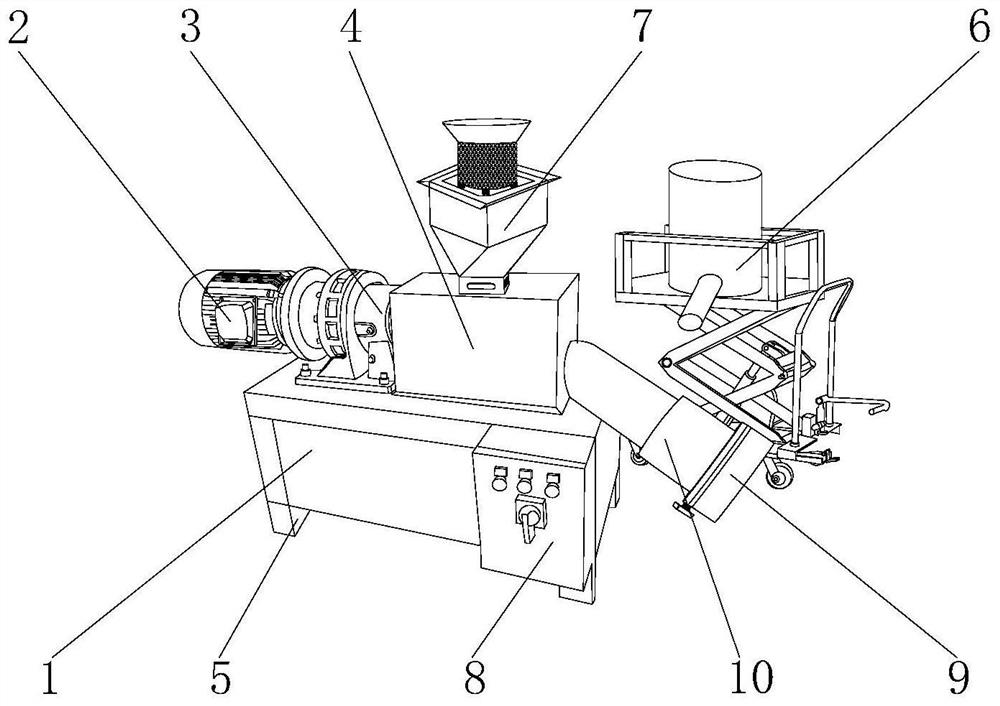

A high-efficiency powder adding device for producing wire and cable

A powder adding device, wire and cable technology, applied in the direction of loading/unloading, transportation and packaging, solid separation, etc., can solve the problems that powder cannot be added to the mixing box, the effect of powder addition, and screening cannot be realized, so as to save manpower , increase the working effect and facilitate the feeding operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

