Falling film evaporator and control method

A falling-film evaporator and control method technology, which is applied to evaporators/condensers, refrigerators, refrigeration components, etc., can solve the problem of uneven distribution of refrigerants, and can solve the problem of uneven distribution, improve heat exchange performance, and evenly distribute Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

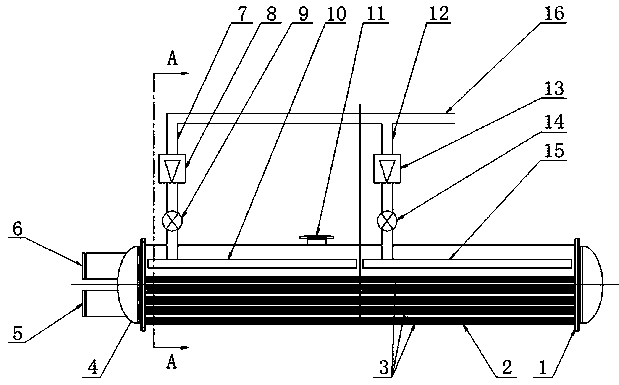

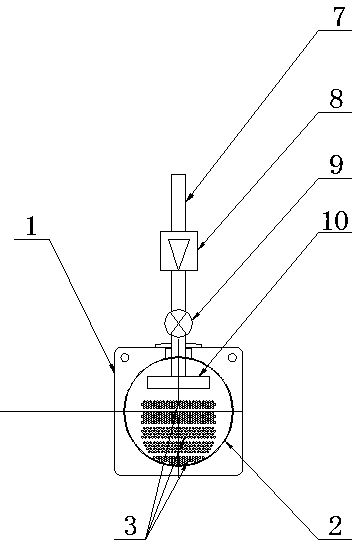

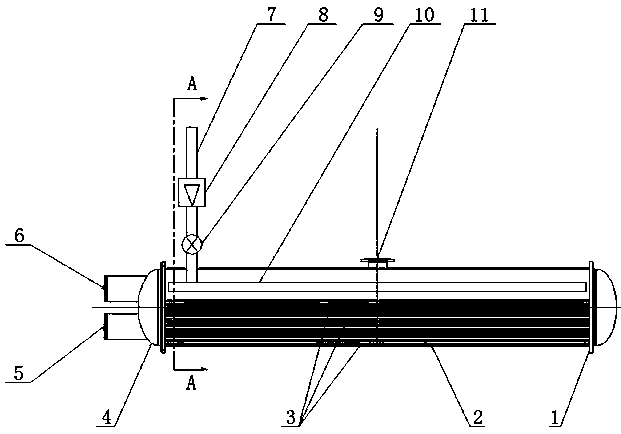

[0035] The falling film evaporator of this embodiment mainly includes a cylinder body 2, and a plurality of heat exchange tubes 3 are arranged inside the cylinder body 2; a plurality of distributors are arranged above the interior of the cylinder body 2 and above the heat exchange tubes 3, see Figure 1 to Figure 4 As shown; multiple distributors are connected in parallel, the liquid inlet pipe of each distributor is connected with the total liquid inlet pipe 16 respectively, and a flowmeter and an electronic expansion valve are connected in series on the liquid inlet pipe of each distributor; each flowmeter is respectively The refrigerant flow signal corresponding to the liquid inlet pipe is collected and sent to the control board, and the control board controls the opening of each electronic expansion valve according to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com