Thrust rod testing machine

A thrust rod and testing machine technology, which is applied in vehicle testing, mechanical parts testing, machine/structural parts testing, etc., can solve problems affecting the use of thrust rods and large errors in experimental results, so as to achieve realistic and accurate simulation results. Simulate the situation comprehensively and reduce the effect of error

Active Publication Date: 2020-04-10

烟台辰宇汽车部件有限公司

View PDF10 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] The above-mentioned simulation experiment device only simulates and detects the two torsion directions of the thrust rod, and the vehicle will vibrate up and down during actual driving, which will affect the use of the thrust rod. Therefore, the error of the experimental results of the above-mentioned simulation experiment device is relatively large

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

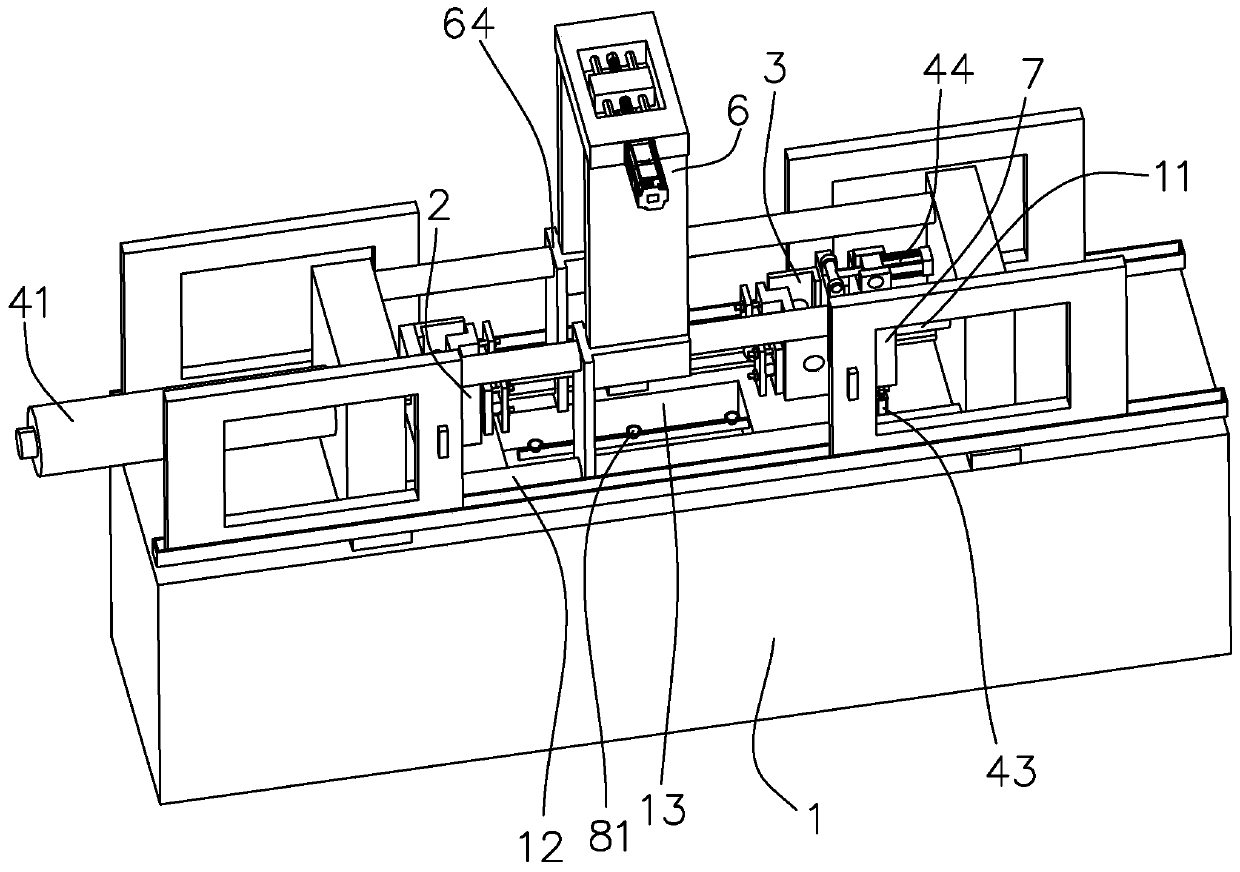

[0038] A thrust rod testing machine such as figure 1 As shown in the figure, it includes a body 1 arranged in the shape of "凵", the two ends of the body 1 are respectively equipped with boom 1 2 and boom 2 3, and the thrust rod is installed between the boom 1 2 and boom 2 3, and the simulation test is carried out .

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

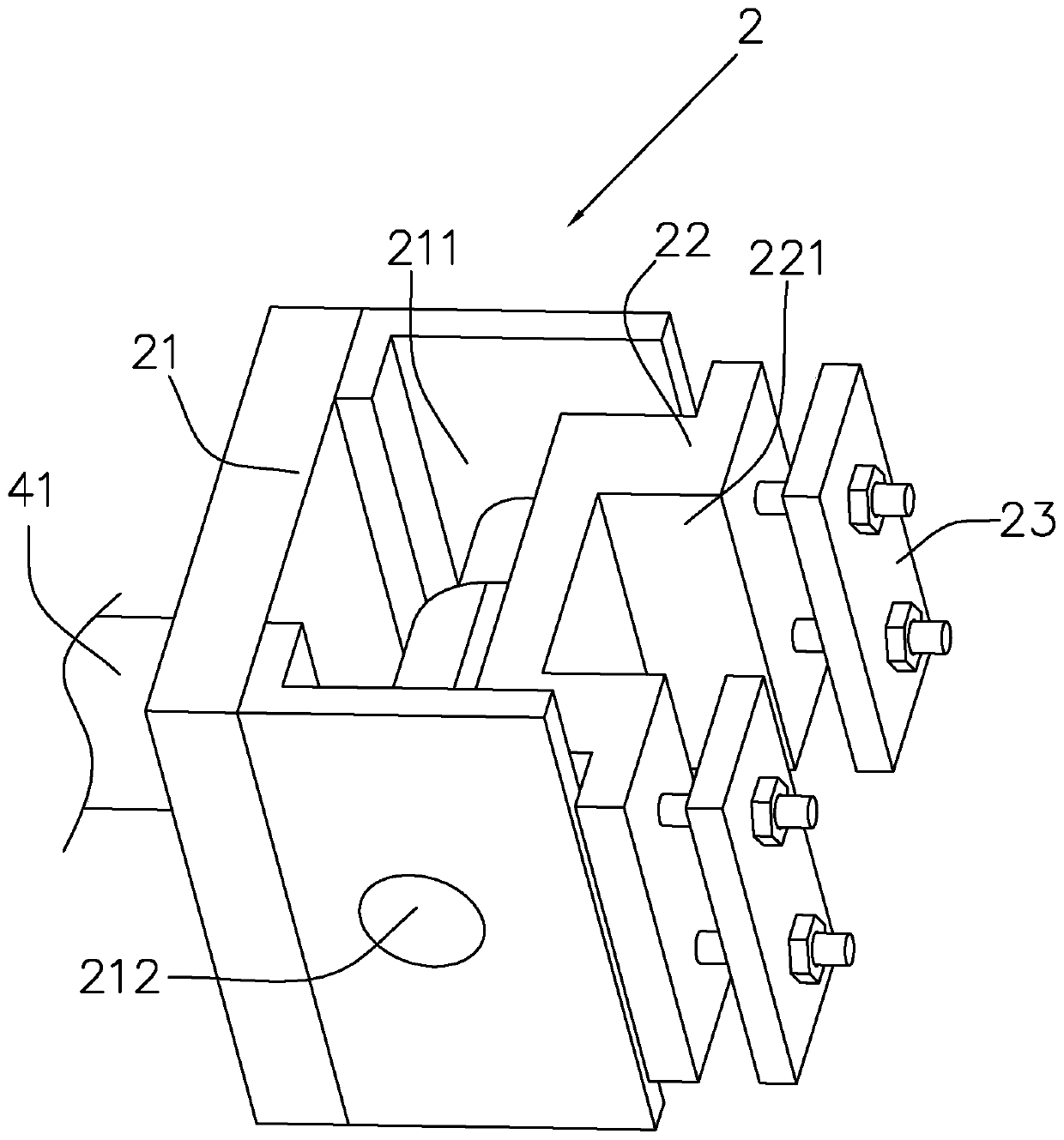

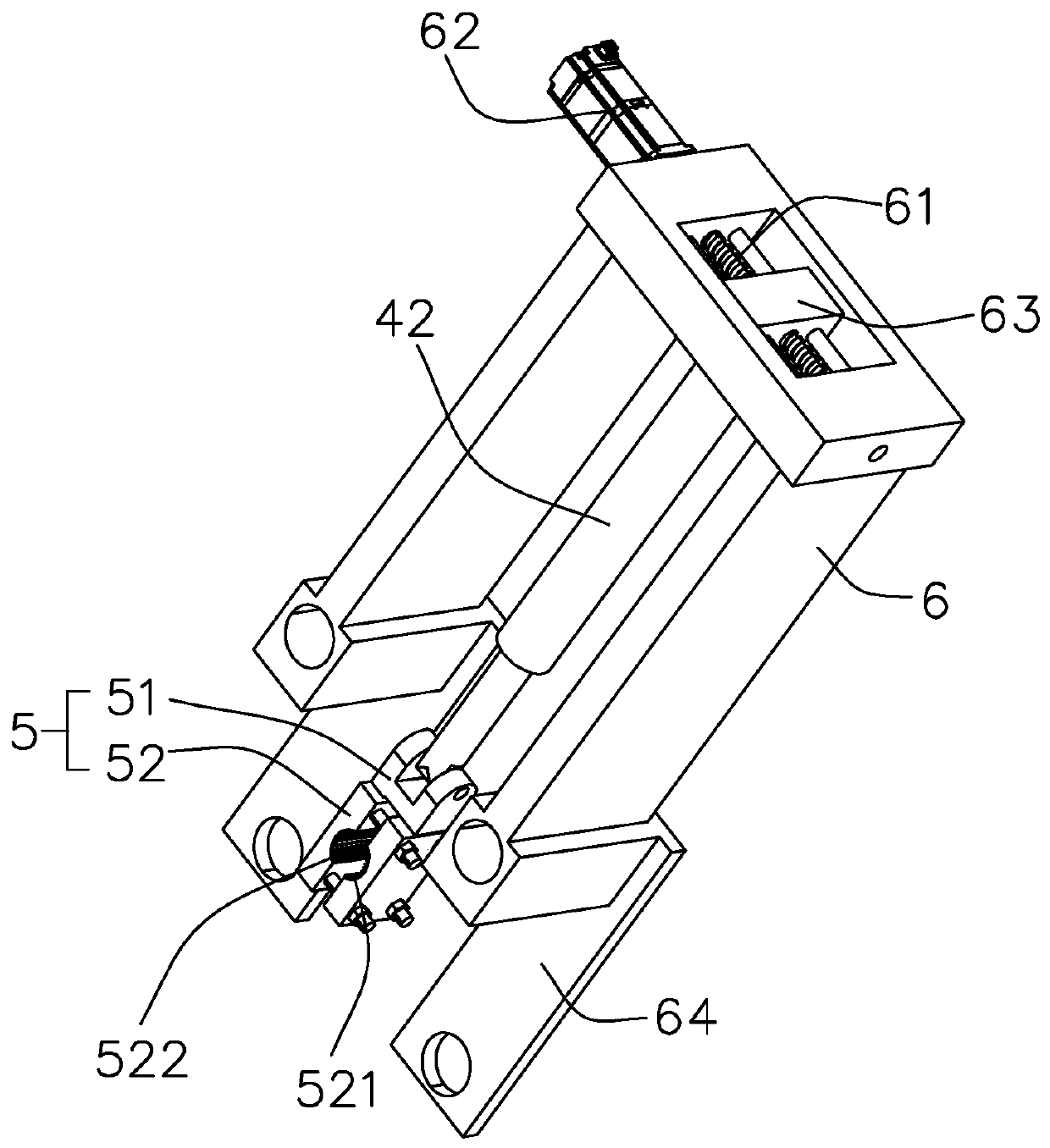

The invention discloses a thrust rod testing machine which comprises a machine body. A first movable arm and a second movable arm are arranged at the two ends of the machine body respectively, a thrust rod is clamped between the first movable arm and the second movable arm. A vertical push cylinder is installed on the machine body, a clamping jaw is hinged to the lower end of the vertical push cylinder, and a clamping gap matching the thrust rod is formed in the clamping jaw. The thrust rod is clamped between the first movable arm and the second movable arm; the thrust rod is clamped on the clamping jaw in the clamping gap, the first movable arm and the second movable arm overturn and swing to conduct force application simulation on the thrust rod, an output shaft of the vertical push cylinder stretches out and draws back, a vertical push-pull force is applied to the thrust rod to simulate the vibration force generated in the vehicle running process. The simulated situation conforms tothe actual running condition, and errors of experiment simulation results are reduced.

Description

technical field [0001] The invention relates to thrust rod testing equipment, in particular to a thrust rod testing machine. Background technique [0002] Thrust rods are important components for heavy trucks and buses to connect the frame and axles and transmit longitudinal and lateral loads. The thrust rod is mainly composed of a head, a shaft and an elastic ball pin, and the two ends are connected together by a steel pipe through hot riveting, and have sufficient connection strength. In order to detect the service life and usage status of the thrust rod, an experimental device is usually required to conduct a simulation experiment on the thrust rod to detect the force and service life of the thrust rod. [0003] The Chinese patent whose notification number is CN2773652Y discloses a kind of vehicle thrust rod simulation experiment device, comprises frame body, has hydraulic drive device and control device on the frame body, and it has a power swing arm and a passive swing...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G01M17/007G01M13/00

CPCG01M13/00G01M17/007

Inventor 傅运军孙立胜高鹏

Owner 烟台辰宇汽车部件有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com