A Combined Wind and Earthquake Resistant Beam Energy Dissipator

An anti-seismic coupling and combined technology, which is applied in the direction of building types, buildings, protected buildings/shelters, etc., can solve the problem that coupling beams cannot meet small earthquakes at the same time, are not suitable for large deformation seismic structures, and have limited shear deformation capacity, etc. problems, to achieve the effect of simple structure, easy processing, and good energy dissipation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

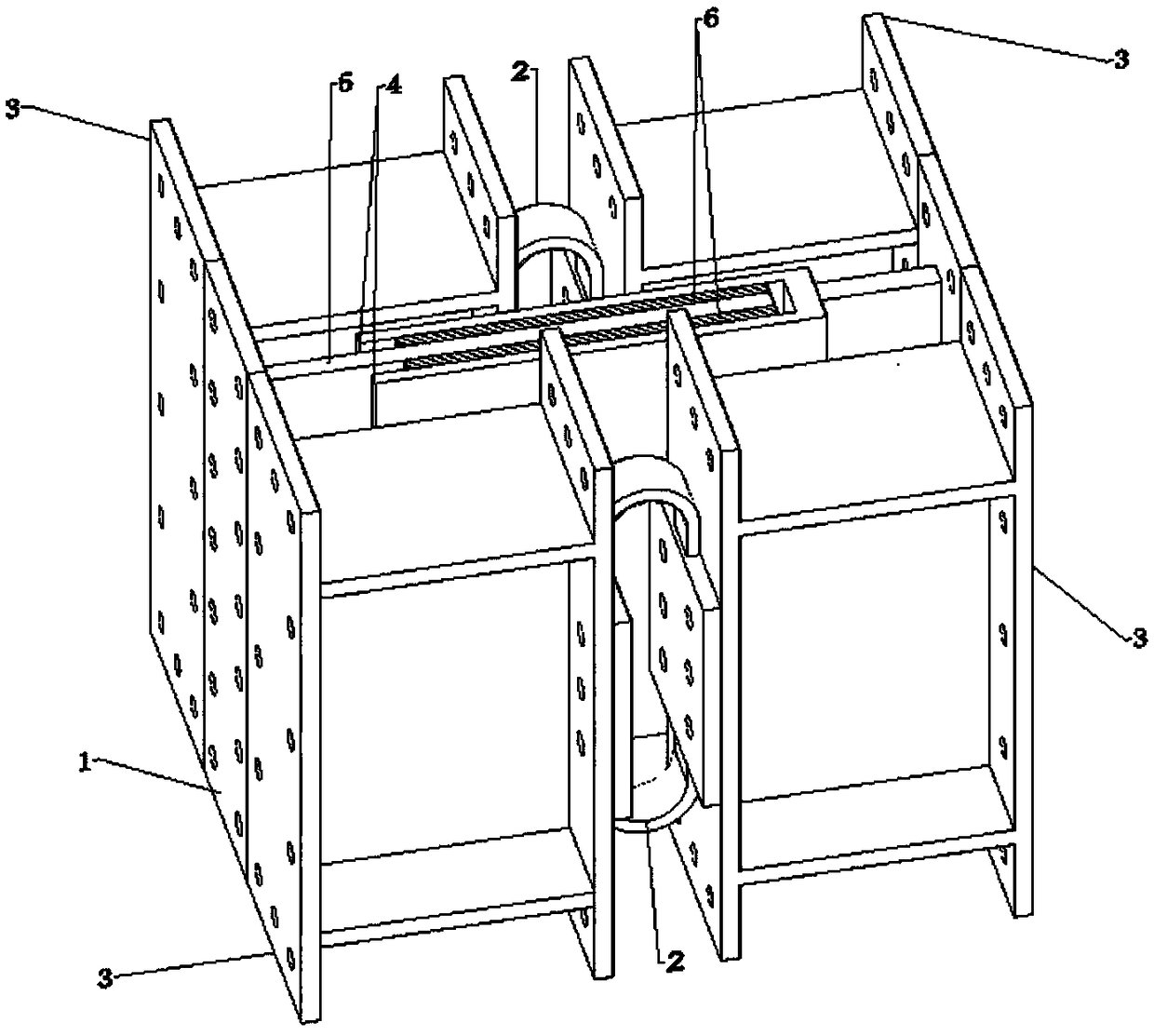

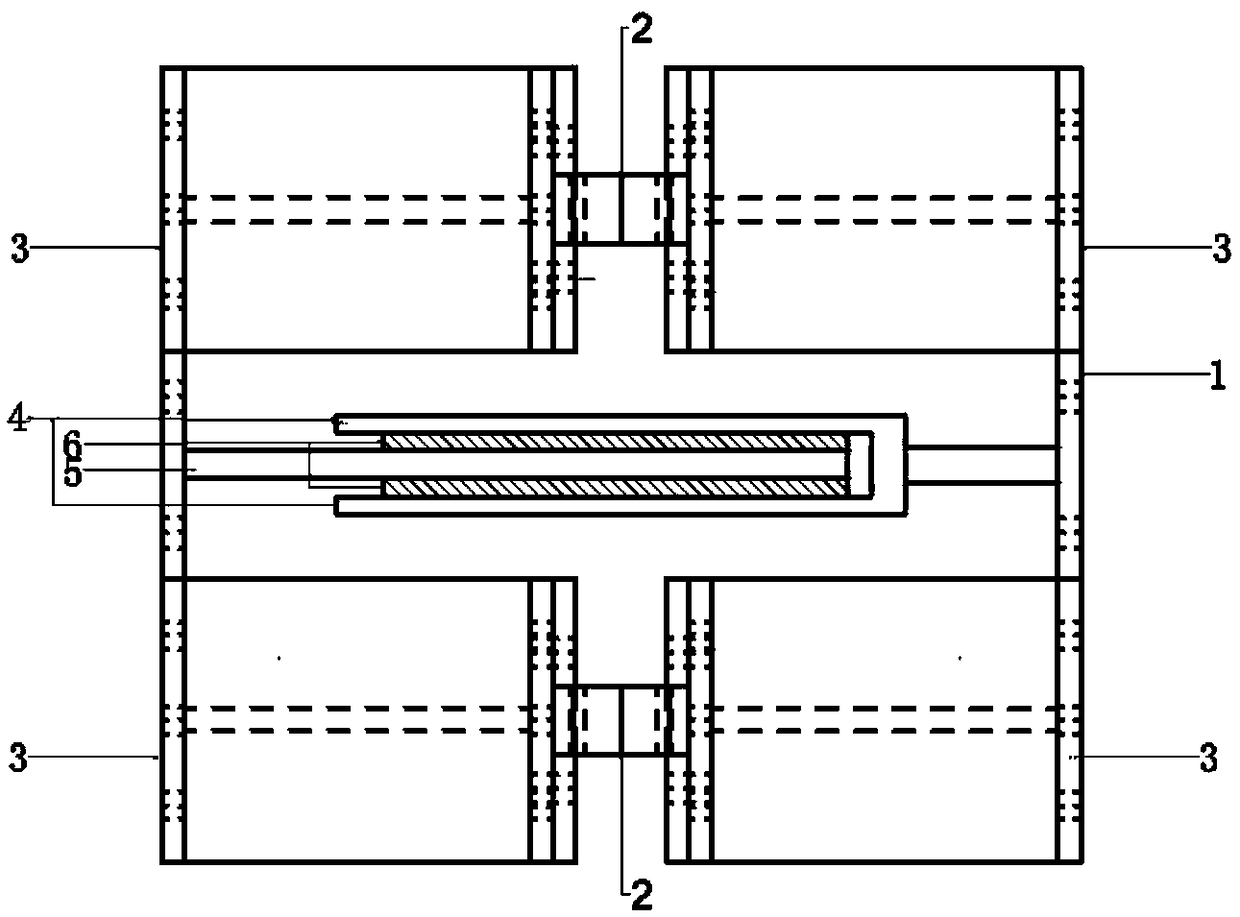

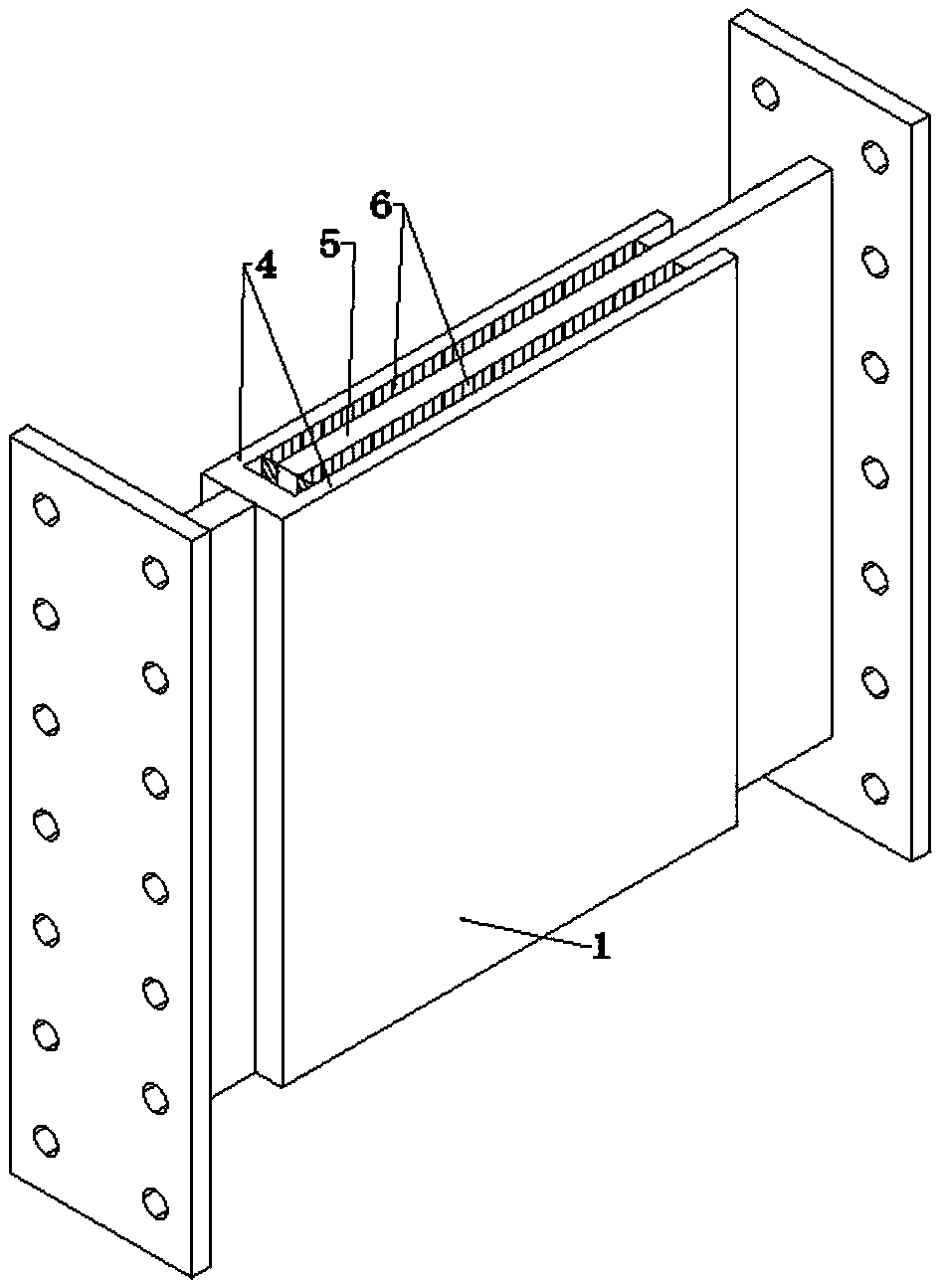

[0031] The present invention provides a combined wind and earthquake resistant coupling beam energy dissipator, comprising two O-shaped metal dampers 2, one viscoelastic damper 1 and four pad beams 3, two O-shaped metal