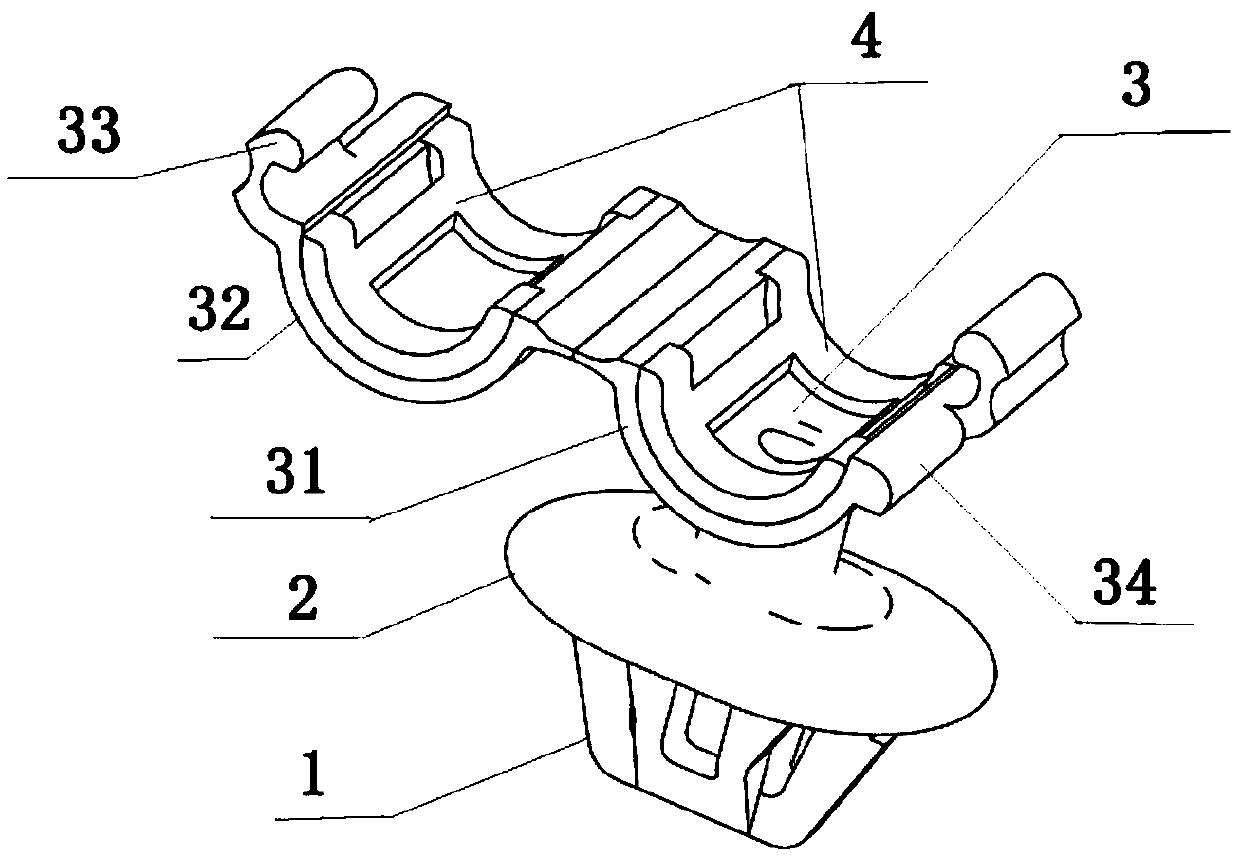

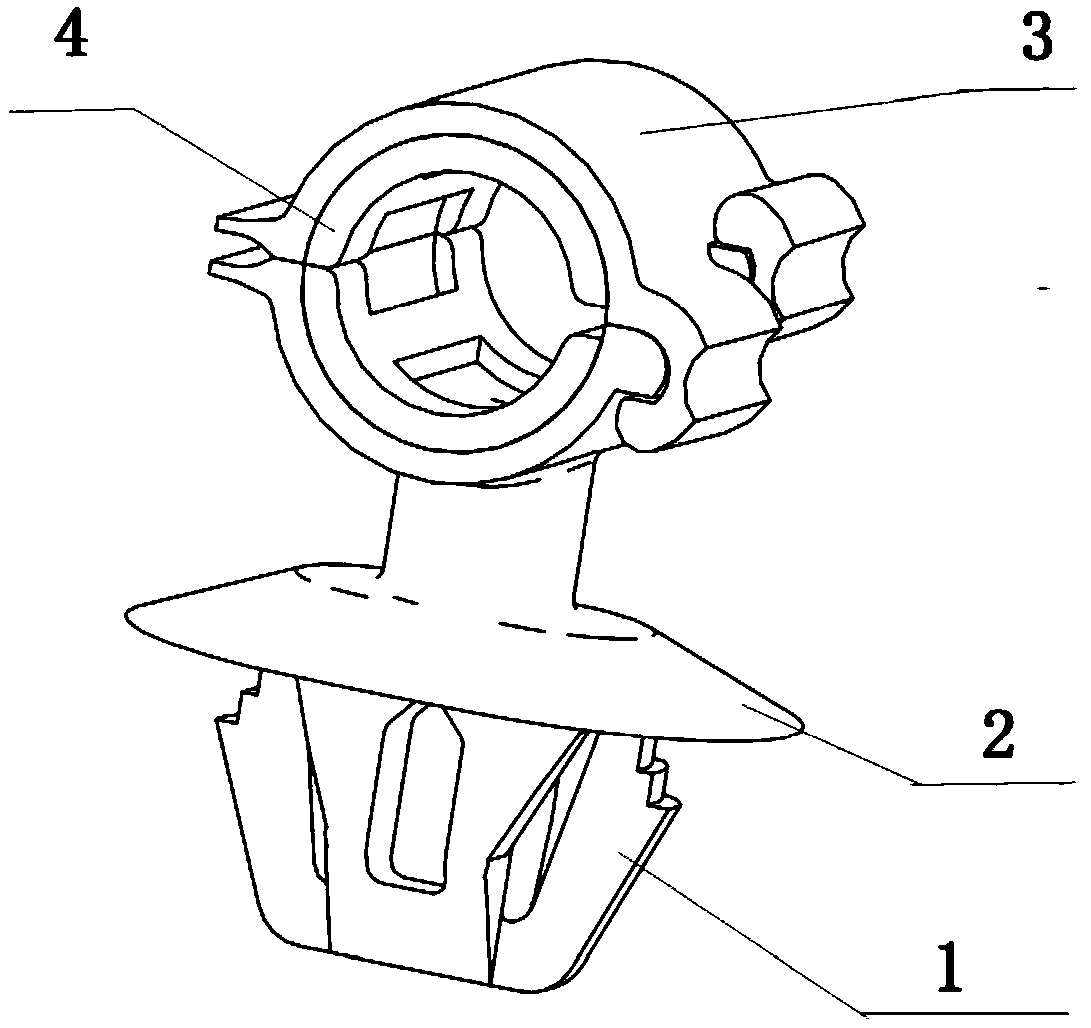

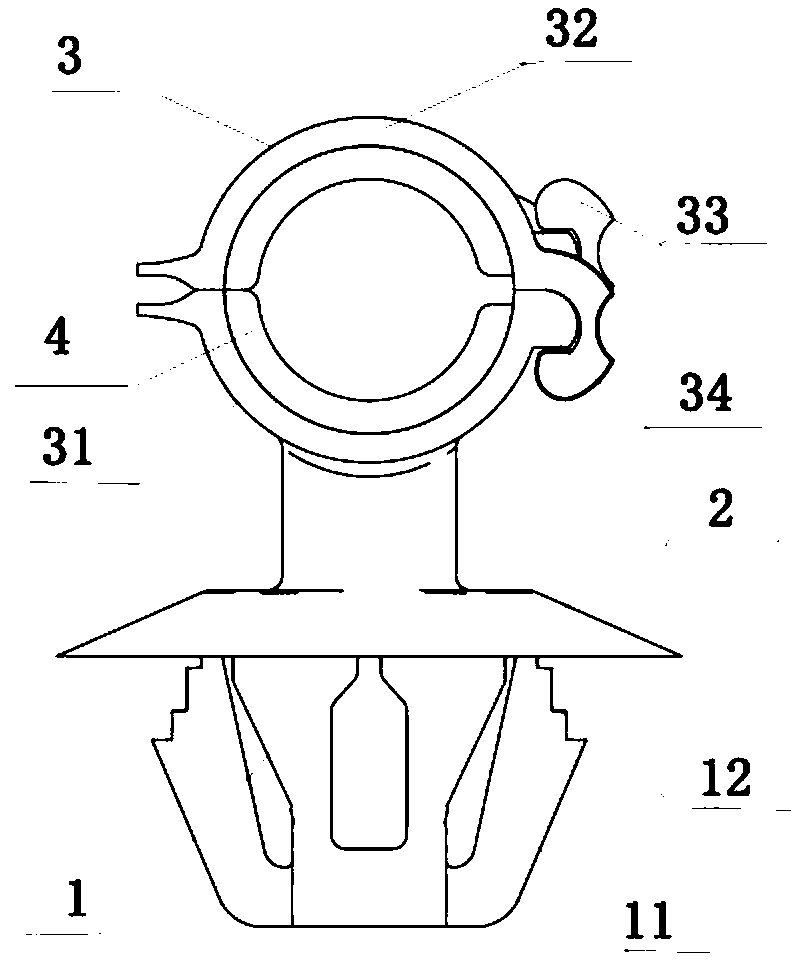

Fixing pipe clamp

A technology for fixing pipes and pipe clamps, which is applied in the direction of pipe supports, pipes/pipe joints/pipe fittings, mechanical equipment, etc. It can solve the problems of decoupling of the buckle structure of fixed pipe clamps, and achieve firm fixation, prevent decoupling, and prevent relative sliding Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 3

[0033] Embodiment 3 of the fixed pipe clamp of the present invention differs from Embodiment 1 in that the enclosing part of the pipe clamp body adopts the enclosure of the "C" shape overall structure of the pipe clamp body in the Chinese utility model patent with the authorized announcement number CN206093207U The closing part is provided with fastening structures at both ends of the enclosing part.

[0034] Embodiment 4 of the fixed pipe clamp of the present invention differs from Embodiment 1 in that there is a gap between the opposite end faces of the hooks on the first enclosing part and the second enclosing part in the axial direction of the perforation of the clamp. When the axial lateral movement occurs with the wire harness, the two hooks are close to each other. After the gap is eliminated, the two hooks still block each other. The existence of the gap between the two hooks reduces the processing accuracy and facilitates processing.

[0035] Embodiment 5 of the fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com