensing eddy current type replaceable energy-consuming coupling beam

An eddy current and self-sensing technology, applied in the direction of joists, girders, trusses, etc., can solve the problems of shear damage, lead rubber damper wear, poor accuracy, etc., to achieve real-time monitoring, reduce earthquake damage, The effect of improving comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

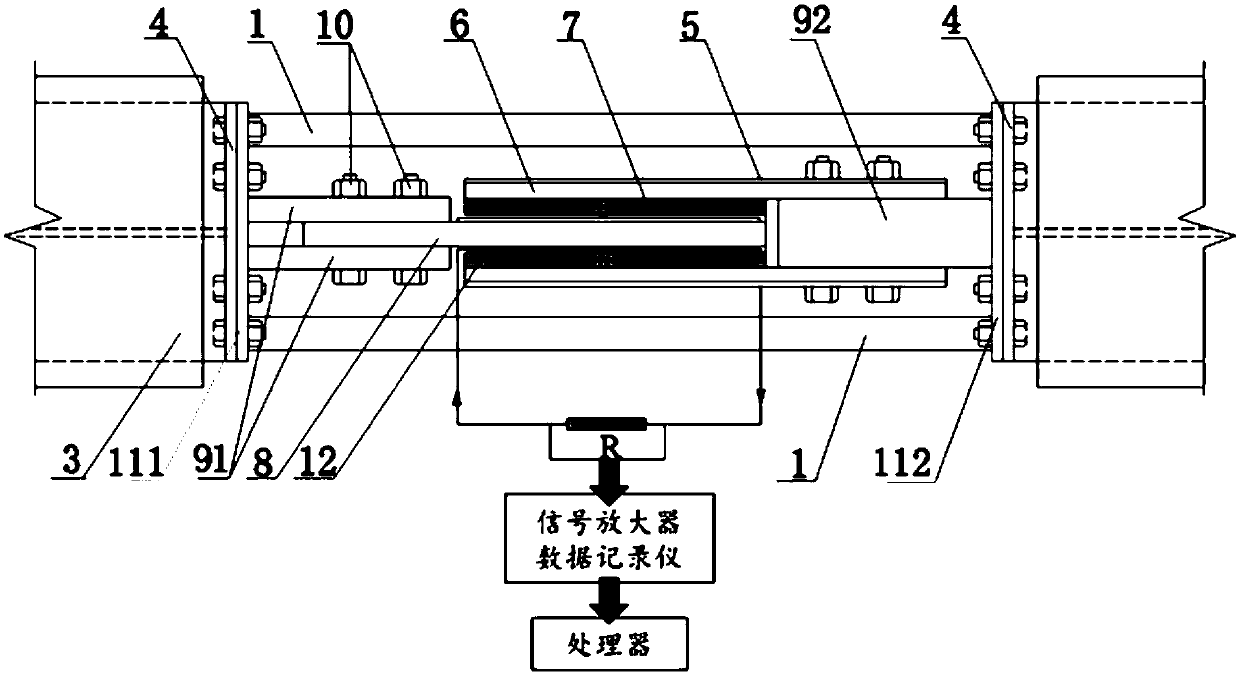

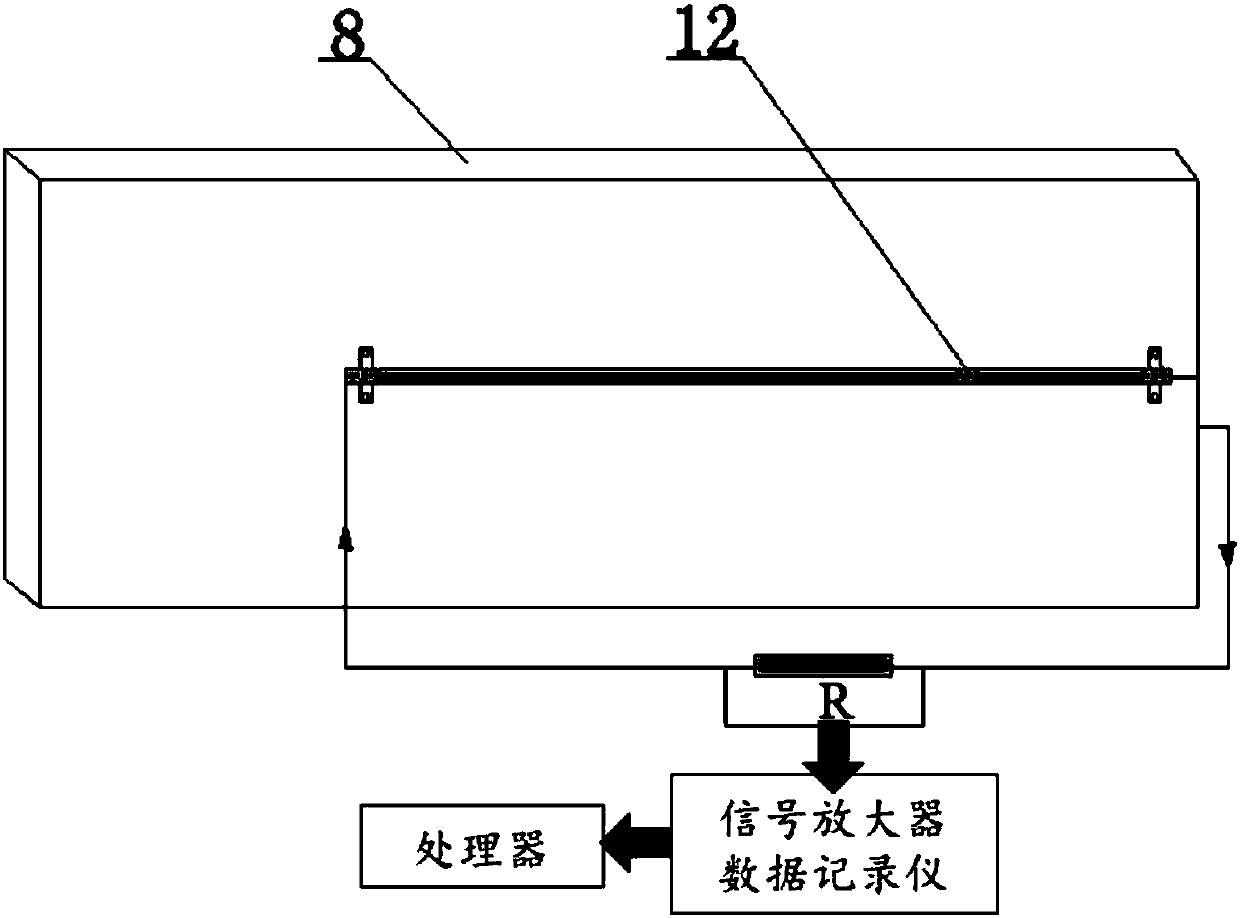

[0027] The purpose of the patent of the present invention is to provide a self-sensing eddy current type replaceable energy-dissipating connecting beam. The connecting beam realizes the safety and comfort of protecting the main body at all stages through the combination of the eddy current damper and