dampers 2 and viscoelastic The dampers 1 are set in parallel and the viscoelastic damper 1 is set between two O-shaped metal dampers 2. The two ends of 2 are respectively connected to the wall through the pad beam 3, and the two ends of the viscoelastic damper 1 are respectively connected to the embedded parts of the wall.

[0032] The section of the pad beam 3 is I-shaped, H-shaped, rectangular or groove-shaped, and the end plate connected with the O-shaped metal damper 2 on the pad beam 3 is provided with several bolt holes.

[0033] The O-shaped metal damper 2 includes two U-shaped steel plates and two rigid end plates. The two U-shaped steel plates are arranged symmetrically up and down and fixedly connected to the rigid end plates on both sides respectivel...

Embodiment 2

[0041] This embodiment has made further improvements on the basis of Embodiment 1, which includes all the content of Embodiment 1, that is, the combined wind-resistant and anti-seismic coupling beam energy dissipator in this embodiment includes the combined wind-resistant All the structural features of the seismic coupling beam energy dissipator, the specific improvements are as follows:

[0042] The combined wind and earthquake resistant coupling beam energy dissipator is also provided with two end plates, and the two end plates are fixedly arranged at both ends of the viscoelastic damper 1 respectively, and the viscoelastic damper 1 is connected to the wall through the end plates.

[0043] The invention can be used in high-rise joint shear wall structures, not only can work and consume energy under small earthquakes or wind vibrations, but also can work and consume energy under moderate earthquakes and large earthquakes, so as to protect the safety of the shear wall limbs and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com