Shell paint spraying device for electronic product processing

A technology for electronic products and shells, applied in the field of shell painting devices for electronic product processing, can solve problems such as low paint spraying effect and spraying efficiency, and achieve the effects of improving paint spraying quality, stirring thoroughly and improving spraying efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

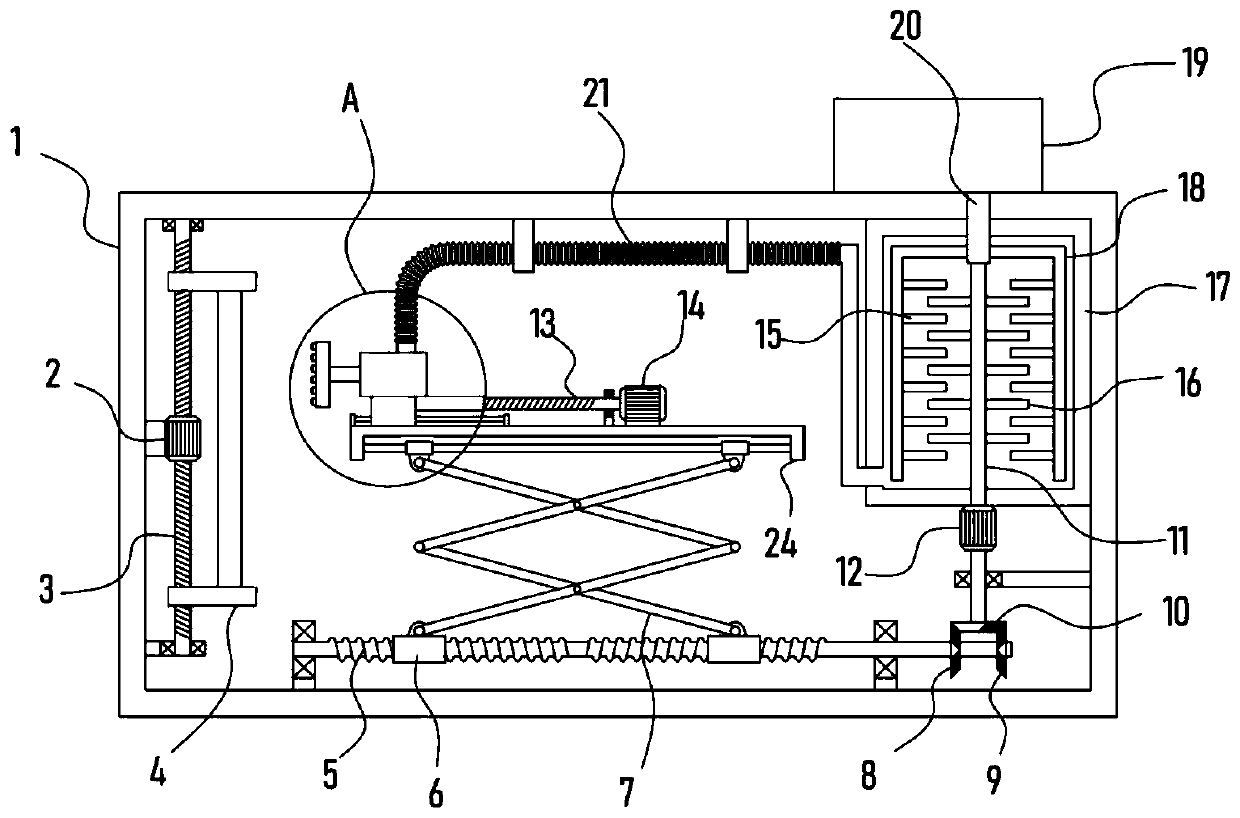

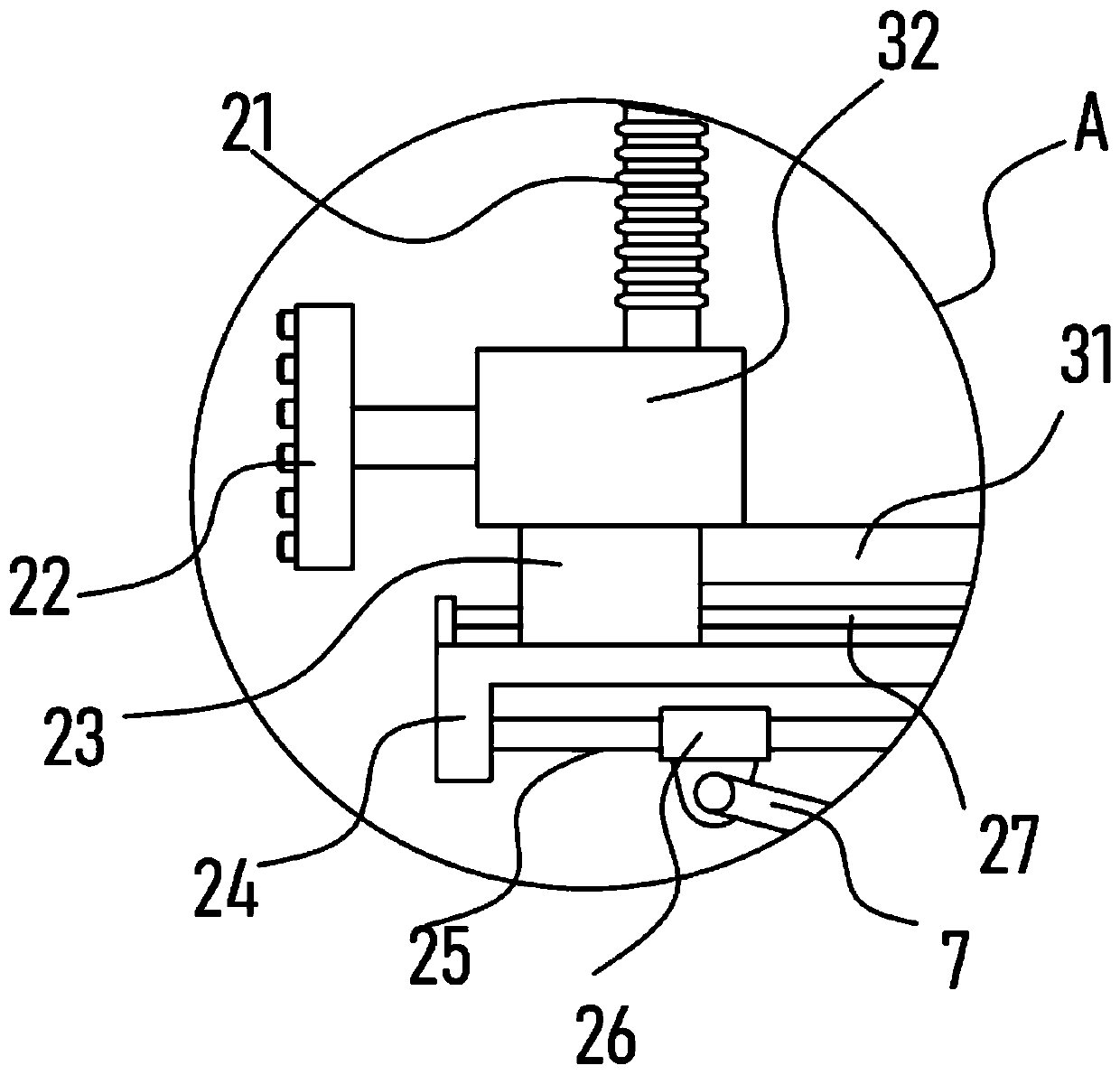

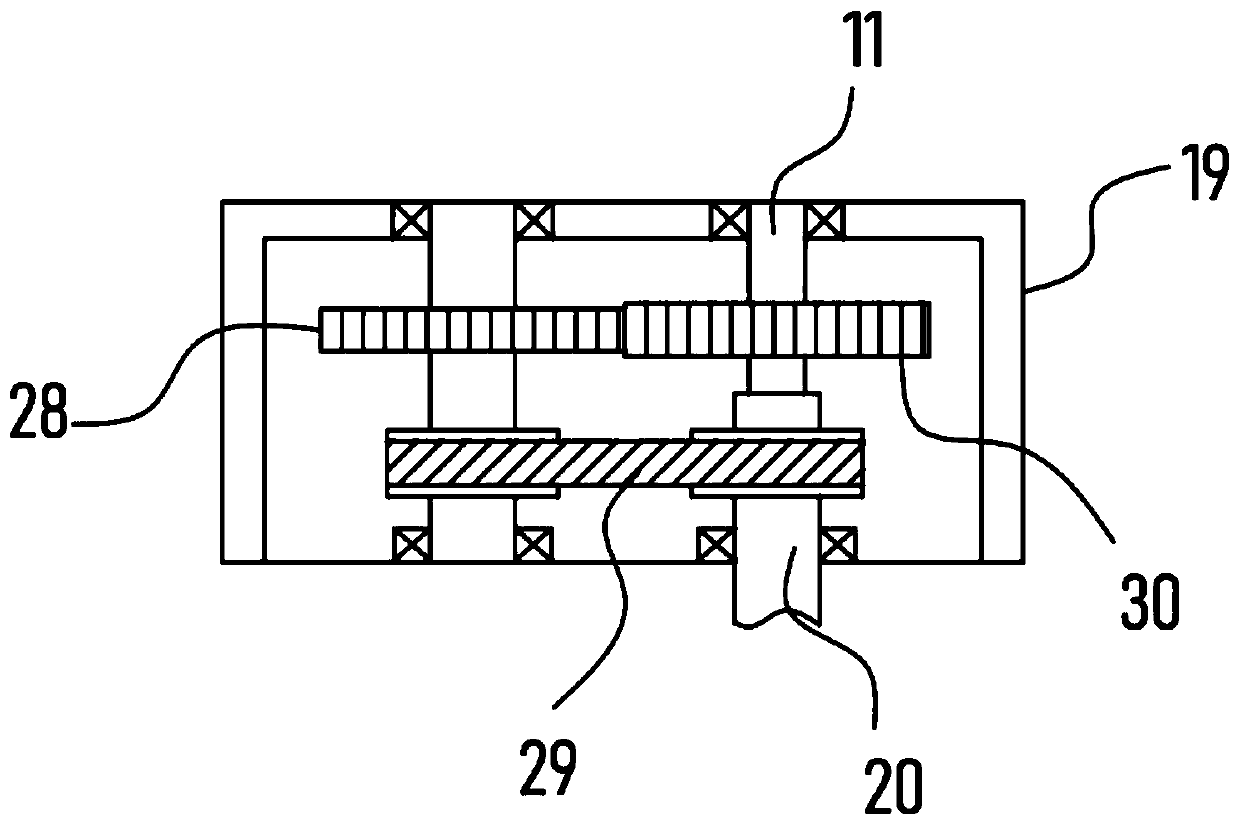

[0025] see Figure 1-4 , a shell painting device for electronic product processing, comprising a support frame 1, a paint box 17 is fixed on the support frame 1, it is characterized in that, a horizontally arranged support platform 24 is installed on the support platform 1 through a lifting mechanism, the support platform 24 is slidably installed with a delivery pump 32 driven by a lateral translation mechanism. The inlet end of the delivery pump 32 communicates with the paint tank 17 through the bellows 21. The outlet end of the delivery pump 32 is equipped with a paint sprayer 22. There is a clamping mechanism for vertically fixing the shell, a transmission box 19 is fixed on the support frame 1, a transmission mechanism is arranged in the transmission box 19, and a stirring mechanism located inside the paint box 17 is installed on the transmission mechanism. The frame 1 is provided with a linear reciprocating mechanism for driving the supporting platform 24 to lift vertical...

Embodiment 2

[0033] On the basis of Embodiment 1, in addition, the device is also provided with a linear reciprocating mechanism, which includes a biaxial motor I12 fixed on the bottom of the paint box 17, and an output shaft of the biaxial motor I12 is coaxially fixed with an incomplete bevel gear 10 , The bevel gear I8 and the bevel gear II9 which alternately mesh with the incomplete bevel gear 10 are sleeved on the screw mandrel 5 .

[0034] The double-axis motor I12 drives the incomplete bevel gear 10 to rotate, and the incomplete bevel gear 10 is meshed with the bevel gear I8 and the bevel gear II9 alternately. At this time, the screw rod 5 realizes clockwise and counterclockwise periodic rotation, thereby realizing the scissor brace The frame 7 drives the support table 24 to reciprocate vertically, that is, the paint spraying tray 22 can repeatedly and automatically spray paint on different vertical positions of the electronic product shell, which greatly improves the efficiency of pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com