Display panel and production method thereof

A display panel and display area technology, applied to static indicators, identification devices, instruments, etc., can solve the problems of lack of price advantage, time-consuming design and mask production, and waste of time, so as to shorten the development and design time , The effect of saving development and production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

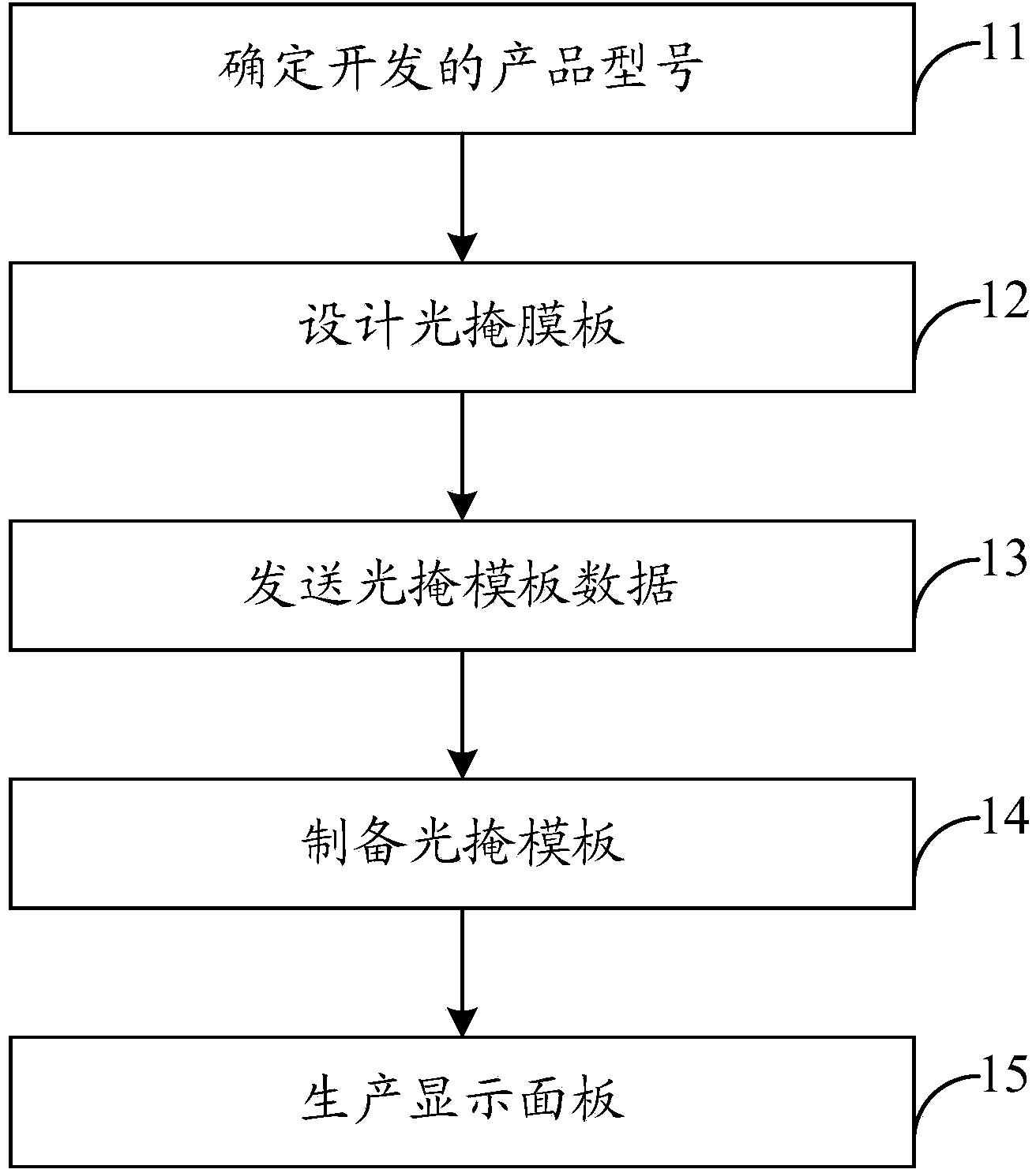

[0048] An embodiment of the present invention provides a method for preparing a display panel, and the method is applied to the display panel provided by the above-mentioned embodiments of the present invention, as shown in the attached Figure 5 As shown, the method may specifically include:

[0049] Step 51, based on the size of the required display panel, determine the range of the display area that needs to be cut in the cutting area of the original display panel;

[0050] Step 52, cut off the area of the display panel that needs to be cut.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com