Tooling equipment

A technology for tooling equipment and workpieces, which is applied in the field of tooling equipment, can solve problems such as deterioration of tooling equipment positioning accuracy, poor economic efficiency, and poor repeat positioning stability, and achieve good repeat positioning stability, reduce production costs, and improve assembly quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

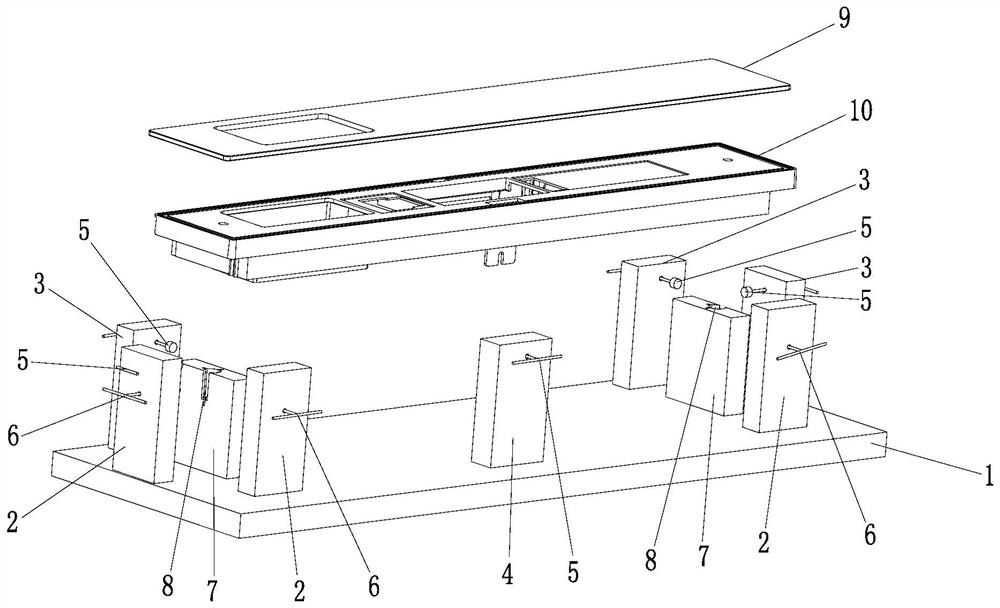

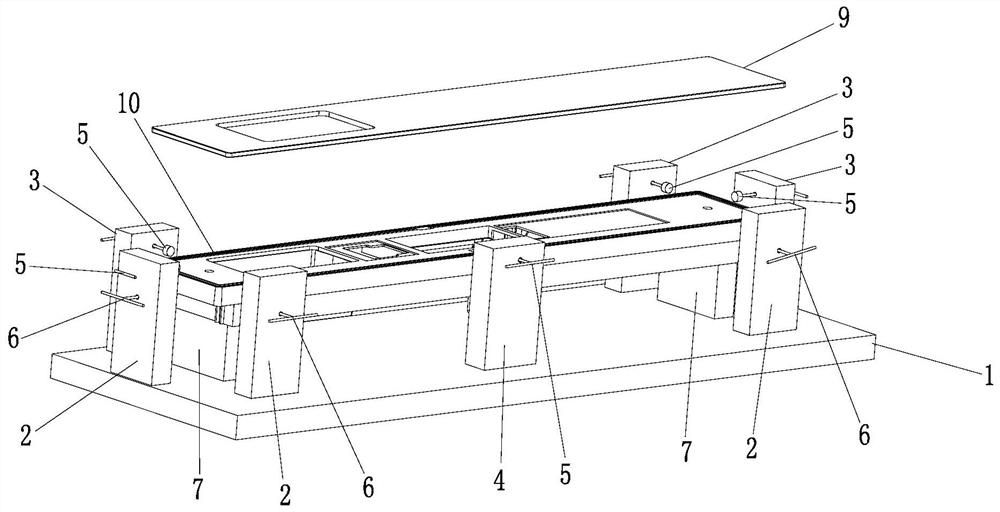

[0031] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, not to limit the present invention.

[0032] The work equipment according to the present invention will be described below with reference to the drawings.

[0033] Such as figure 1 and figure 2 As shown, the exemplary embodiment of the present invention provides a kind of tooling equipment, and this tooling equipment is used for positioning and installing workpieces, and wherein workpieces comprise upper workpiece 9 and lower workpiece 10 that are stacked and assembled up and down, for example, upper workpiece 9 can be micro-steamed The glass plate used for appearance decoration in the oven integrated machine, the workpiece 10 below can be the control box in the micro steam oven integrated machine, and the glass ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap