A direct-drive coaxial rotor system with two steering gears and its control strategy

A technology of rotor and steering gear, which is applied in the field of helicopters, can solve the problems of poor wind resistance and insufficient control force, and achieve the effect of high wind resistance, simple structure, and less number of steering gears

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

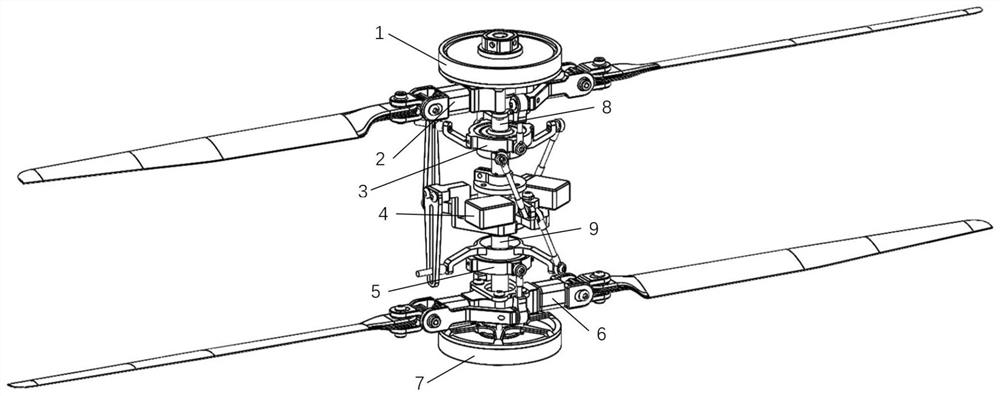

[0028] like figure 1 Shown is a coaxial rotor system directly driven by two steering gears, the upper rotor power module 1 is at the top of the coaxial dual rotor system. The upper rotor assembly 2 is installed under the upper rotor power module 1, the upper tilting mechanism 3 is installed under the upper rotor assembly 2, the driving servo group assembly 4 is installed under the upper tilting mechanism 3, and the lower tilting mechanism 5 is installed under the drive Below the steering gear group assembly 4 , the lower rotor assembly 6 is installed below the lower tilting mechanism 5 , and the lower rotor power module 7 is installed below the lower rotor assembly 6 .

