A polymer and wash-resistant fabric water repellent

A technology of polymers and waterproofing agents, applied in the direction of plant fibers, textiles, papermaking, and liquid-repellent fibers, etc., can solve problems such as weak washing resistance, increased waterproofing agents, and loss of water and oil repellent functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

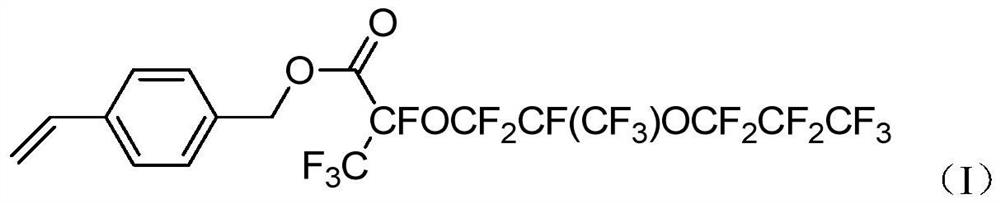

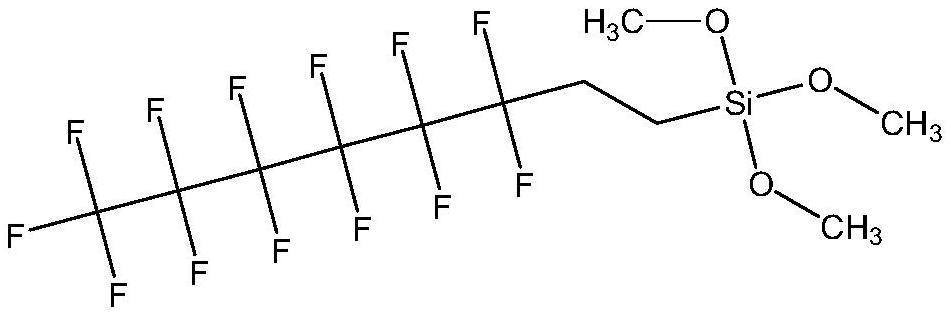

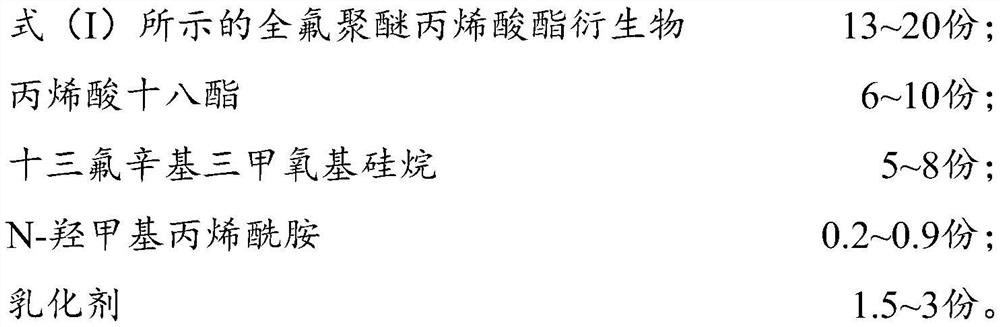

[0046] The present embodiment provides a kind of polymer, and its preparation method is as follows:

[0047] Weigh out 7.7 g of the compound represented by the formula (I), 3.85 g of methyl methacrylate, 3.025 g of tridecafluorooctyltrimethoxysilane, 0.165 g of N-methylol acrylamide, and octadecyltrimethyl 0.165g of ammonium chloride, 0.33g of S-80 emulsifier, 0.33g of L-64 emulsifier, 0.33g of Tween-20 emulsifier, 2.2g of tripropylene glycol, and 36.74g of deionized water were placed in a four-necked flask and heated to 55 ℃, stirring until the solid dissolves, and the dissolved solution is emulsified and homogenized to obtain a pre-emulsion. Continue to heat to 67°C, stir evenly, and then add 0.165 g of azodiisobutylamidine dihydrochloride and deionized water, and keep the reaction for 7 hours to obtain the result.

[0048] The polymers provided in this example can be directly used as fabric water repellants.

Embodiment 2

[0050] The present embodiment provides a kind of polymer, and its preparation method is as follows:

[0051] Weigh out 9.35 g of the compound represented by the formula (I), 3.85 g of methyl methacrylate, 3.575 g of tridecafluorooctyltrimethoxysilane, 0.275 g of N-methylol acrylamide, and octadecyltrimethyl Ammonium chloride 0.22g, S-80 emulsifier 0.3025g, L-64 emulsifier 0.3025g, Tween-20 emulsifier 0.3025g, tripropylene glycol 2.75g, deionized water 33.88g in a four-necked flask, heated to 55 ℃, stirring until the solid dissolves, and the dissolved solution is emulsified and homogenized to obtain a pre-emulsion. Continue to heat to 67° C., stir evenly, then add 0.1925 g of azodiisobutylamidine dihydrochloride and deionized water, and keep the reaction for 7 h to obtain the result.

[0052] The polymers provided in this example can be directly used as fabric water repellants.

Embodiment 3

[0054] The present embodiment provides a kind of polymer, and its preparation method is as follows:

[0055] Weigh out 11 g of the compound represented by the formula (I), 3.41 g of octadecyl acrylate, 3.3 g of tridecafluorooctyltrimethoxysilane, 0.11 g of N-methylol acrylamide, and octadecyltrimethyl chloride Ammonium 0.165g, S-80 emulsifier 0.33g, L-64 emulsifier 0.33g, Tween-20 emulsifier 0.33g, tripropylene glycol 2.75g, deionized water 33g were placed in a four-necked flask, heated to 55°C, stirred , until the solid dissolves, and the dissolved solution is emulsified and homogenized to obtain a pre-emulsion. Continue to heat to 67° C., stir evenly, then add 0.275 g of azodiisobutylamidine dihydrochloride and deionized water, and keep the reaction for 7 hours.

[0056] The polymers provided in this example can be directly used as fabric water repellants.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com