the metal energy-dissipating damper, and at the same time achieves The goal of the self-monitoring of the coupling beam during the earthquake is to overcome the shortcomings of the existing replaceable energy-dissipating coupling beams with poor deformation capacity, stability and durability, and to be easy to repair and replace after a major earthquake.

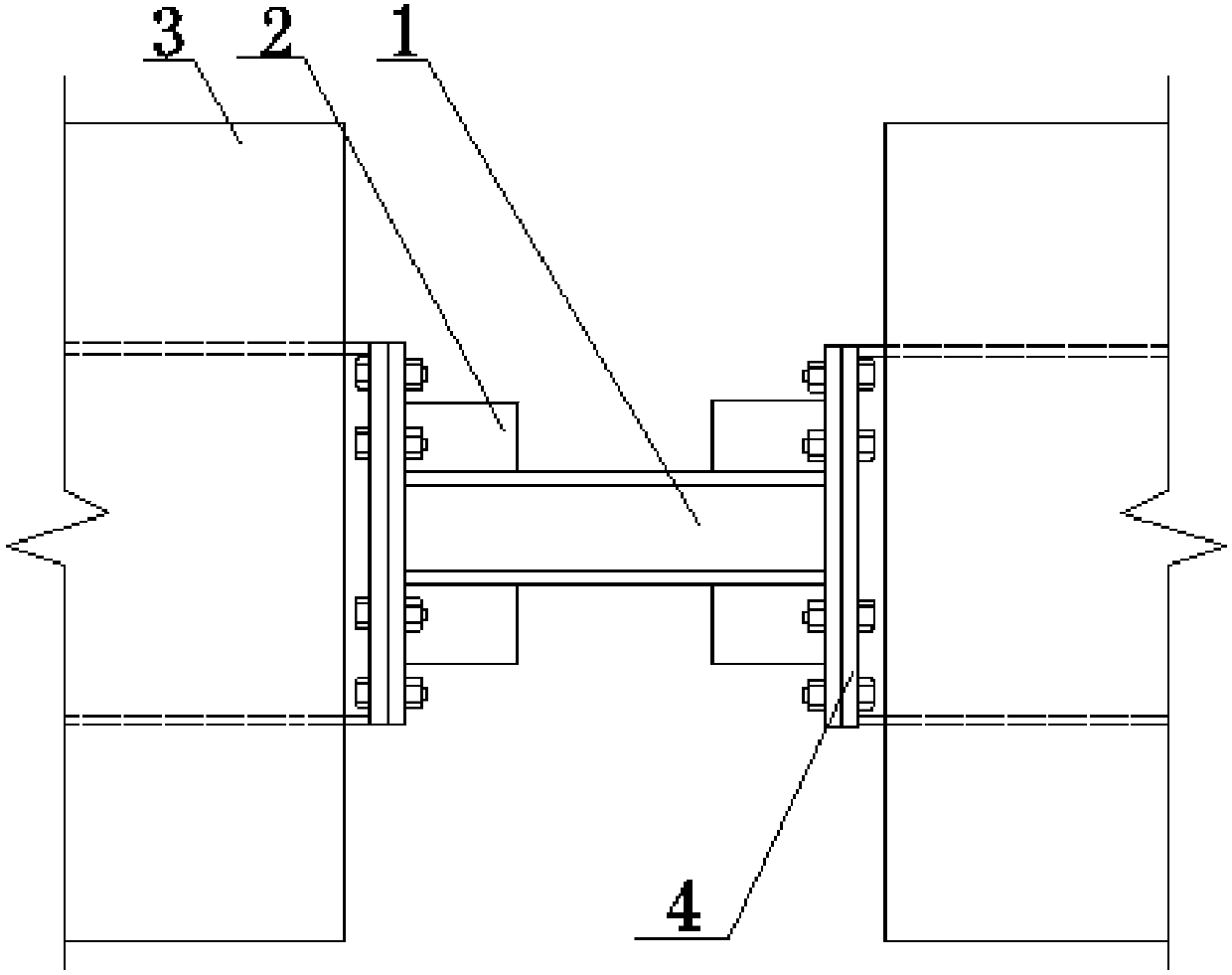

[0028] Such as Figure 1-3 As shown, the present invention provides a self-sensing eddy current replaceable energy-dissipating coupling beam, which consists of a non-energy-dissipating section 3 and a replaceable section. The replaceable section is composed of an eddy current damper 2 and two shaped steel plates 1 connected in p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com