Construction method for replacing valve under pressure for liquid nitrogen freezing bridge plug

A valve replacement and liquid nitrogen freezing technology, which is applied in the field of oil and gas field exploration and development, can solve problems such as affecting operations, collision of excavation equipment wellhead gates, low freezing efficiency, etc., and achieve the effects of reducing operating time, improving freezing efficiency, and reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

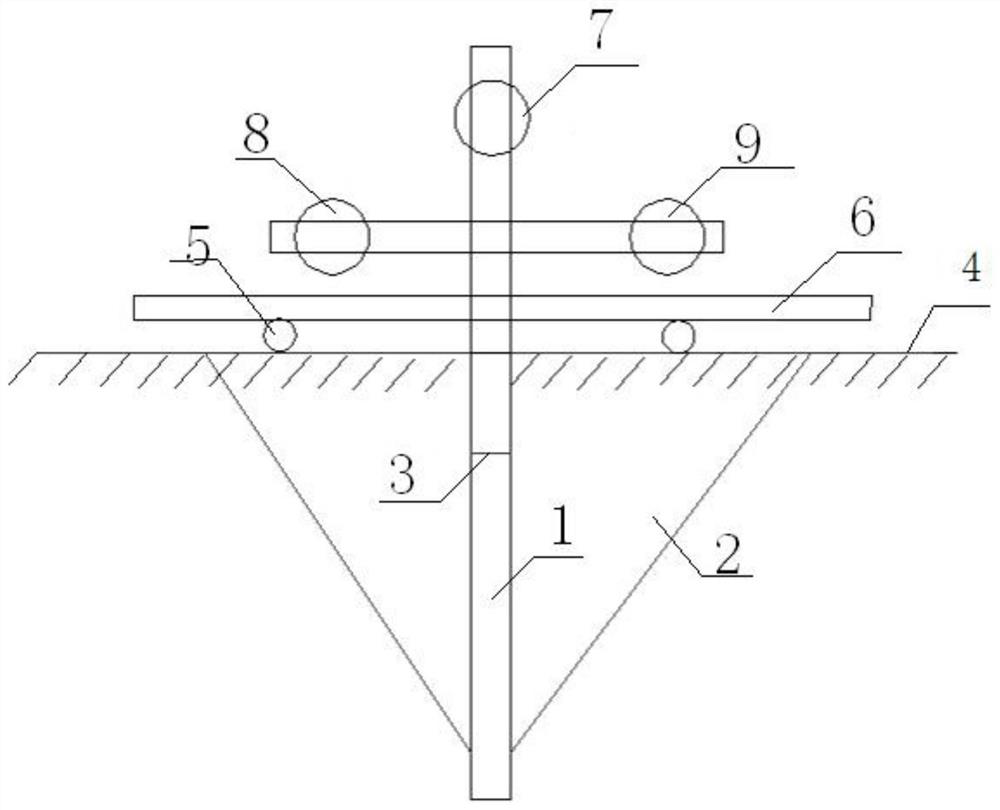

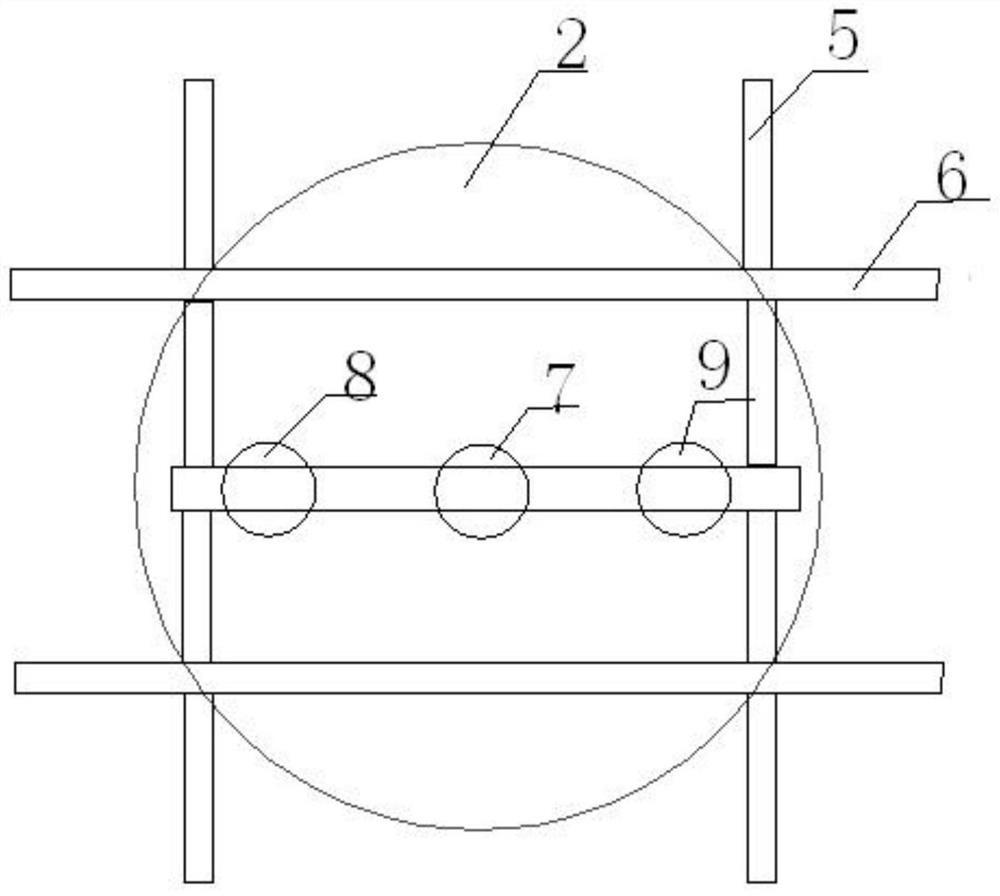

[0031] Such as Figure 1-2 As shown, a construction method for liquid nitrogen frozen bridge plug replacement valve under pressure includes the following steps:

[0032] 1) Take the casing 1 of the gas production wellhead where the valve is to be replaced as the center, and dig the liquid storage pit 2 toward the ground 4 in the circumferential direction;

[0033] 2) Mark the highest liquid level mark line 3 on the casing 1 in the liquid storage pit 2;

[0034] 3) Build a steel pipe skeleton on the ground 4 centering on the gas production wellhead where the valve is to be replaced;

[0035] 4) Install pedals on the steel pipe skeleton along the arrangement direction of the main control valves at the gas production wellhead;

[0036] 5) Inject liquid nitrogen into the liquid storage pit 2 until the liquid nitrogen liquid level reaches the highest liquid level mark line 3;

[0037] 6) Lay insulation pads on the pedals;

[0038] 7) making frozen bridge plugs;

[0039] 8) Rep...

Embodiment 2

