Engine hood dynamic fatigue analysis method

An engine cover and analysis method technology, applied in computer-aided design, geometric CAD, design optimization/simulation, etc., can solve the problems of prolonging the engine cover optimization design cycle, heavy workload, and long time consumption, and shorten the development and design time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing.

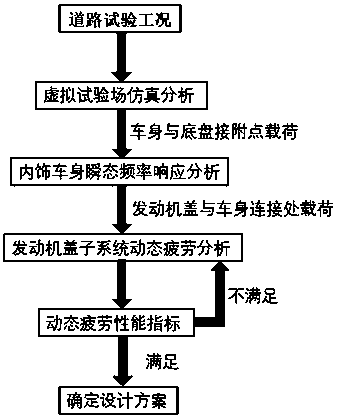

[0024] Such as figure 1 As shown, a dynamic fatigue analysis method of engine cover includes the following steps:

[0025] Step A, load decomposition:

[0026] In order to verify the durability and reliability of the vehicle, it is necessary to conduct different road tests according to different models, that is, to run the vehicle on some roads, such as pebble roads and Belgian roads, for a certain period of time at a certain speed and with a counterweight. In order to speed up the load extraction, these working conditions can be simulated and analyzed on a virtual test site, and the loads of the corresponding road body and chassis attachment points can be obtained respectively.

[0027] Step B. Finite element transient frequency response analysis of the interior body model:

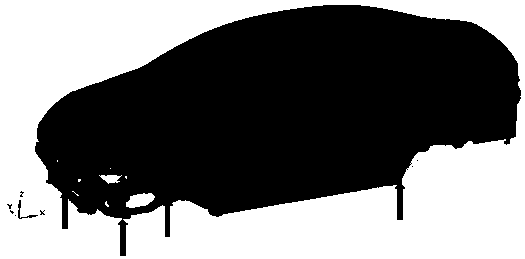

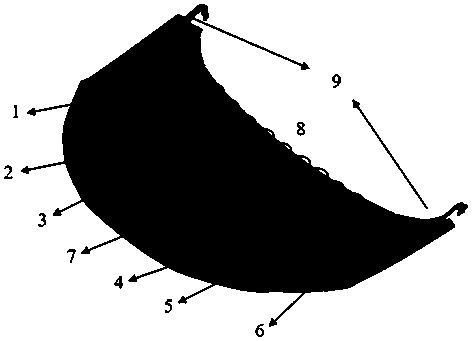

[0028] Prepare the interior body finite element mesh model, such as figure 2 As shown, accord...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com