A carrier circulation conveying device and its use method

A conveying device and cyclic conveying technology, applied in conveyors, mechanical conveyors, conveyor objects, etc., can solve the problems of wasting manpower and increasing labor costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

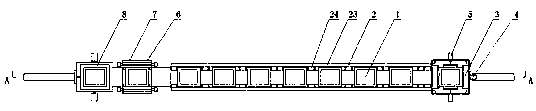

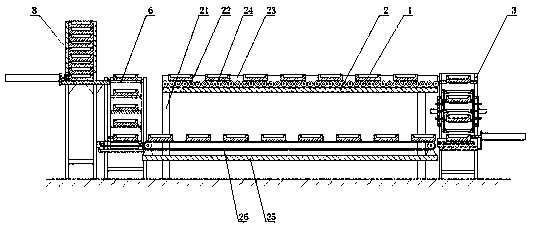

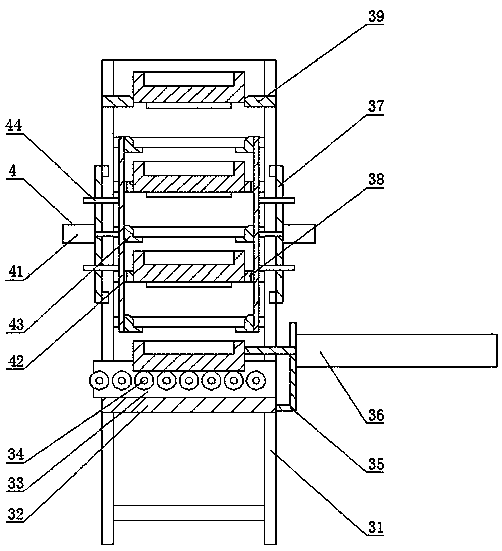

[0037] The embodiment of the present invention provides a carrier circulation conveying device and its use method, by placing the carrier 1 flowing out of the conveying device 2 in the blanking device 3, and using the blanking device 3 to transport the carrier 1 to the belt conveyor A26 , and then transport the carrier 1 to the material lifting device 6 by the belt conveyor A26, and finally send the carrier 1 back to the conveying device 2 by the material lifting device 6, so as to complete the automatic circular transport of the carrier 1 and solve the problem of current consumer electronics products In the process of manual assembly production, the problem of wasting manpower and increasing labor costs due to the excessive number of manual transport vehicles. Through the above-mentioned design of the blanking device 3, the carrier 1 can be slowly dropped to the roller B34 layer by layer through the retaining claws 43, so as not to damage the carrier, and the design has a comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com