Intelligent self-monitoring and self-repairing memory alloy composite beam

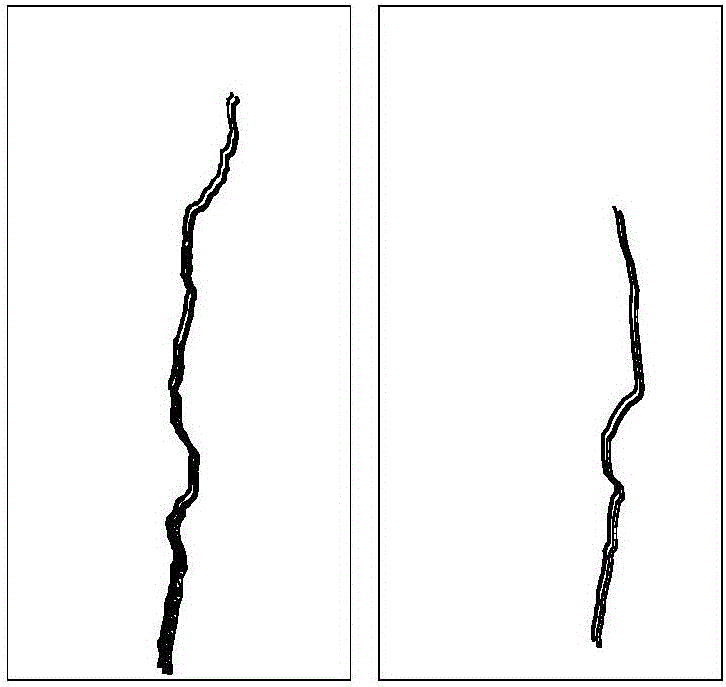

A memory alloy and self-monitoring technology, applied in bridges, bridge parts, bridge construction, etc., can solve problems such as composite beam fatigue damage, fatigue crack damage, crack defects, etc., and achieve the effect of self-monitoring and self-warning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

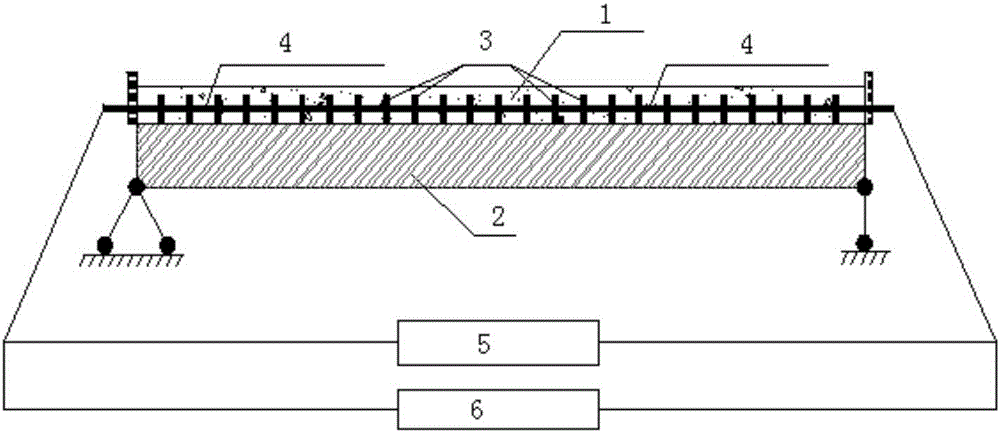

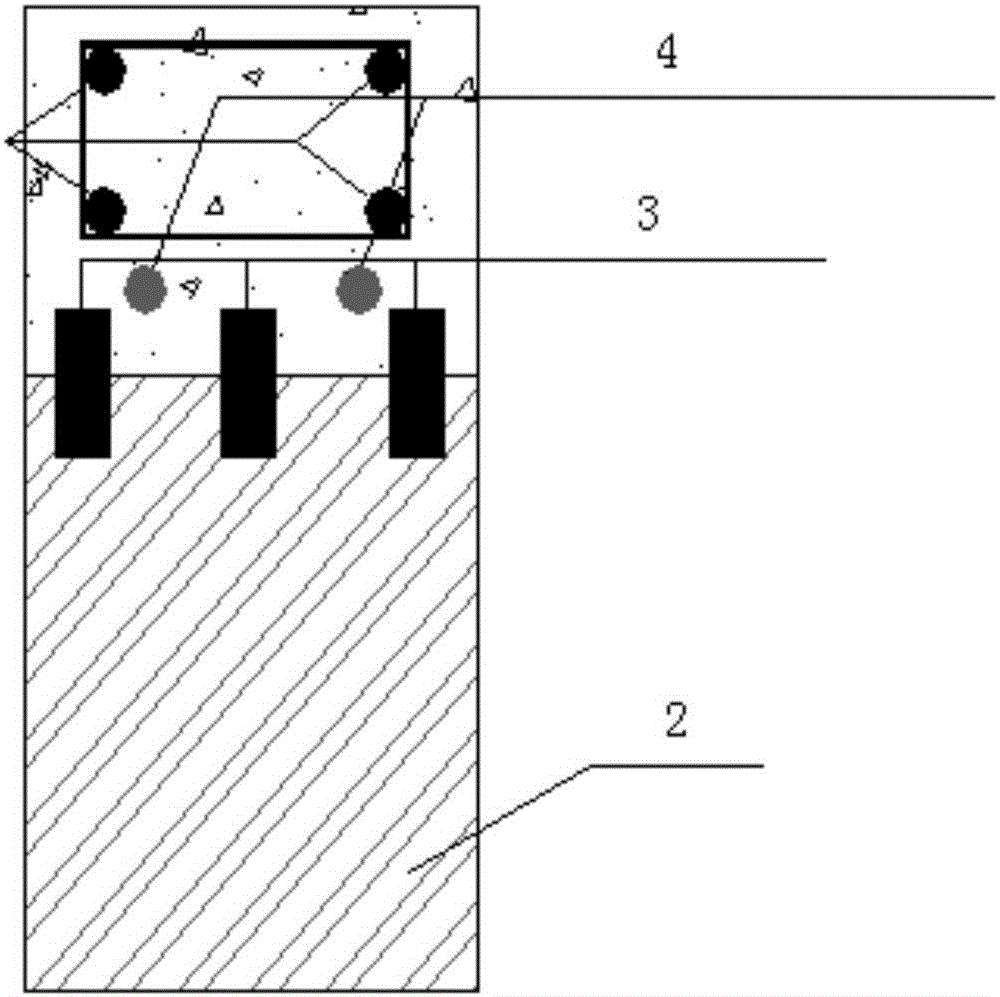

[0022] refer to figure 1 and figure 2 , intelligent self-monitoring and self-healing memory alloy composite beam, including upper concrete slab 1 and lower I-beam 2, also including memory alloy shear nails 3 as sensing elements and carbon fiber-reinforced concrete embedded in the upper concrete slab along the beam length direction The memory alloy composite 4 and the memory alloy shear nails 3 are used to connect the upper concrete slab 1 and the lower I-beam 2 .

[0023] Further, the carbon fiber-memory alloy composite 4 is a driving element, which is used to close the crack of the component under current excitation.

[0024] Further, the memory alloy adopts a single-pass memory effect alloy, and the single-pass memory effect alloy deforms at a lower temperature, and can effectively restore the shape before the deformation after heating.

[0025] Further, it also includes an alloy resistance measurement circuit 5 and an alloy excitation drive circuit 6, and the alloy resis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com