[0043] On the basis of Example 1, the shape of the liquid storage pit 2 is conical with the tip pointing downward. The liquid storage pit 2 is conical, and the conical working space is used to directly contain the freezing medium, eliminating the freezing box, increasing the contact area between the freezing medium and the casing, and canceling the limited space of the working pit.

[0044] Further, the conical pit refers to a conical space with a diameter of 2.0m and a depth of 2.0m surrounding the casing 1 of the gas production wellhead, which is used to store liquid nitrogen, so that the amount of ground work is only 1 / 3 of the previous one, and the amount of freezing medium is 1 / 3. The effective volume is 4.26 times that of the previous one, and the freezing efficiency is high.

Embodiment 3

[0046] On the basis of Example 2, the distance between the highest liquid level marking line 3 and the ground 4 is ≥0.5m. Prevent the liquid nitrogen level from being too high to freeze the wellhead sealant and cause the wellhead seal to fail. The highest liquid level mark line is marked with red pigment, and the red mark is more eye-catching and easy to identify.

[0047] Further, after marking the highest liquid level mark line 3 in the step 2), it is necessary to spray liquid nitrogen on the conical slope in the liquid storage pit 2 . Use the liquid nitrogen output pipeline to evenly spray liquid nitrogen once on the conical slope 2, so that the slope is hardened and does not leak, and at the same time, solid phases such as soil clods do not fall, thereby improving construction safety.

[0048] Further, after the liquid nitrogen is sprayed on the tapered slope, liquid nitrogen needs to be uniformly sprayed around the casing 1 . Spray evenly around the casing 1 with liquid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com