Wood board edge banding device for table board production

A technology of edge banders and table boards, which is applied to other plywood/plywood appliances, wood processing appliances, household components, etc., and can solve the problems of energy consumption and inaccurate edge banding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

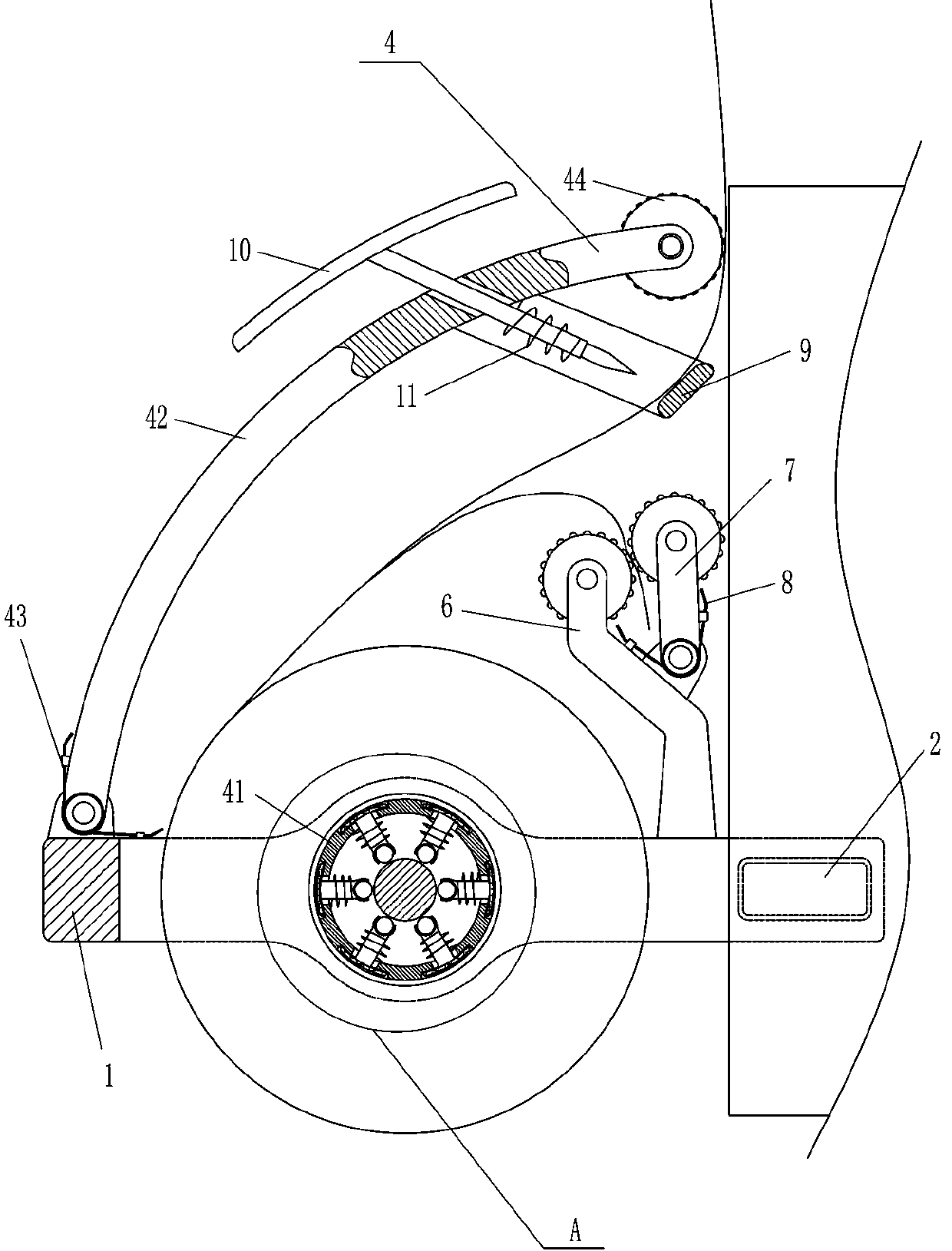

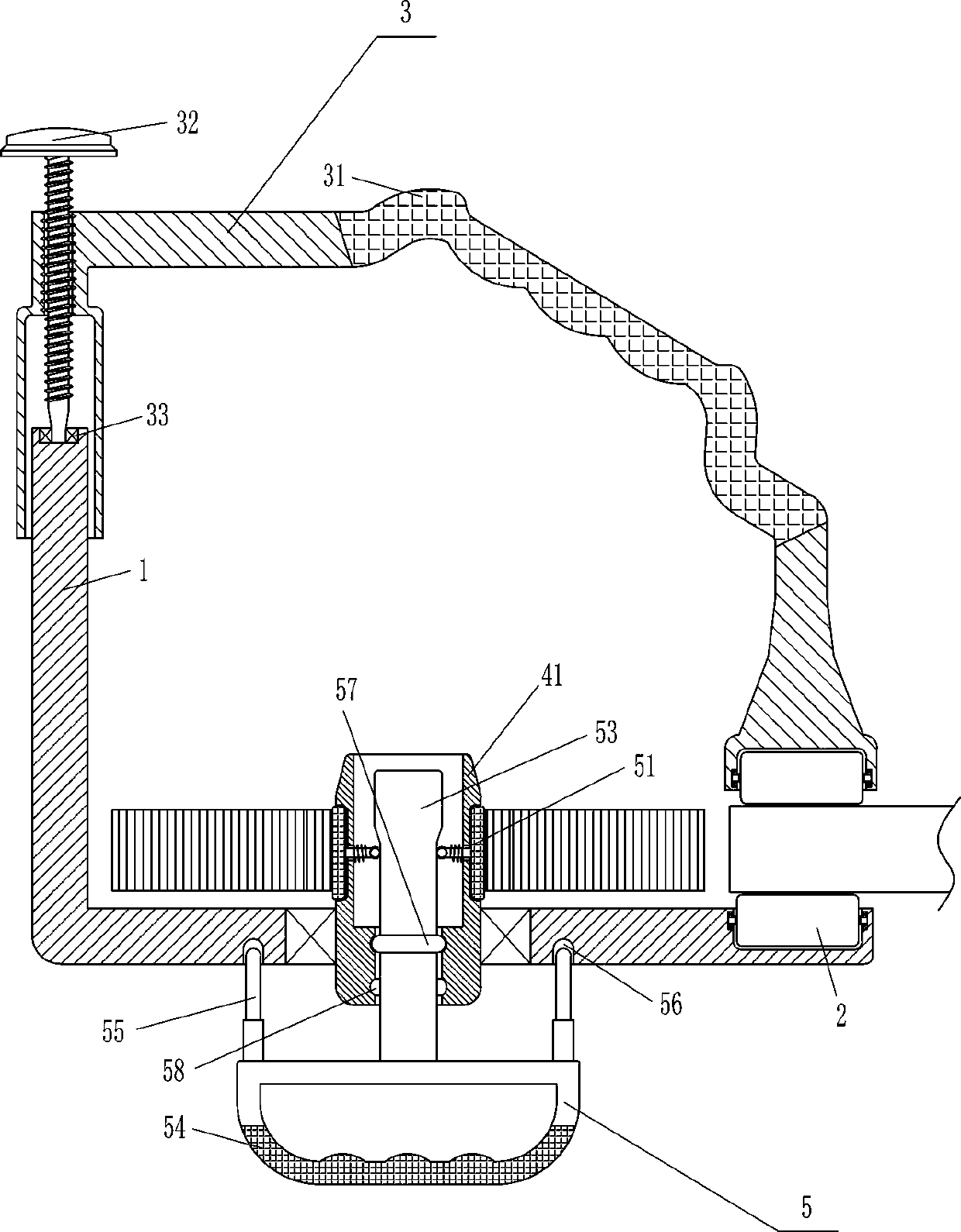

[0019] A wooden board edge bander for table board production, such as Figure 1-2 As shown, it includes an L-shaped plate 1, a guide roller 2, an adjustment device 3 and an edge banding device 4. The right side of the inner bottom of the L-shaped plate 1 is provided with a guide roller 2, and the upper left part of the L-shaped plate 1 is provided with an adjustment device. Device 3, the adjusting device 3 is used to adjust the gap between the device and the table board, the edge sealing device 4 is arranged in the middle of the L-shaped board 1, and the edge sealing device 4 is used to seal the table board.

[0020] The adjustment device 3 includes a special-shaped plate 31, a threaded knob 32 and a bearing 33. The lower end of the left part of the special-shaped plate 31 is a square opening, and the special-shaped plate 31 is sleeved on the left part of the L-shaped plate 1 through the square opening. The guide roller 2 is provided in the way, the left part of the L-shaped p...

