Semi-automatic lifting device

A lifting device, semi-automatic technology, applied in the direction of lifting device, lifting frame, food science, etc., can solve the problems of high production cost of driving equipment, increased operating cost, large energy consumption, etc., and achieves simple structure, easy release, and low failure rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

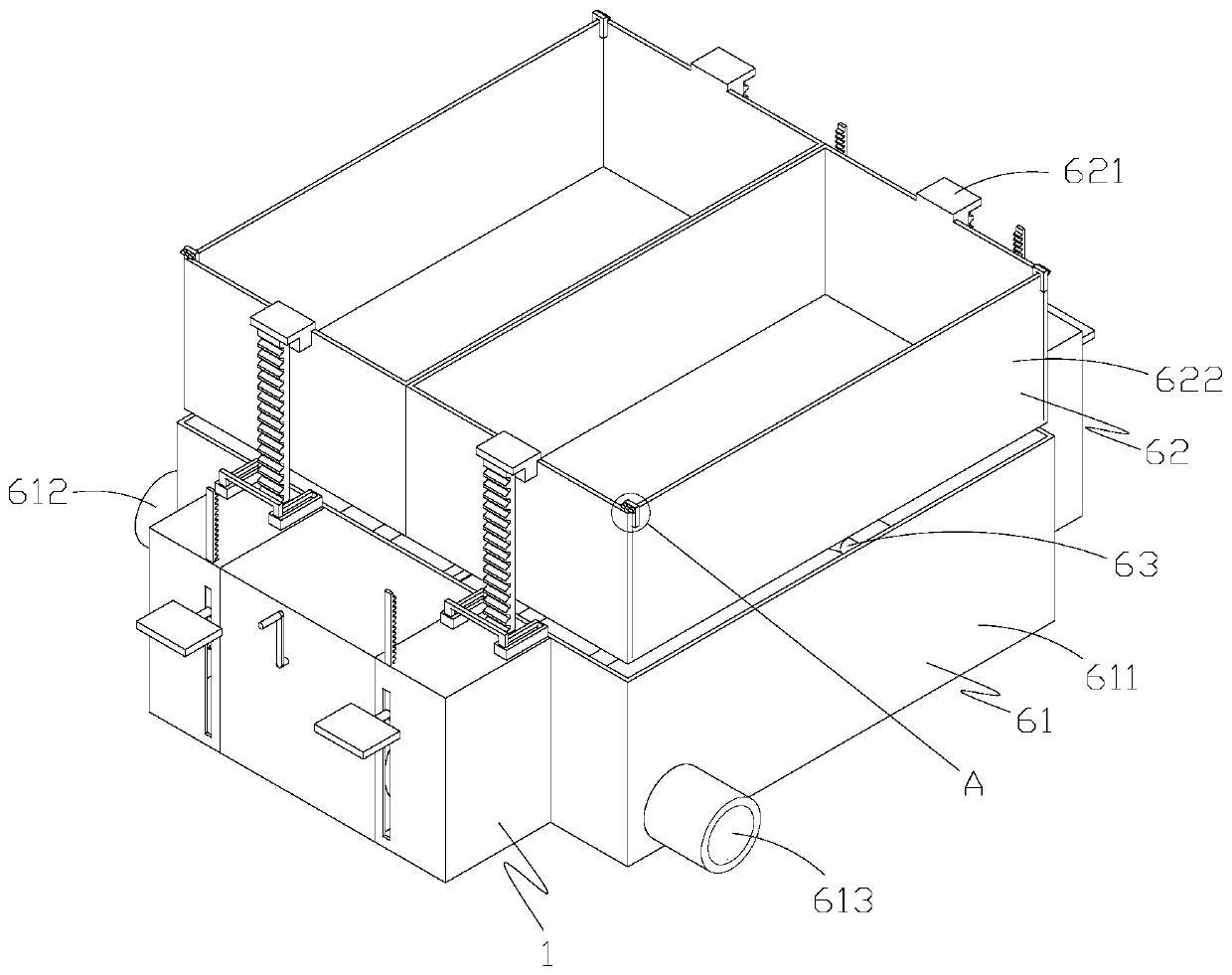

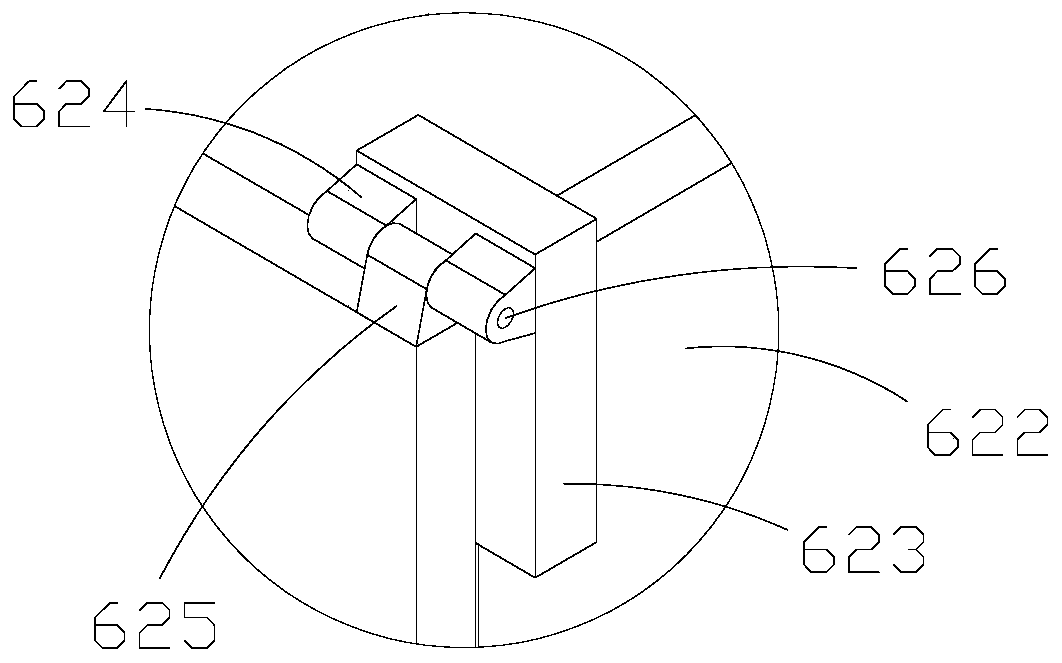

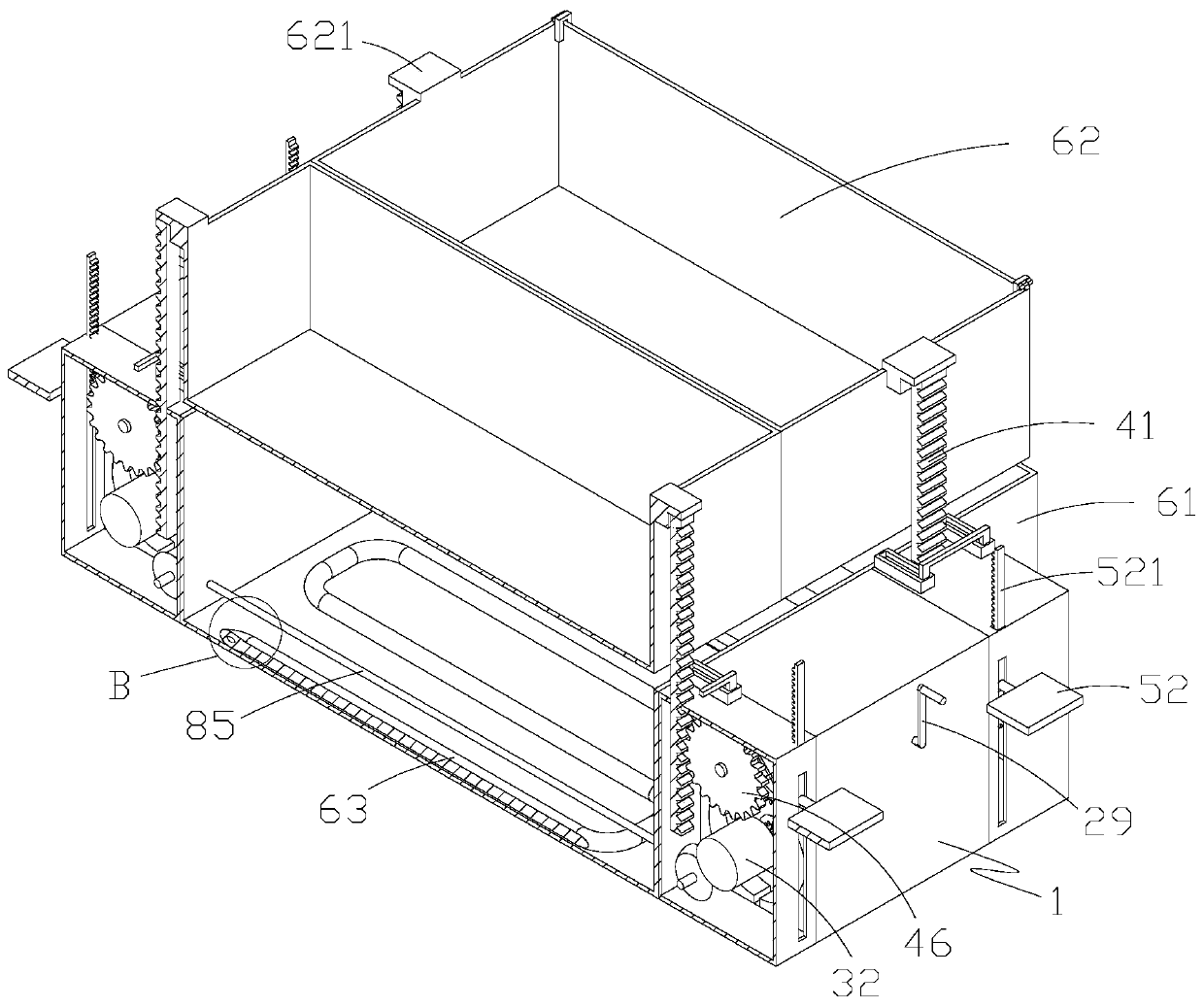

[0029] Such as figure 1 As shown, a semi-automatic lifting device includes a housing 1, a first lifting structure, a first driving structure, a first clamping structure, an energy storage structure, a selection switch structure, a second clamping structure, a second lifting structure and a first Two driving structures; wherein the structure of the first lifting structure is the same as that of the second lifting structure, the structure of the first driving structure is the same as that of the second driving structure, the structure of the first clamping structure is the same as that of the second clamping structure, and the above three pairs of structures Relative to the energy storage structure, they are arranged symmetrically in pairs.

[0030] Specifically, the energy storage structure includes a storage cylinder 21, a first insertion cylinder 22, a second insertion cylinder 23, a storage shaft 24 and an energy storage member 25; , a chute 11 is opened in the housing 1, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com