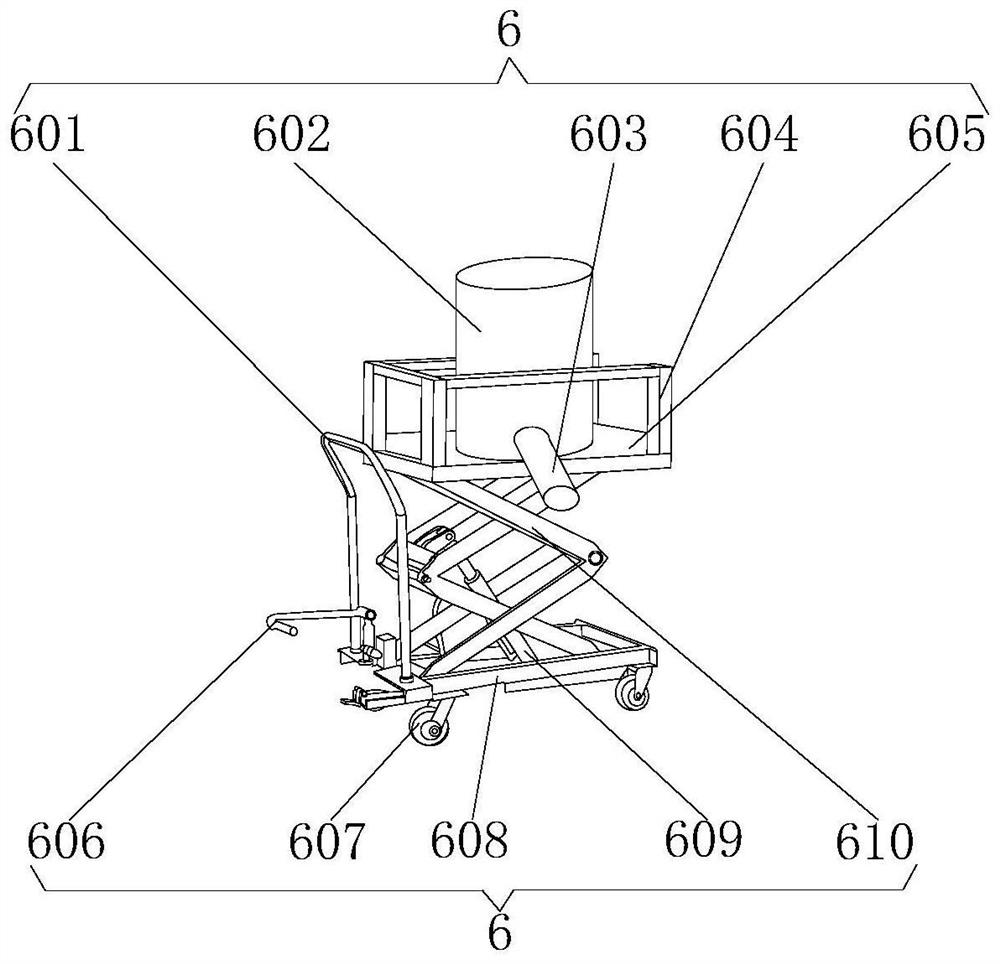

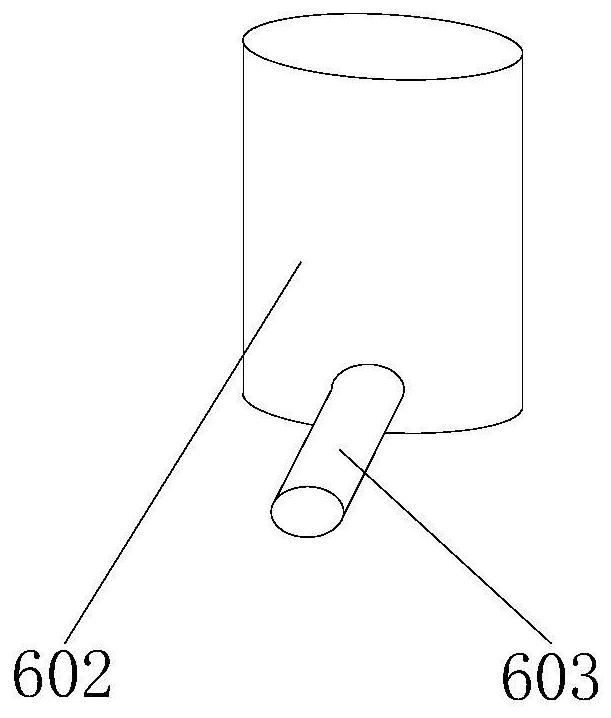

[0026] Embodiment one: if figure 2 , 3 As shown, the mobile lifting feeding mechanism 6 includes a push rod 601, a charging barrel 602, a discharge port 603, a guardrail 604, a placement plate 605, an adjustment pedal 606, a universal wheel 607, a support frame 608, a cylinder 609, and a lifting frame 610, the universal wheel 607 is located around the lower end of the support frame 608, the push rod 601 and the adjustment pedal 606 are located on one side of the support frame 608, the lifting frame 610 is located at the upper end of the support frame 608, and the cylinder 609 is located on one side of the lifting frame 610. The plate 605 is located at the upper end of the lifting frame 610, the charging bucket 602 and the guardrail 604 are positioned at the upper end of the placing plate 605, the discharge port 603 is positioned at the outer wall of the charging bucket 602, and the upper end outer surface of the supporting frame 608 passes through the cylinder 609, the liftin...

Embodiment 2

[0027] Embodiment two: if Figure 4 , 5As shown, the adjustable feed screening and filtering mechanism 7 includes a baffle plate 701, a filter screen 702, a feed hopper 703, a vibration spring 704, a deck 705, a feed funnel 706, a slide rail 707, a pull groove 708, and an adjustment plate 709, The feed funnel 706 is located at the lower end of the card seat 705, the adjustment plate 709 is located inside the feed funnel 706, the pull groove 708 is located at the front end of the adjustment plate 709, the slide rails 707 are located on both sides of the adjustment plate 709, and the baffle plate 701 is located at the card seat 705 around, the vibrating spring 704 is located at the upper end of the deck 705, the filter screen 702 is located at the upper end of the vibrating spring 704, the feed hopper 703 is located at the upper end of the filter screen 702, and the outer surface of the lower end of the filter screen 702 passes through the vibrating spring 704 and the deck 705. ...

Embodiment 3

[0028] Embodiment three: as Figure 6 , 7 As shown, the discharge control butterfly valve mechanism 9 includes a control valve 901, a regulator 902, a pipe wall 903, a disc valve disc 904, and a self-cleaning layer 905, the regulator 902 is located on the outer wall of the control valve 901, and the pipe wall 903 is located On one side, the disc valve disc 904 is located on the inner wall of the pipe wall 903, and the self-cleaning layer 905 is located on the outer surface of the disc valve disc 904. A rotating shaft is arranged between the control valve 901 and the pipe wall 903, and one side of the control valve 901 passes through the rotating shaft. It is movably connected with one side of the pipe wall 903, superglue is set between the disc valve disc 904 and the self-cleaning layer 905, the outer surface of the disc valve disc 904 is fixedly connected with the outer surface of the self-cleaning layer 905 through super glue, and through the control valve 901 and regulator...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com