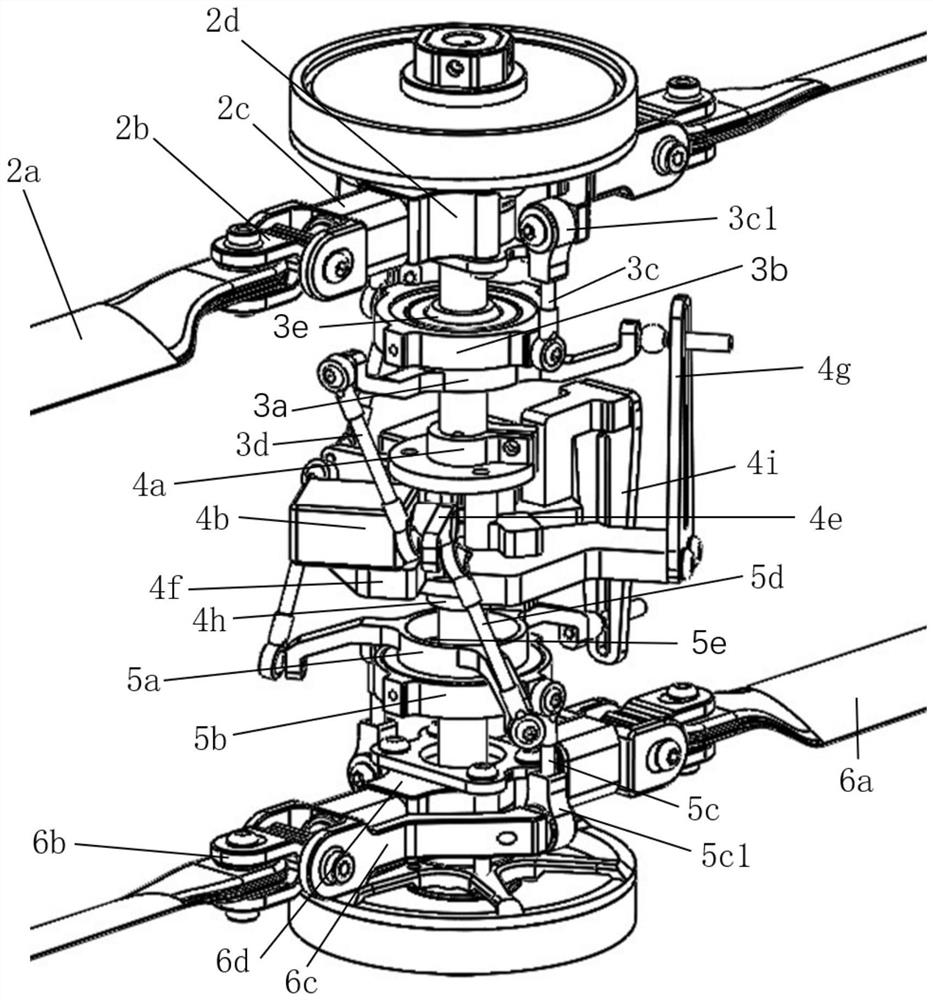

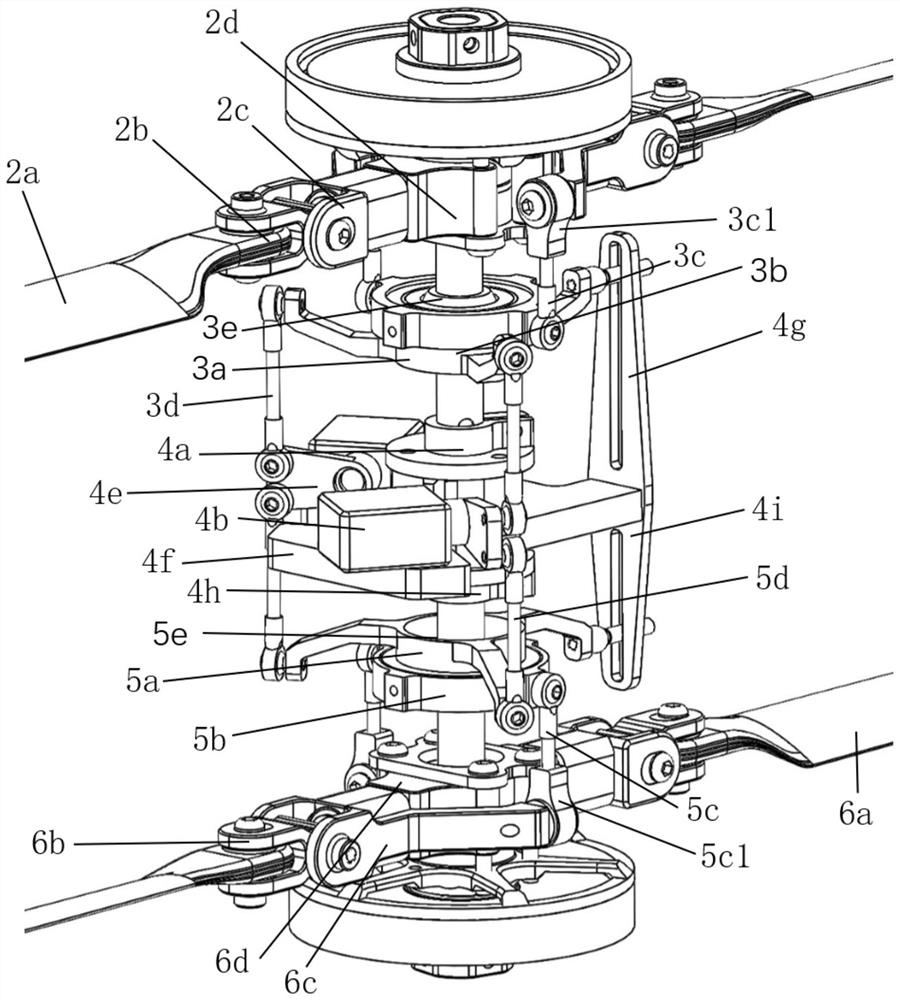

[0029] like figure 2, shown in 3 includes an upper rotor power module 1, an upper rotor assembly 2, an upper tilting mechanism 3, a driving servo group assembly 4, a lower tilting mechanism 5, a lower rotor assembly 6, a lower rotor power module 7, and an upper fixed main shaft 8, lower fixed main shaft 9. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com