High-pressure main steam valve of steam turbine

A main steam valve and steam turbine technology, applied in mechanical equipment, engine components, machines/engines, etc., can solve problems such as failure of pre-opening valve action, oxidation of sliding mating surfaces, and increased workload, so as to isolate the impact and improve the The effect of stability and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

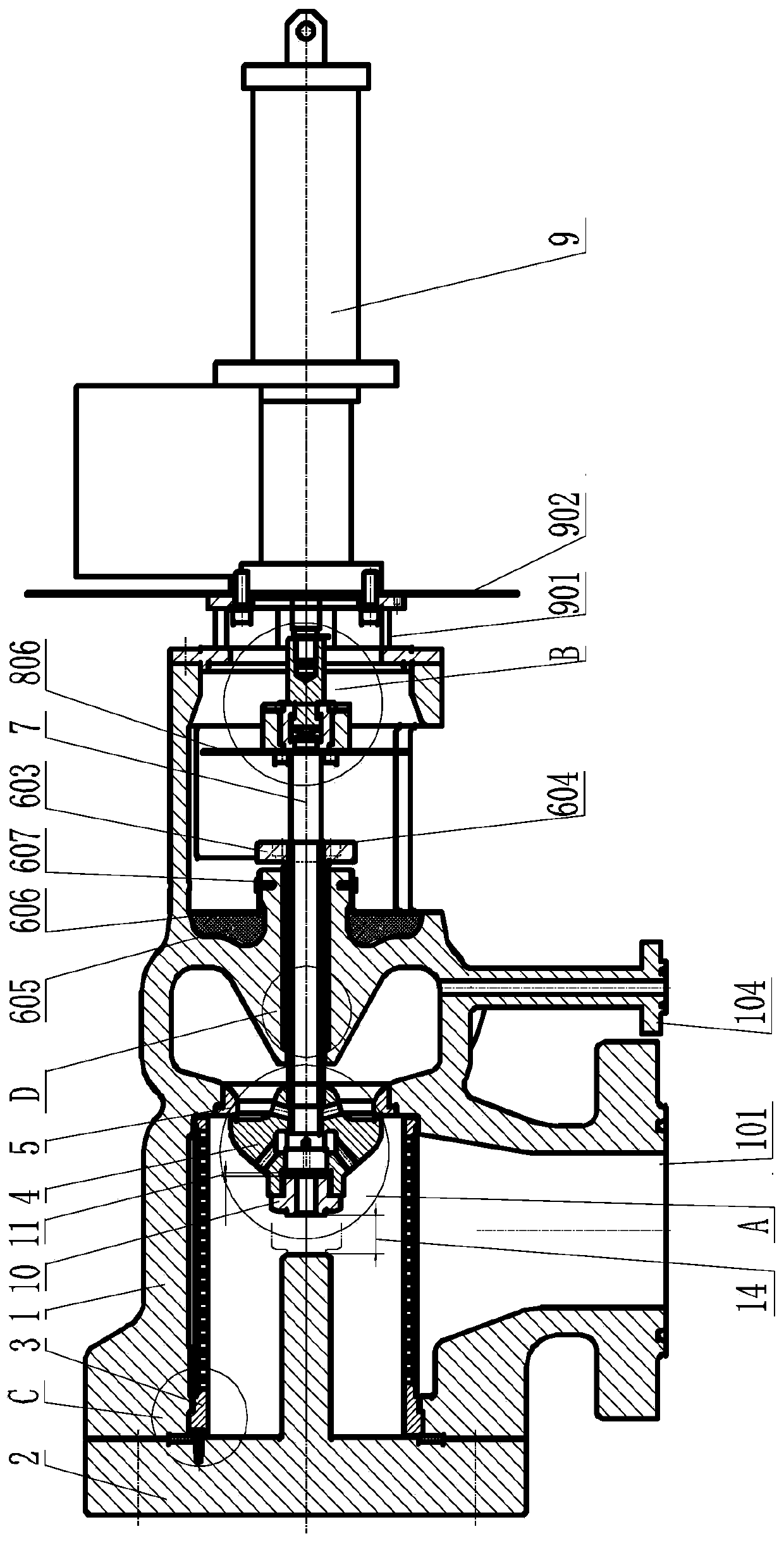

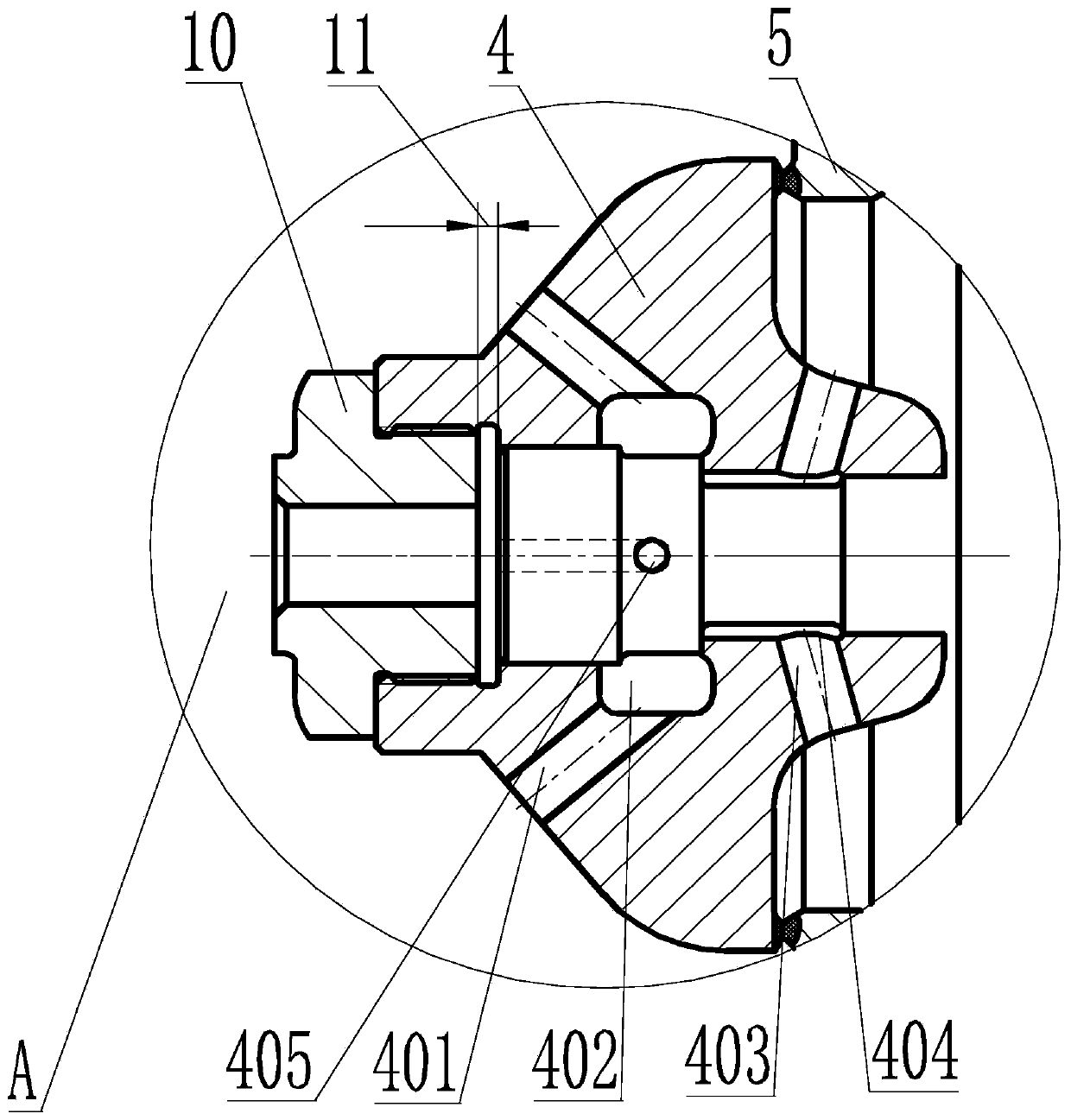

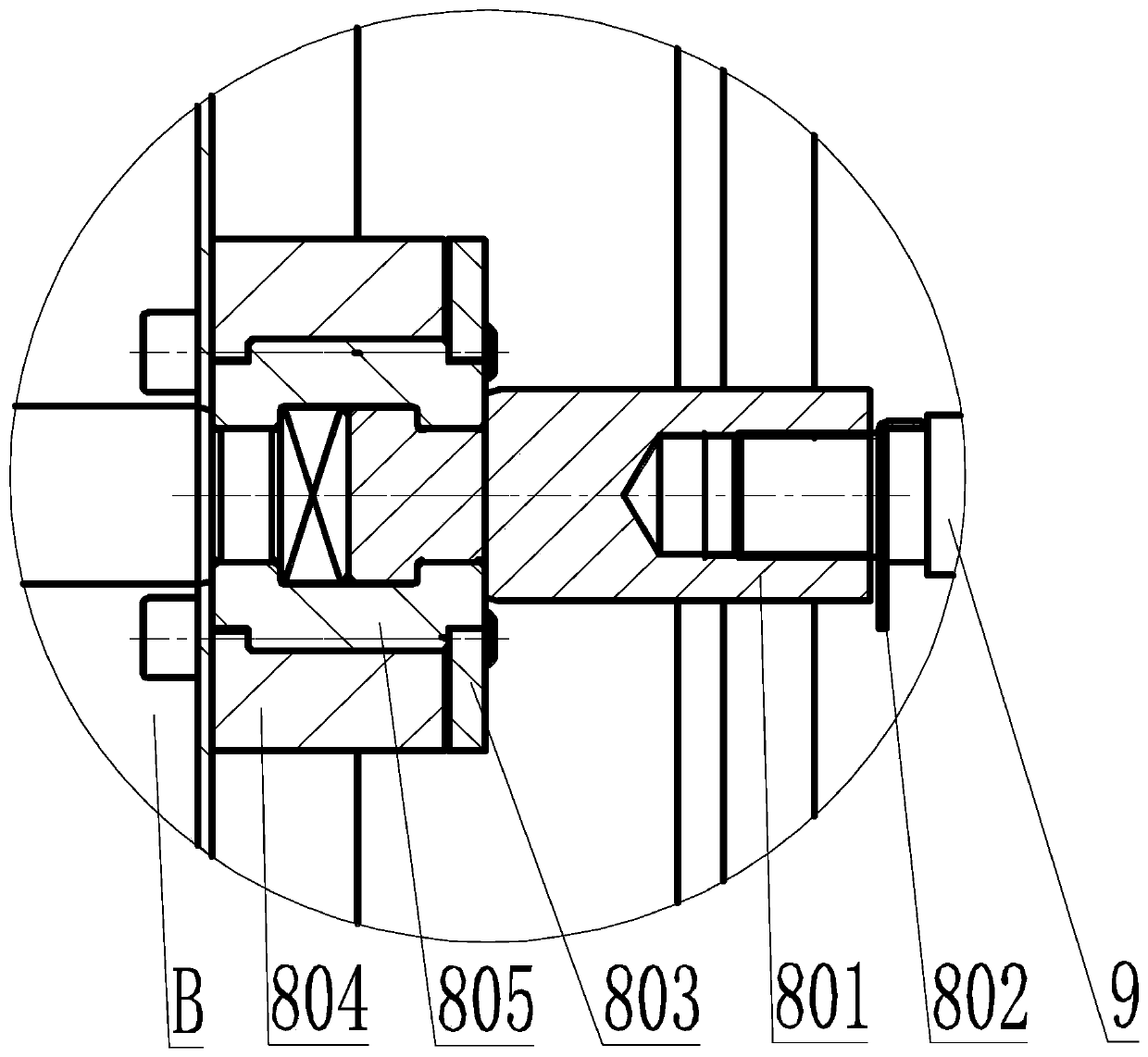

[0044] Such as Figure 1-6 As shown in the figure, a high-pressure main steam valve of a steam turbine is installed on the reaction steam turbine, and is responsible for controlling the output of the steam delivered by the boiler to the main steam regulating valve for adjustment. The function of cutting off the steam inlet of the steam turbine unit includes valve body 1, valve cover 2, filter screen assembly 3, main steam valve disc 4 and valve stem 7.

[0045] The valve body 1 is a hollow cavity inside, and the left and right ends of the horizontal axis of the valve body 1 are both open, and the bottom of the left side of the valve body 1 is provided with a steam inlet 101 for introducing steam. In order to enhance the stability of the high-pressure main steam valve in operation, a main steam valve bracket interface 102 is provided on the side of the steam inlet 101 of the valve body 1, and is fixedly connected with the bottom bracket of the steam turbine to fix the high-pres...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap