Tool special for disposal of leaking oil of vent valve of main transformer radiator

A special tool and exhaust valve technology, which is applied in the field of electric power tools, can solve the problems of oil leakage from the exhaust valve of the main transformer radiator, increased power outage time and production costs, and transformer oil pollution on the work site, etc., and is easy to promote , low loss and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

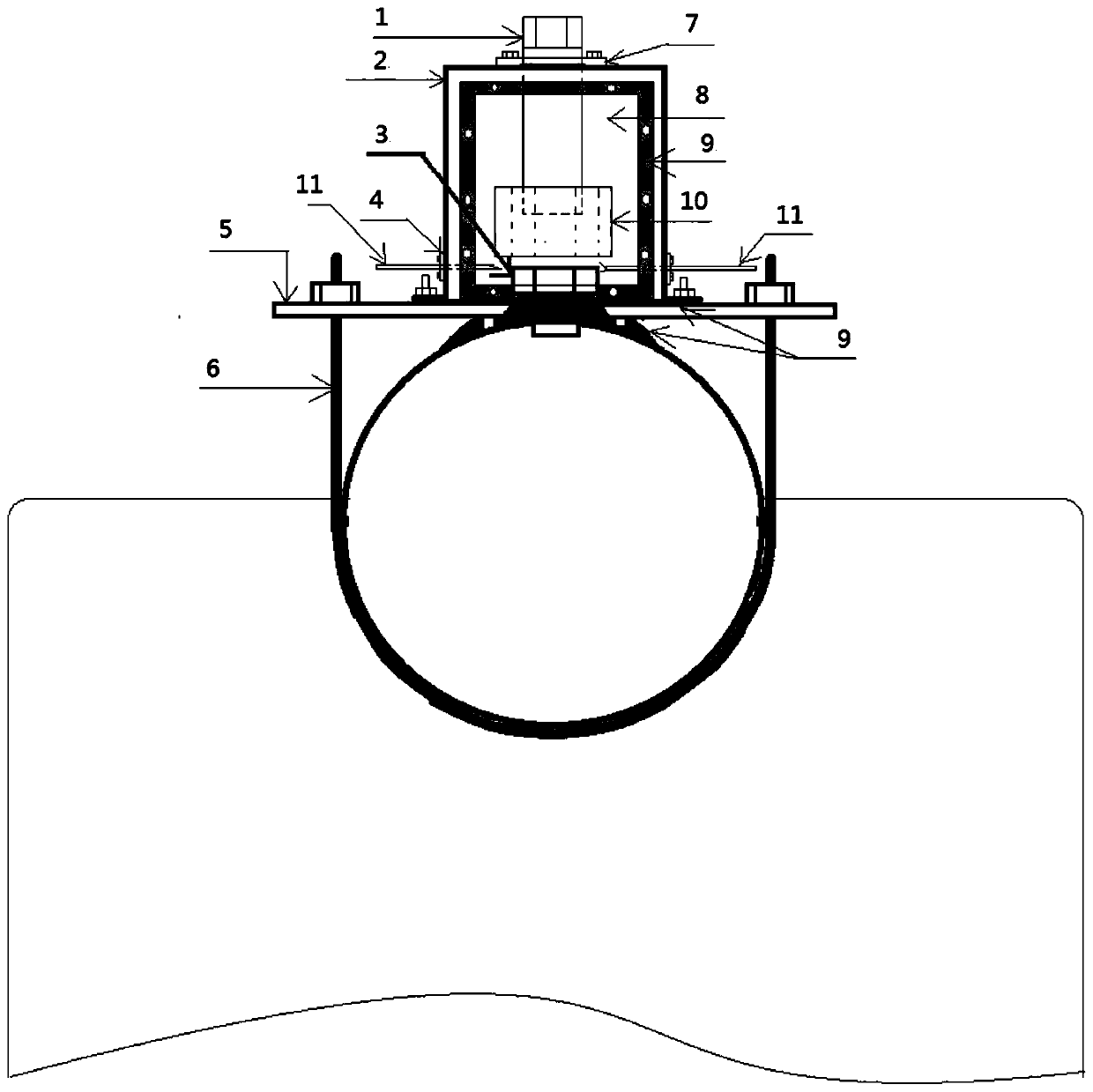

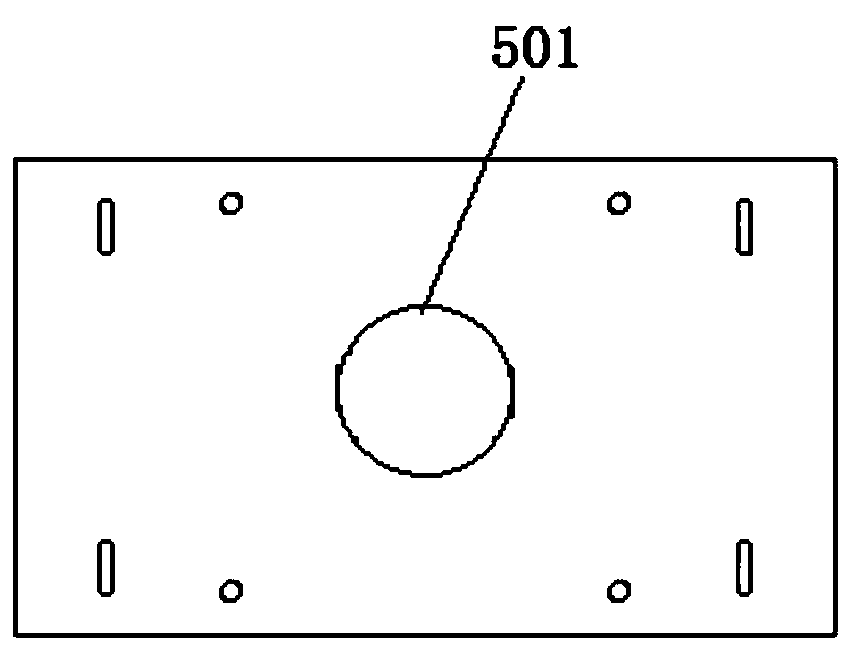

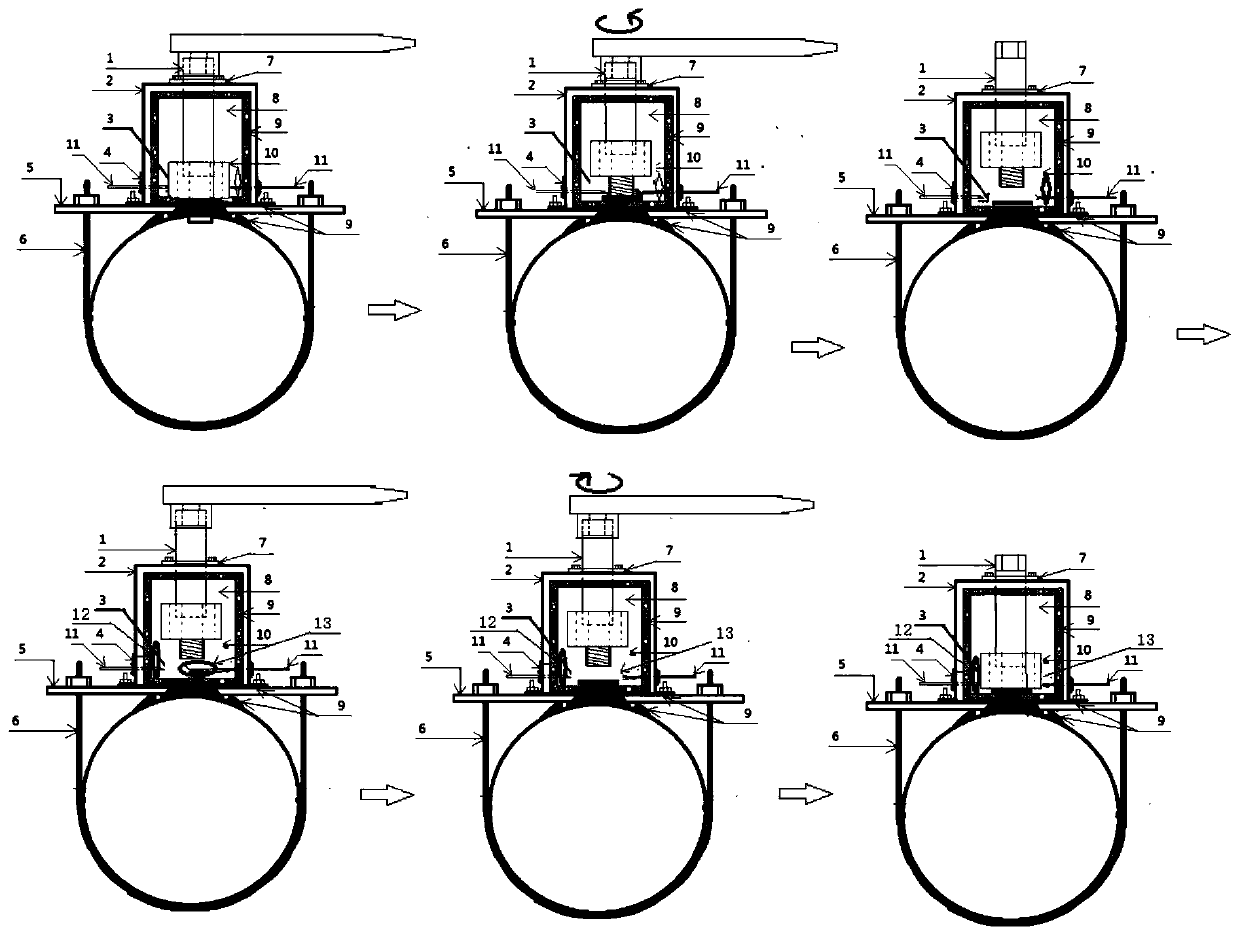

[0024] Such as figure 1 As shown, a special tool for oil leakage treatment of the main transformer radiator exhaust valve includes a sleeve operating rod 1, a protective cover 2, a fixing member 6 and a sealing ring operating rod 11, and the side wall of the protective cover 2 is provided with Transparent plexiglass 8, the upper end of protective cover 2 is connected with sleeve operating lever 1, and the lower end of described sleeve operating lever 1 is provided with sleeve 10, and described sleeve is located in protective cover 2, and sleeve operating lever 1 and The protective cover 2 is sealed and connected, the side wall of the protective cover 2 is sealed with a sealing ring operating rod 11, and the lower end of the protective cover 2 is sealed with the bottom plate of the protective cover 2, and the bottom plate of the protective cover 2 is provided. on the fixed fixture 6, such as figure 2 As shown, the bottom plate of the protective cover 2 is provided with a matc...

Embodiment 2

[0036] Such as Figure 4 As shown, the fixing member 6 in this embodiment is different from the first embodiment, the fixing member 6 includes a clamping plate 601, and the clamping plate 601 and the bottom plate of the protective cover 2 are connected by bolts.

[0037] When dealing with the square oil pipe exhaust valve (oil exhaust valve 3), it is enough to connect and fix the bottom plate of the protective cover 2 and the clamping plate 601 through long bolts, and the rest of the operations are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com