Embodiment 2

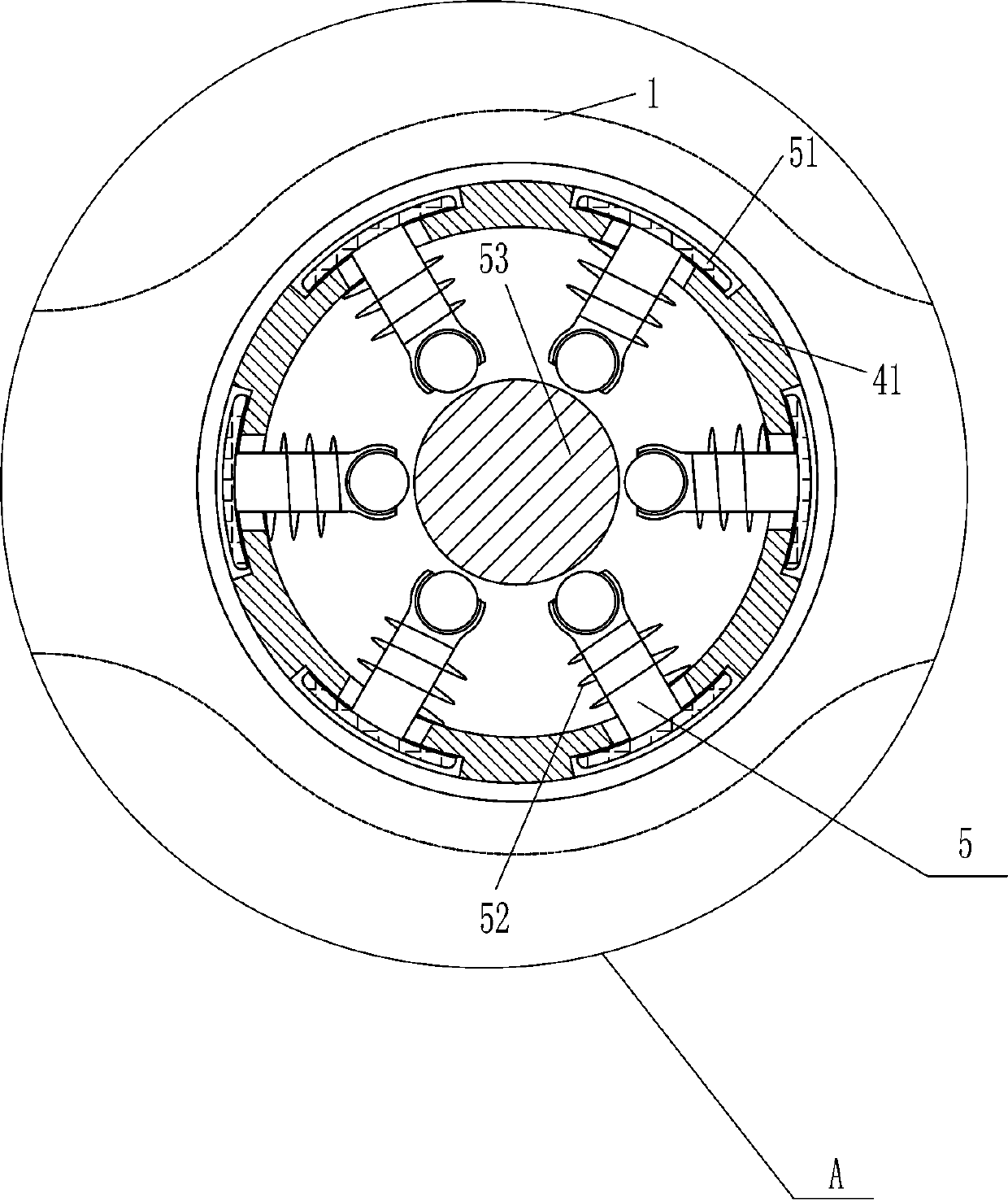

[0024] On the basis of Example 1, such as Figure 1-3 As shown, the fastening device 5 includes a T-shaped bar 51, a first spring 52, a special-shaped cylindrical block 53, a handle 54, an insertion rod 55 and a limit protrusion ring 57, and the hollow cylinder 41 is evenly spaced with T-shaped A rod 51, a first spring 52 is connected between the T-shaped rod 51 and the hollow cylinder 41, and a special-shaped cylindrical block 53 is slidably arranged in the hollow cylinder 41, and the T-shaped rod 51 contacts and cooperates with the special-shaped cylindrical block 53, The special-shaped cylindrical block 53 passes through the hollow tube 41, and a handle 54 is installed on the bottom of the special-shaped cylindrical block 53. Two inserting rods 55 are welded on the handle 54. Two card slots 56 are opened at the bottom of the L-shaped plate 1. The rod 55 cooperates with the clamping groove 56, and the special-shaped cylindrical block 53 is provided with a limiting raised rin...

Embodiment 3

[0027] On the basis of Example 2, such as figure 2 As shown, it also includes a fixed roller bar 6, a movable roller bar 7 and a second torsion spring 8, and the rear side of the right part of the L-shaped plate 1 is provided with a fixed roller bar 6 in a bolt-connected manner. A movable roller bar 7 is provided in a rotating manner, and the movable roller bar 7 is connected with the fixed roller bar 6 to be provided with a second torsion spring 8 .

[0028] It also includes a U-shaped frame 9, a T-shaped cutter 10 and a second spring 11. The inner side of the arc bar 42 is fixedly connected with the U-shaped frame 9, and the arc-shaped bar 42 is slidably provided with a T-shaped cutter 10. A second spring 11 is connected between the T-shaped cutter 10 and the arc bar 42 , and the T-shaped cutter 10 cooperates with the U-shaped frame 9 .

[0029] The operator peels off the release paper and places it between the fixed roller 6 and the movable roller 7. When the movable roll...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap